Laminating device

A lamination device and lamination technology, applied in lamination devices, layered products, lamination, etc., can solve problems such as sheet warping, sheet deviating from the positioning groove, and sheet position error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

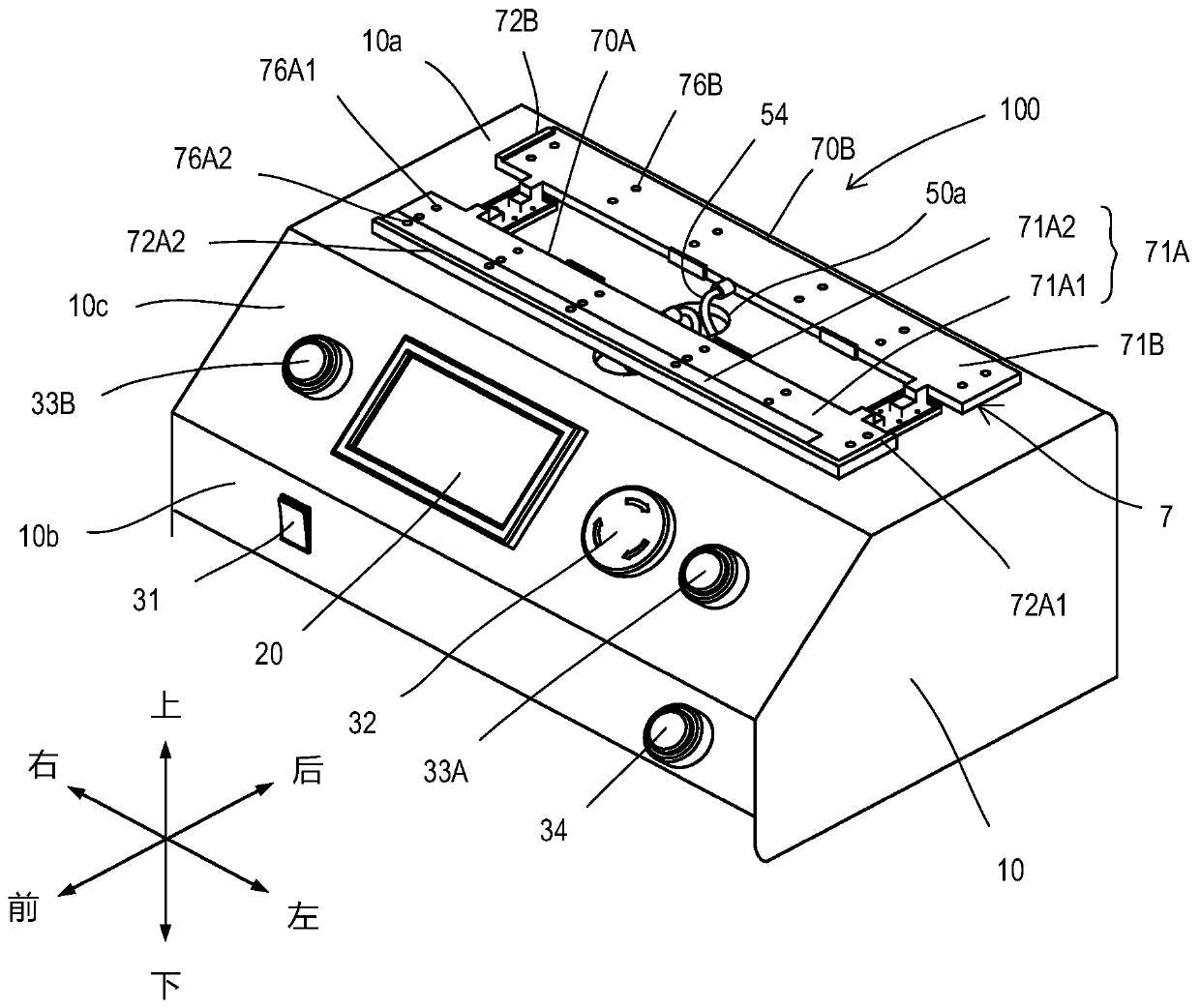

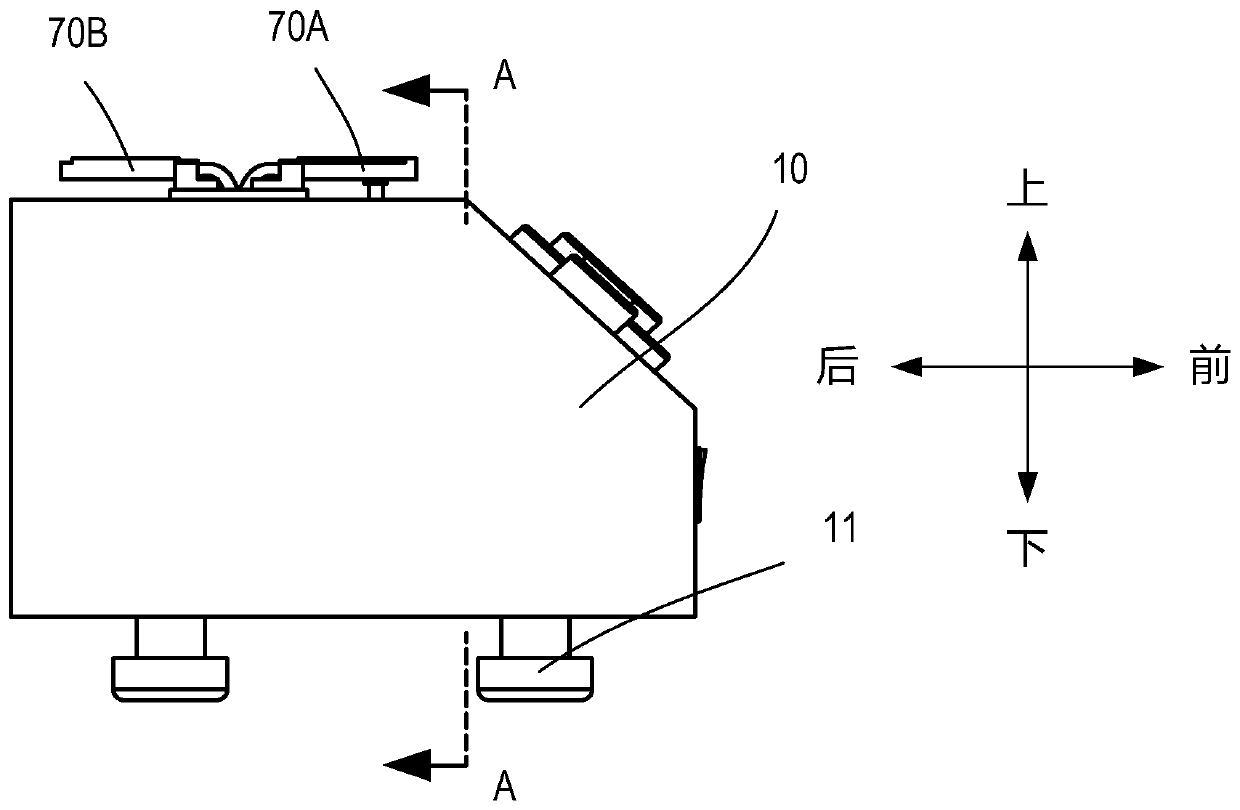

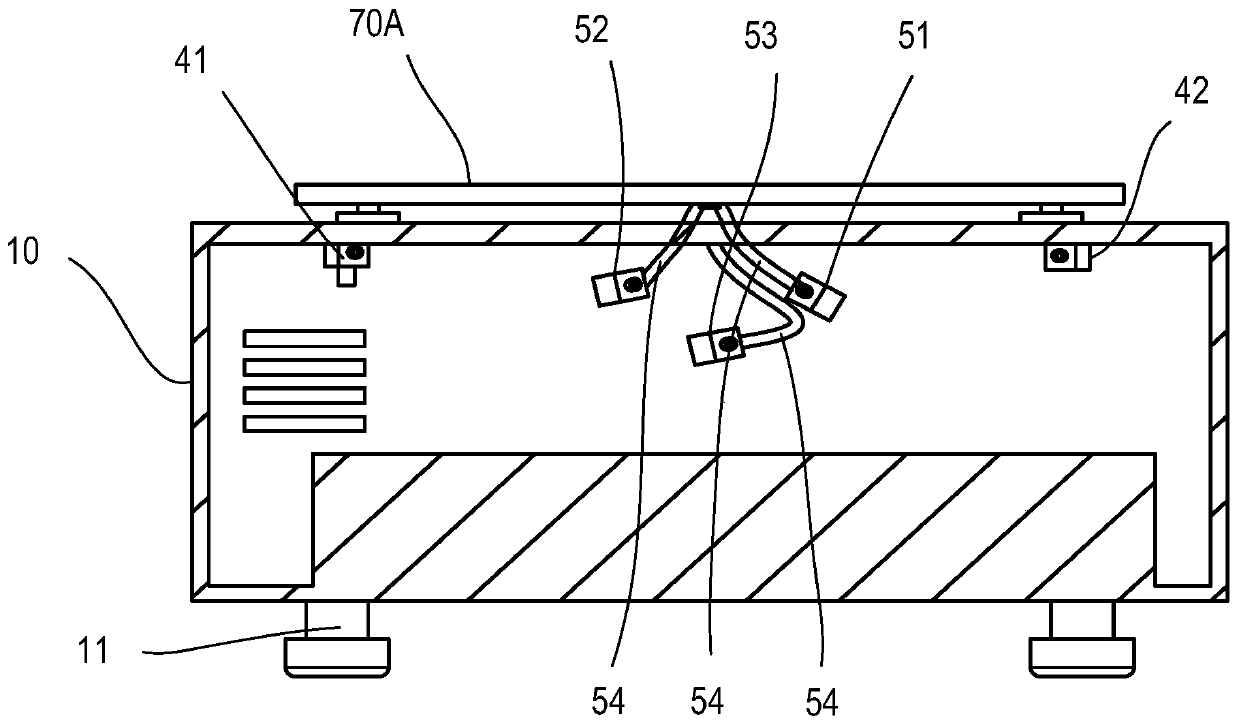

[0039] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0040]

[0041] Before describing the test paper laminating device, the structure of the test paper will be described. Image 6 It is a front view of the rigid contact lens fitting test paper concerning this embodiment. like Image 6 As shown, the rigid contact lens fitting test paper 300 has a handle part 301 and a dyed filter paper part 302. The handle part 301 is for the operator to grasp, and it is composed of two pieces of handle paper with the same shape (only one piece can be seen in the figure, The other piece is covered by it), and these two pieces of handle constitute paper to clamp the dyed filter paper part 302 from both sides so as to hold it.

[0042] Figure 7 Shown is the front view of the semi-finished test paper, which can be produced by the above-mentioned test paper bonding device. like Figure 7 As shown, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com