A Method for Restoring Intermediate Junction Points

A repair method and a technology of junction points, applied in the field of intermediate junction point repair and repair, can solve problems such as non-concentric connection holes, and achieve the effects of improving intermediate junction points, reducing wear and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

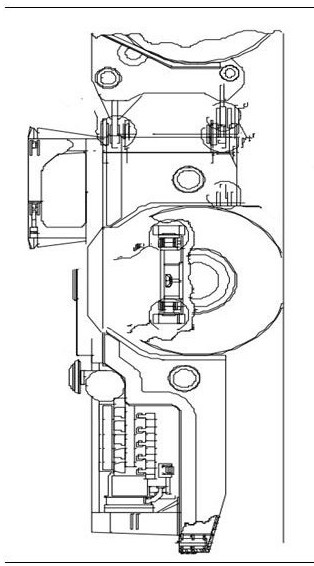

[0029] Embodiment 1: see Figure 1-Figure 7 , a method for repairing an intermediate junction point, the repair method comprising the following steps:

[0030] 1) Rack cleaning; the rack cleaning: classify the front and rear racks of the equipment, rinse them with clean water, and then use a cleaning agent for further cleaning to eliminate oil stains at the intermediate junctions.

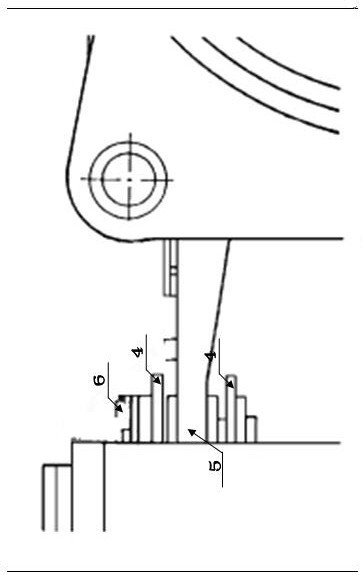

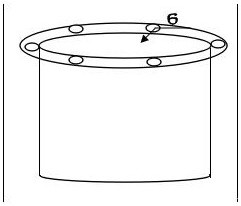

[0031] 2) Design "T" type sinker; the step 2) design "T" type sinker; make "T" type sinker: as image 3 As shown, prepare "T" type countersinking sleeves of the same size, and repair the junction points in the middle of the front and rear racks separately, and the repair method of the front and rear frames is the same. For example, when repairing the junction point in the middle of the front rack, put the "T" type countersink into the connection hole of the junction point in the middle of the equipment rack in turn;

[0032] 3) Design an infrared triangle brace to find the center point device; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com