Casing buckling evaluation system in inclined shaft cementing process

An evaluation system and bushing technology, which is applied in the testing of measuring devices, instruments, machines/structural components, etc., can solve the problems of ineffective evaluation of buoyancy effects and unclear effects of bushing effects, etc., and achieves simple structure and good feasibility , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

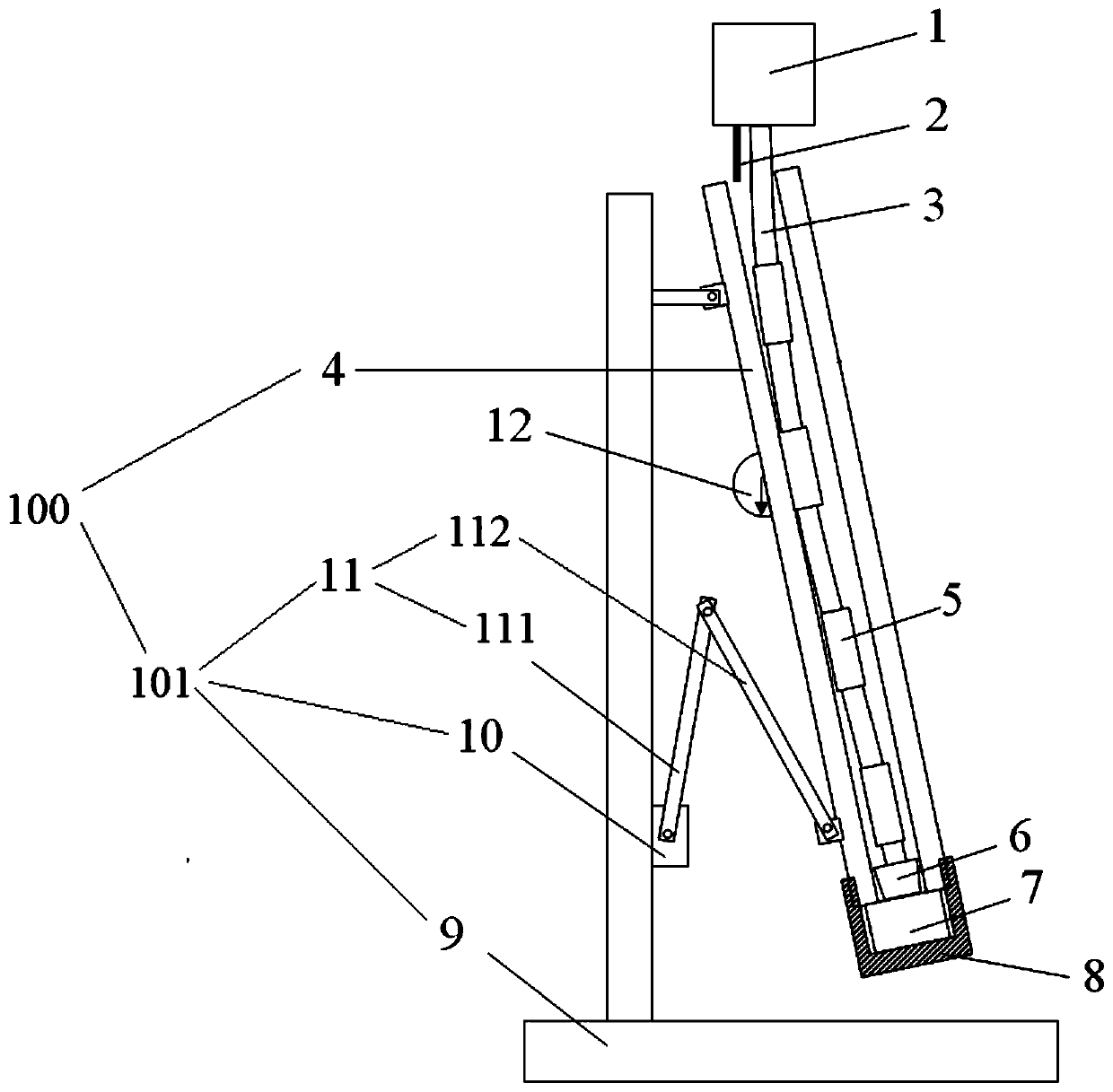

[0035] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0036] The casing buckling evaluation system in the cementing process of deviated wells proposed by the embodiment of the present invention defines a cavity through the borehole wall simulation unit to simulate the borehole wall, and controls the borehole wall simulation unit to be in an inclined state through the inclination control unit to realize deviated well simulation , so that in the process of controlling the flow of cement slurry into the cavity, the hollow casing is affected by the buoyancy of the cement slurry, and the hollow casing is analyzed by detecting the vertical tension, torque and displacement of the hollow casing, and the pressure value detected by the annular pressure sensor. The stress change process of the tube can be used to monitor and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com