Ceramic tee joint suitable for being embedded on intersection position of tee joint of metal pipeline

A metal pipe, junction technology applied to ceramic tees. It can solve problems such as short service life, failure to reach, and wear at the tee, and achieve the effects of improving service life, enhancing wear resistance, and simplifying the seam structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

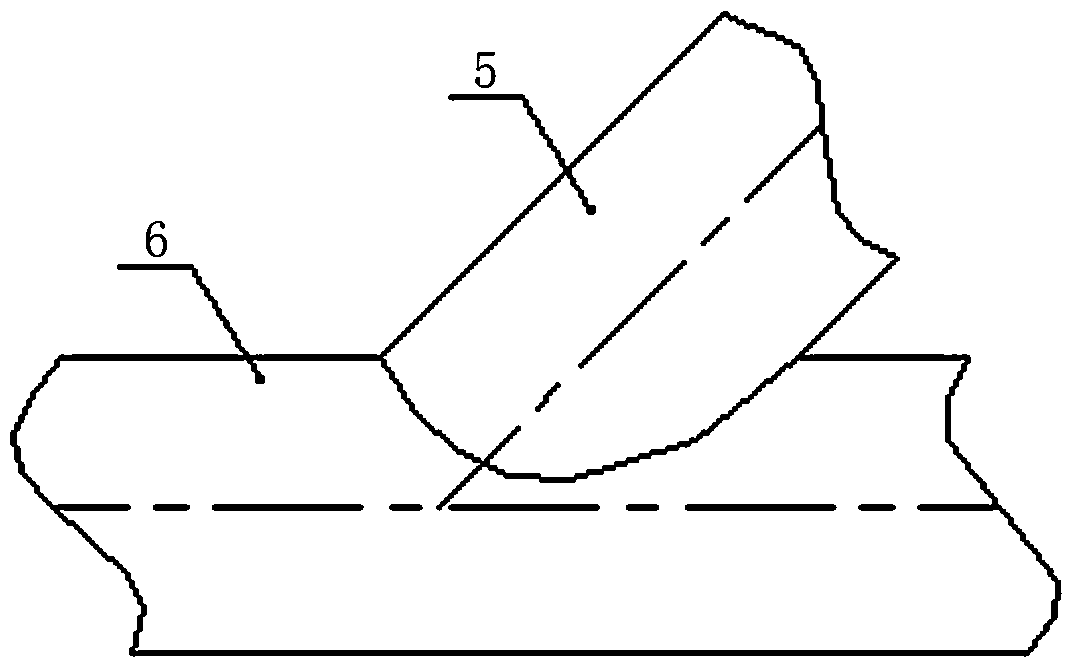

[0029] like Figure 4 , Figure 5 As shown, a kind of ceramic tee suitable for embedding in the intersection of metal pipe tees in Embodiment 1 is composed of ceramic main pipe 3 installed at the intersection of metal pipe tees and embedded in metal main pipe 6, embedded in The ceramic special-shaped pipe 1 in the metal special-shaped pipe 4 and the ceramic branch pipe 2 embedded in the metal branch pipe 5 are converging and connected to form an integral ceramic tee (the integral ceramic tee is made of a high-hardness wear-resistant ceramic material, and the ceramic three-way The service life of the metal pipe tee can be greatly improved after being embedded in the intersection of the industrial metal pipe tee, and it can meet the use requirements of various harsh industrial and mining); the ceramic main pipe 3 is connected with the ceramic special-shaped pipe 1, and the inner cavity is the same and Coaxial arrangement, the ceramic branch pipe 2 is connected with the ceramic ...

Embodiment 2

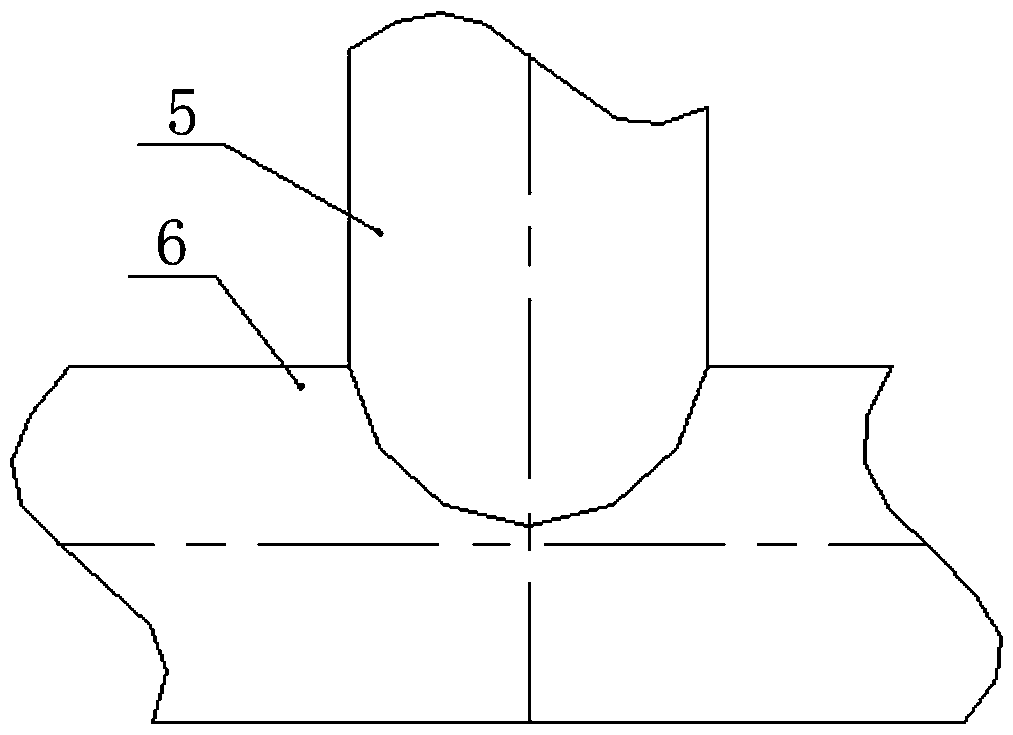

[0034] like Image 6 , Figure 7 As shown, the difference between the second embodiment and the first embodiment: the intersection mode of the ceramic branch pipe 2 and the ceramic special-shaped pipe 1 in the second embodiment is vertical intersection, while the ceramic branch pipe 2 and the ceramic special-shaped pipe described in the first embodiment The intersection mode of 1 is oblique.

Embodiment 3

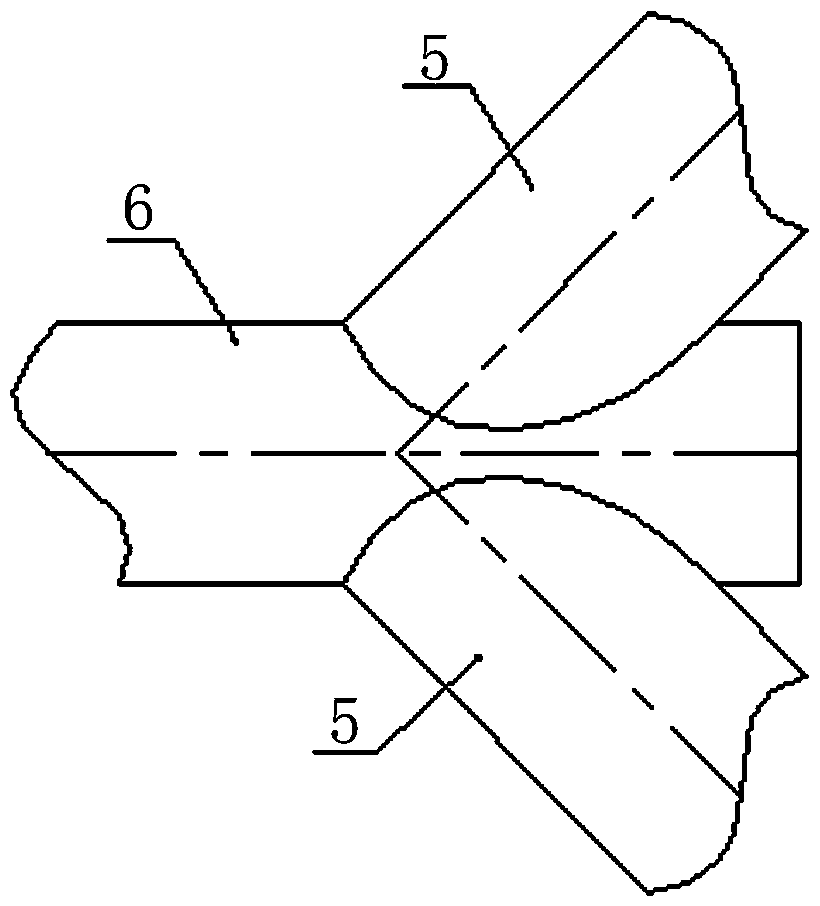

[0036] like Figure 8 , Figure 9 As shown, the difference between the third embodiment and the first embodiment: the number of the ceramic main pipe 3 described in the third embodiment is one, and it is connected to one end (the inlet end or the outlet end) of the ceramic special-shaped pipe 1 in a coaxial manner; There are two ceramic branch pipes 2, both of which are connected to the middle of the special-shaped ceramic pipe 1 in an intersecting manner.

[0037]The specific use of the present invention is as follows (see Figure 10 , Figure 11 ):

[0038] First of all, according to the relative positional relationship of the metal main pipe 6, the metal special-shaped pipe 4, and the metal branch pipe 5 at the intersection of the three-way metal pipe, and the internal diameter cross-section specifications, a combination of the corresponding matching ceramic main pipe 3, ceramic special-shaped pipe 1, and ceramic branch pipe 2 is designed. Then, according to the above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com