Towel coil stirring mechanism and single-motor shuttle type towel device

A technology of single motor and transmission mechanism, which is applied to the mechanism of embroidery machines, auxiliary devices, embroidery machines, etc., can solve the problems of rising embroidery head cost, increasing embroidery head weight, increasing power consumption of other components, etc. Head volume and weight, improve space utilization, reduce the effect of the amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

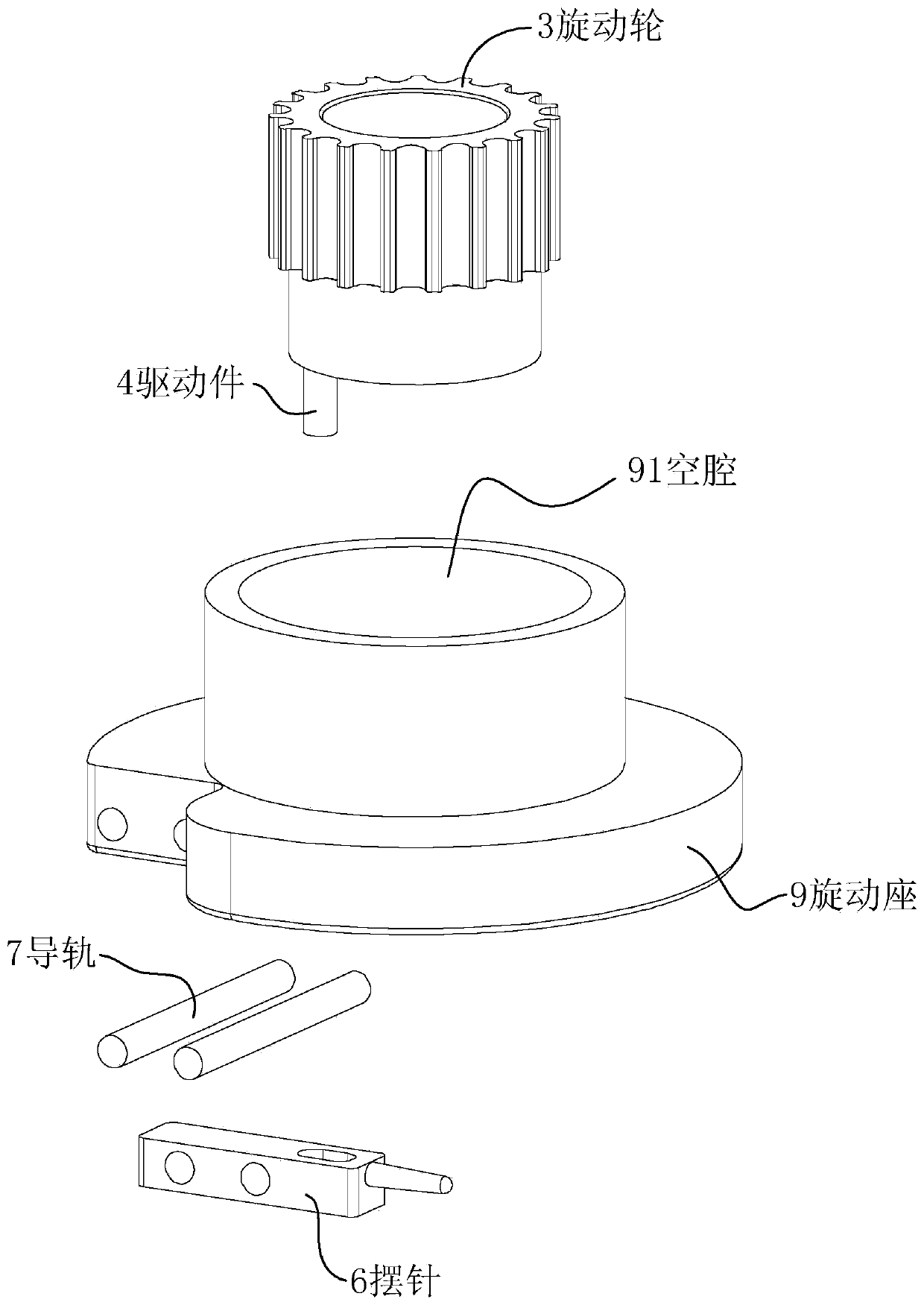

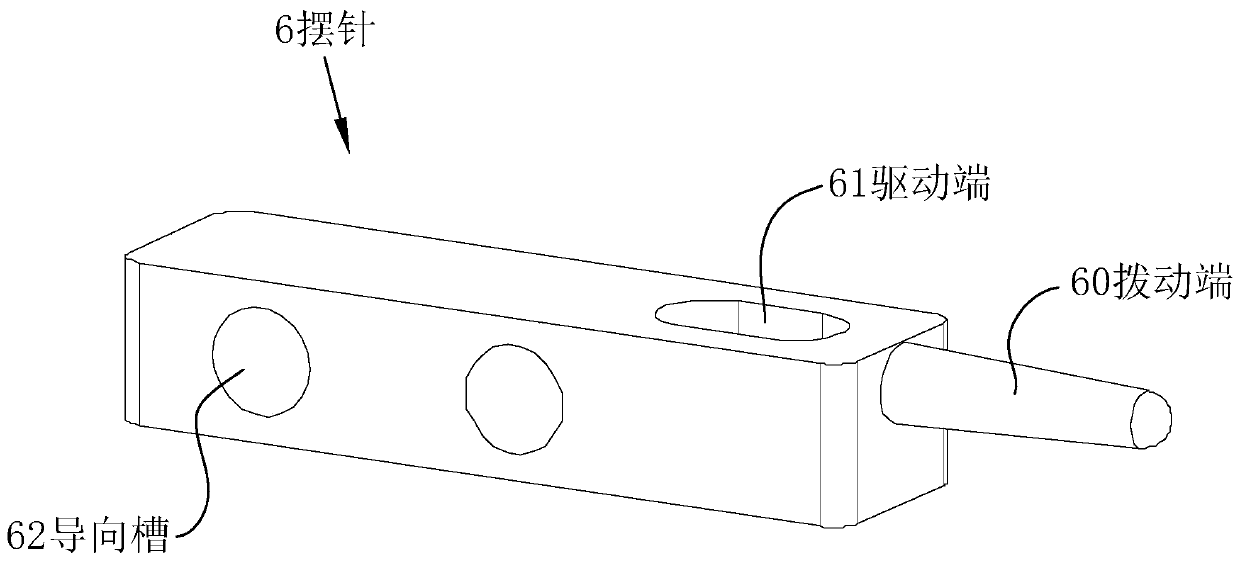

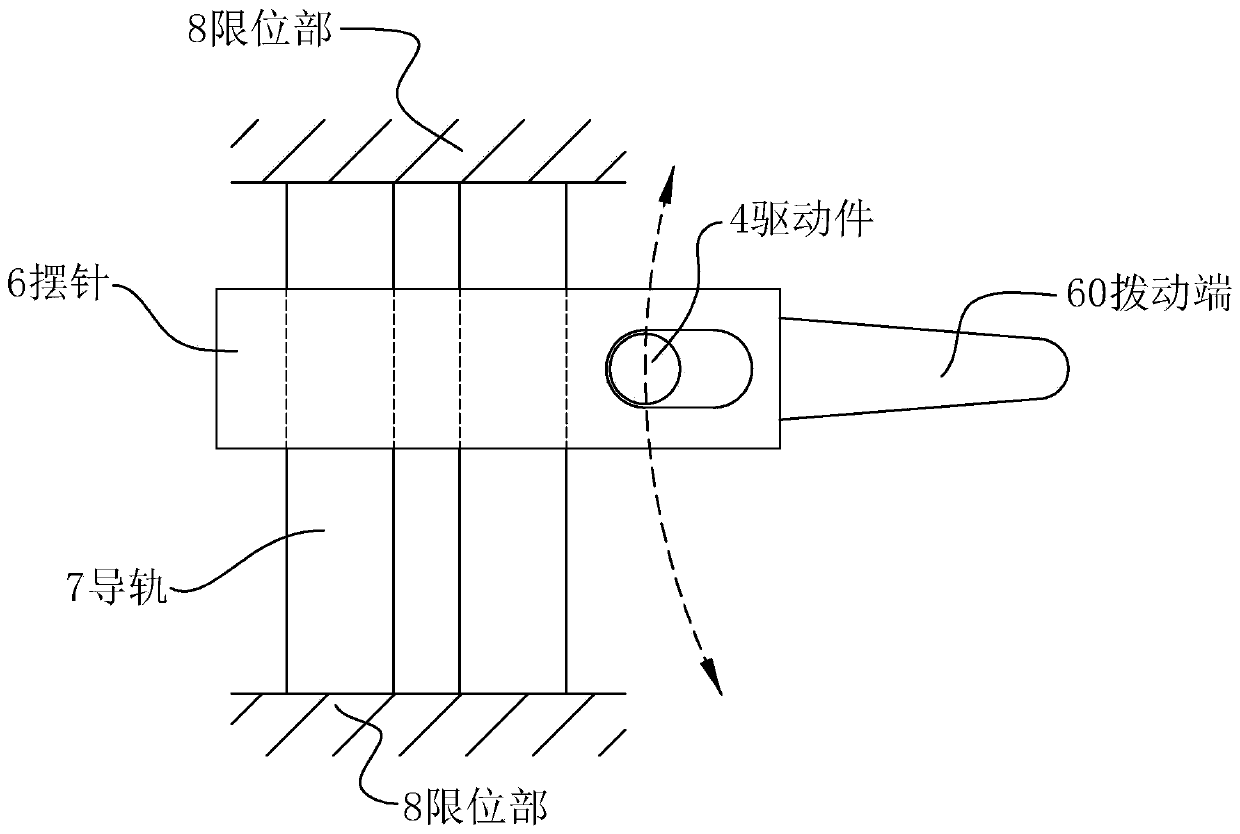

[0059] Such as Figures 1 to 9 The shown single-motor shuttle towel device includes a base 10 , a swing needle 6 , a rotary seat 9 , a driving source 1 , a transmission mechanism and a linkage mechanism. The rotary seat 9 is fixed on the base 10 and rotates relative to the rotary seat 9 .

[0060] Such as figure 1 and Figure 5 As shown, in this embodiment, the driving source 1 adopts a motor. The transmission mechanism includes a driving wheel 2 , a driving belt 20 , a rotating wheel 3 and a driving member 4 .

[0061] The linkage mechanism includes two guide rails 7 and a limiting part 8, and the limiting part 8 is the side wall of the rotary seat 9 at the end of the guide rails 7.

[0062] Such as figure 1 As shown, the middle part of the rotating seat 9 is provided with a cavity 91 for the embroidery machine needle 116 to shuttle, and the rotating seat 9 can rotate along the center of the cavity 91, and the rotating axis of the rotating wheel 3 and the rotating axis ...

Embodiment 2

[0076] In the first embodiment, it is intended to simultaneously complete the two operations of "coil switching" and "direction adjustment" through a single machine.

[0077] Such as Figure 10 and Figure 11 As shown, in this embodiment, an additional auxiliary motor 1' is added to assist the steering of the swivel seat 9, and the auxiliary motor 1' is mainly responsible for "direction adjustment".

[0078] The motor 1 is mainly responsible for "coil switching" and secondly "direction adjustment".

[0079] When turning slightly, the "direction adjustment" can be carried out by the motor 1, and when turning sharply, the auxiliary motor 1' can be used to accelerate the turning.

[0080] At the same time, after the auxiliary motor 1' is added, the motor 1 can also pick hair while turning, so as to achieve the purpose of "coil switching" and "direction adjustment" at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com