Super-soft high-fluffiness dust removal duster

An ultra-soft and fluffy technology, which is applied in the direction of cleaning carpets, cleaning floors, cleaning equipment, etc., can solve problems that affect product aesthetics, affect product production efficiency, and product hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

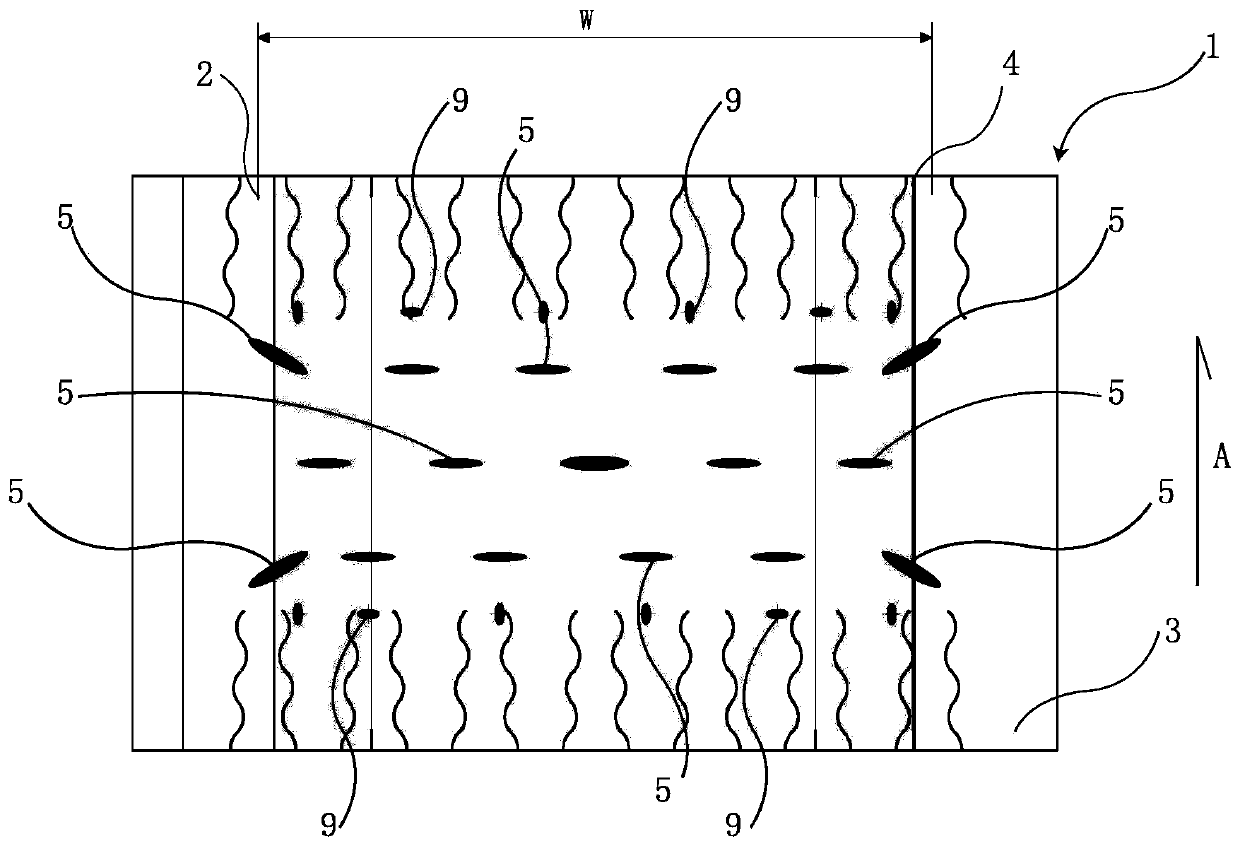

[0039] Such as Figure 1-4, 11 and 12, a kind of ultra-soft and high-fluffy duster 1 comprises a first base material layer 3, a second base material layer 4 and is compounded on the first base material layer 3 and the second base material layer by pressing dot matrix 5 The fiber layer 2 on the layer 4 realizes no continuous pressure line in the middle, so that there is no continuous partition in the middle part of the product, and at the same time, it is ensured that all fibers in the fiber extension direction A have at least one pressure point to fix them on the first substrate layer 3 And on the second base material layer 4, some fibers have two pressing points to fix it on the first base material layer 3 and the second base material layer 4, and the pressing dot matrix makes the fibers be divided into units of different lengths, Fiber bundles of different lengths are formed after the product is cut, and the dot matrix 5 is pressed at the same time to form a handle fixing pa...

Embodiment 2

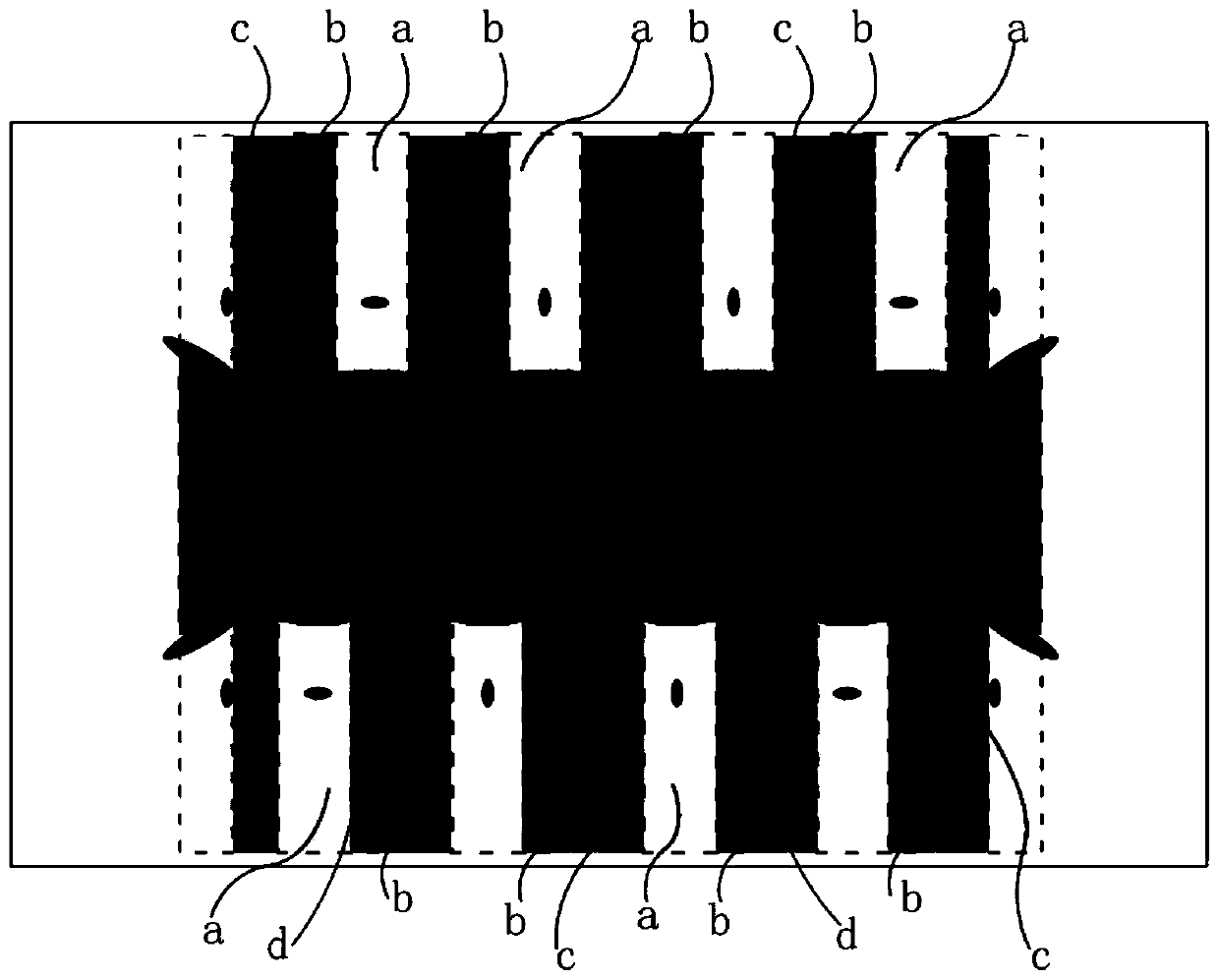

[0041] Such as Figure 5 and 6 As shown, the pressure point matrix 5 includes two rows of pressure points arranged in parallel, and the two rows of pressure points are relatively symmetrically arranged on both sides of the centerline of the product, and the end of each pressure point on one row of pressure points is connected to the other row of pressure points. There is an overlapping part d between the ends of the corresponding pressure points, and the width of the overlapping part d is preferably 0.5mm to 4mm; the pressing point matrix ensures that all fibers in the fiber extending direction are fixed on the base material layer, and the pressing point matrix also makes the A fixing part of the single-insert-piece handle matching the single-insert-piece handle is formed between the substrate layers.

Embodiment 3

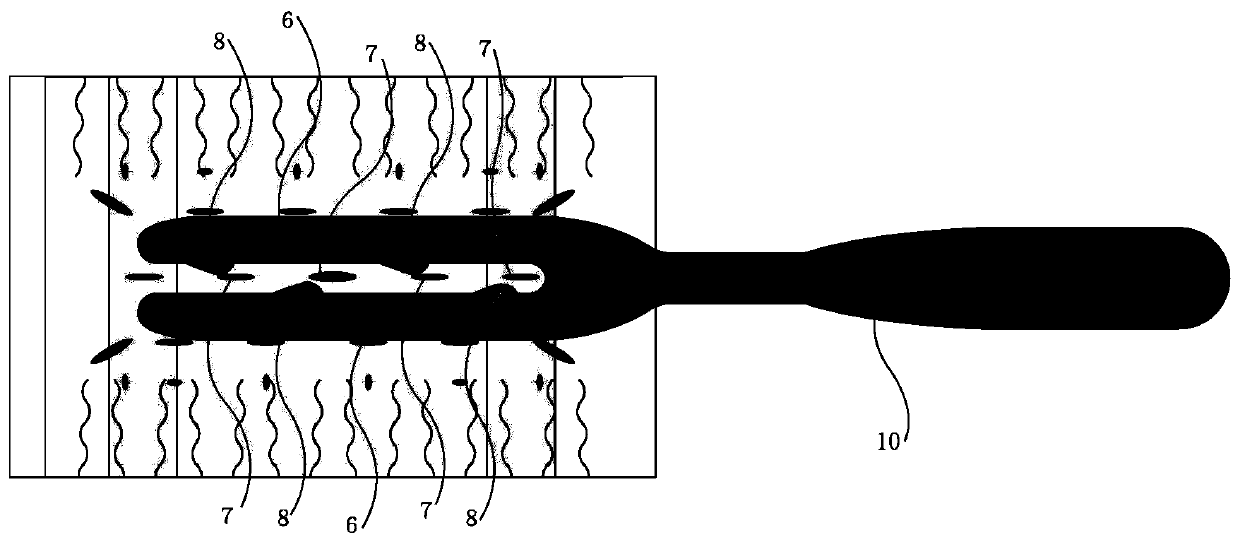

[0043] Such as Figure 7 and 8 As shown, the pressure dot matrix 5 includes four rows of pressure points, the distance between the four rows of pressure points gradually increases from both ends to the middle, and each pressure point end on one of the two rows of pressure points in the middle There is an overlapping part d between the end of the corresponding pressing point on another row of pressing points, and the width of the overlapping part d is preferably 0.5 mm to 4 mm; the pressing point matrix ensures that all fibers in the direction of fiber extension are fixed on the base layer At the same time, pressing the dot matrix also forms a double-insert handle fixing part matching the double-insert handle 10 between the base material layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com