Up-flow reactor and application thereof

A reactor and upflow technology, applied in chemical instruments and methods, petroleum industry, hydrocarbon oil treatment, etc., can solve problems such as clogging, clogging distributor, uneven distribution of fluid gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

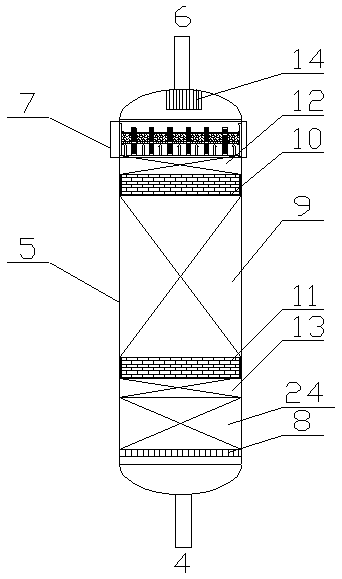

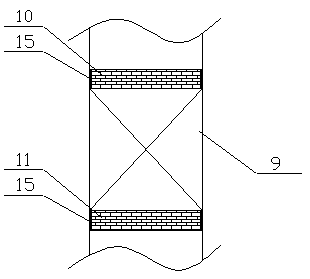

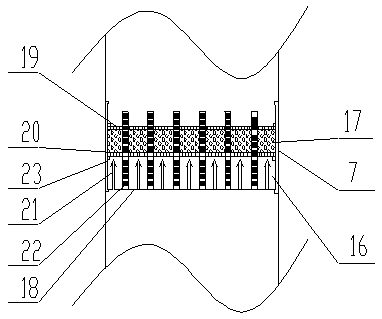

[0044] Using the upflow reactor described in the present invention, the raw material oil and hydrogen are mixed using a conventional static mixer (model SX2.3 / 20-6.4-450), and then the mixture is introduced into the present invention as a reactor feed Upflow reactor (reactor diameter is 100mm), the reactor is filled with catalyst bed supporting grid, protective agent layer 100mm, second ceramic ball supporting layer 60mm, second plastic elastomer bed in sequence along the material flow direction Layer 50mm, catalyst bed 550mm (12-mesh stainless steel wire mesh is laid on top of the catalyst bed), ceramic ball layer 100mm; the catalyst bed support grid is spliced by parallel metal grid strips, and the upper surface of the grid is screened Tiled 20-mesh screen; the second ceramic ball supporting layer is filled with φ20mm inert ceramic balls, and the outside is surrounded by an integrated frame structure made of wire mesh with a wire diameter of 1mm; the second plastic elastome...

Embodiment 2

[0046] Using the upflow reactor of the present invention, the raw material oil and hydrogen are mixed with an inorganic membrane tube disperser. First, the hydrogen is dispersed into microbubbles with a size of 50nm and then penetrates out of the tube to form a reaction with the liquid introduced into the shell. The reactor feed mixture is then introduced into the upflow reactor of the present invention as the reactor feed (the diameter of the upflow reactor is 200 mm); the catalyst bed support grid is filled in the upflow reactor along the direction of material flow , protective agent layer 50mm, catalyst bed layer 600mm, first plastic elastomer bed layer 30mm, first ceramic ball supporting layer 50mm, floating ash removal layer 100mm (the fixed height of the ash filter layer is 50mm, and the internal filling of the fixed interlayer It is made of φ13mm alumina ceramic balls; the filter cartridge shell is made of Johnson mesh, filled with φ3-φ6mm alumina ceramic balls; the tota...

Embodiment 3

[0048] Using the upflow reactor described in the present invention, the raw material oil and hydrogen are mixed using a conventional static mixer (model SX2.3 / 20-6.4-450), and then the mixture is introduced into the present invention as a reactor feed The upflow reactor (reactor diameter is 200mm); the upflow reactor is sequentially filled with catalyst bed support grid, second ceramic ball support layer 30mm, second plastic elastomer bed 80mm, The catalyst bed is 550mm, the first plastic elastomer bed is 80mm, the first ceramic ball supporting layer is 30mm, and the floating ash removal layer is 150mm (the fixed height of the ash filter layer is 75mm, and the fixed interlayer is filled with φ13mm alumina ceramic balls ;The shell of the filter cartridge is made of Johnson mesh, filled with φ3-φ6mm alumina ceramic balls); the total length of the slideway is 180mm; the catalyst bed support grid is spliced by parallel metal grid bars, and the upper surface of the grid is sieved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com