Centrifugal clutch

A centrifugal clutch and clutch technology, applied to clutches, automatic clutches, transmissions, etc., can solve the problems of small clutch capacity, lower fuel consumption rate, and complicated configuration, and achieve the effect of reducing the burden of production and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

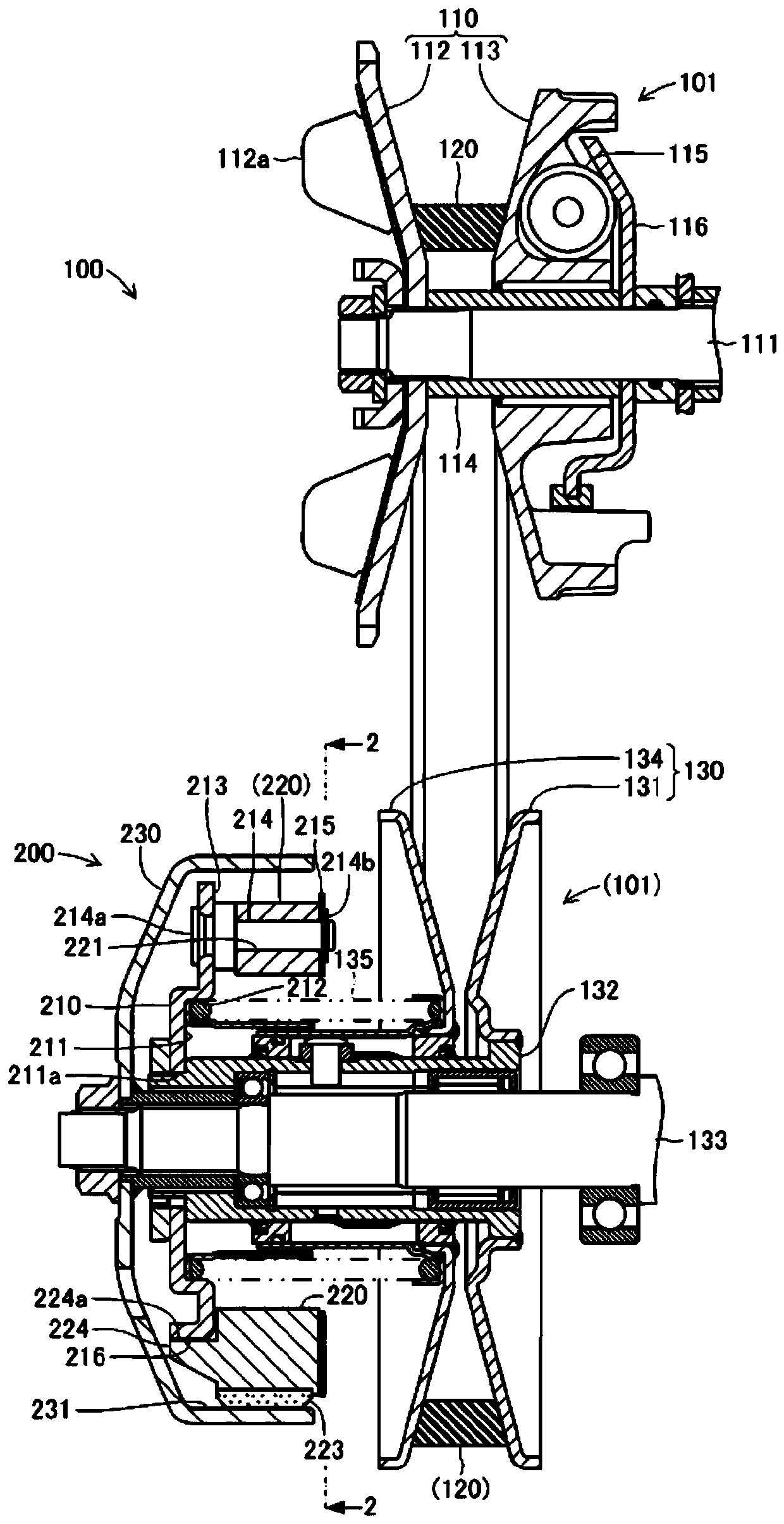

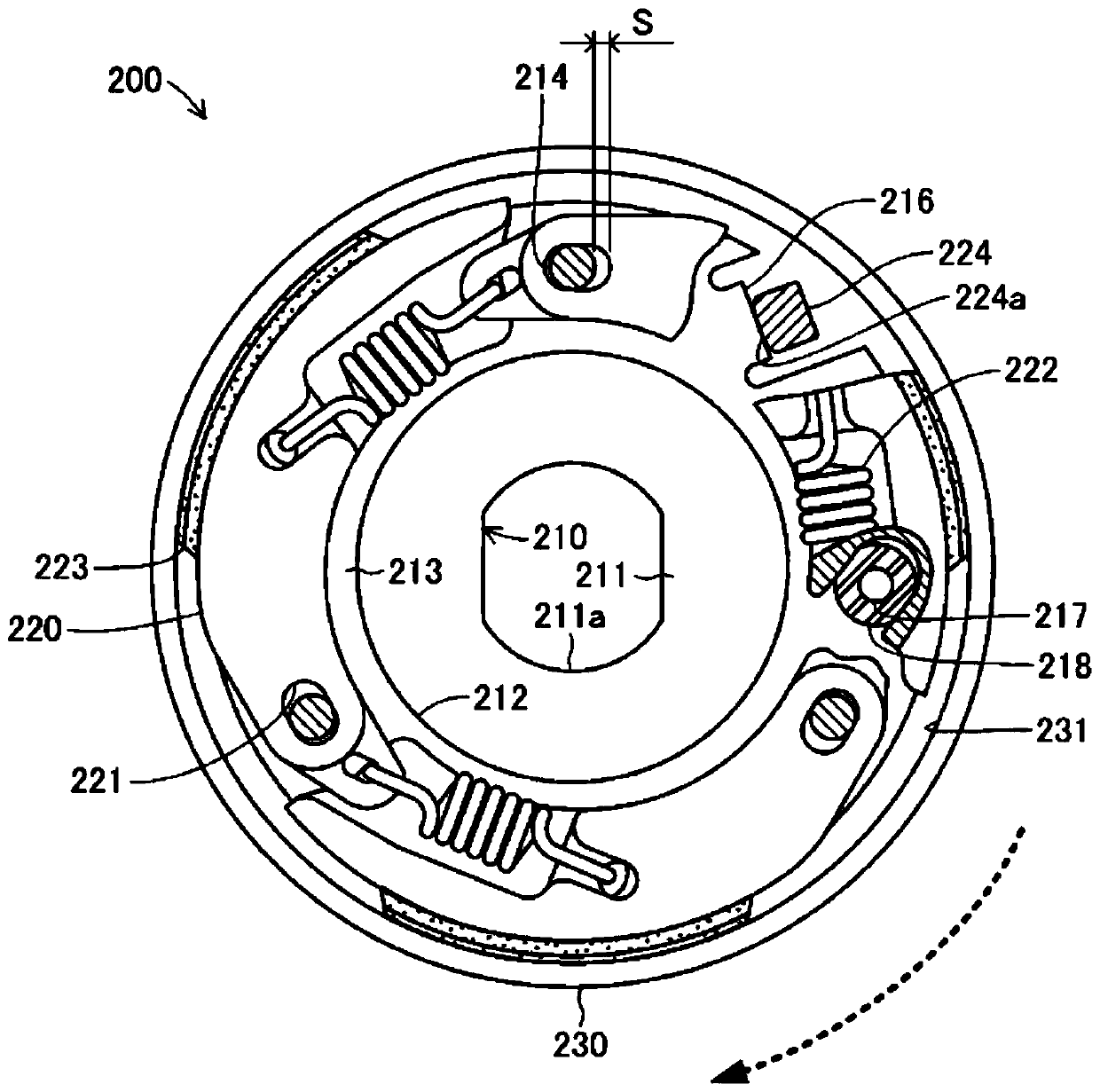

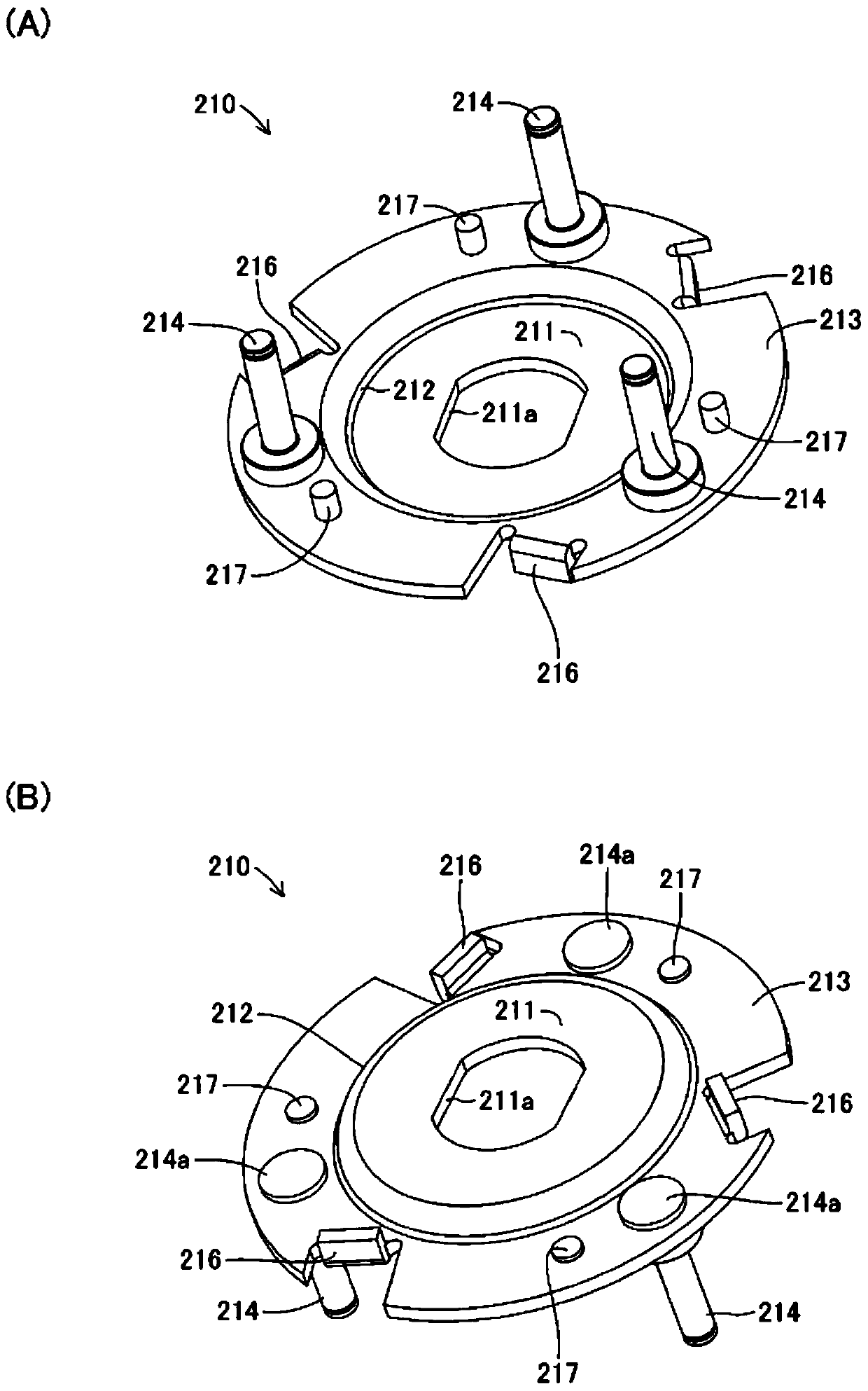

[0058] One embodiment of the centrifugal clutch according to the present invention will be described below with reference to the drawings. figure 1 It is a top sectional view schematically showing the configuration of the power transmission mechanism 100 including the centrifugal clutch 200 of the present invention. again, figure 2 By figure 1 A side view of the centrifugal clutch 200 is shown on line 2-2. The power transmission mechanism 100 including the centrifugal clutch 200 is a mechanical device that is installed between the engine and the rear wheels as drive wheels mainly in a motorcycle such as a scooter, and automatically changes the speed reduction ratio with respect to the number of revolutions of the engine. Transmit or block the rotational driving force on the rear wheel.

[0059] (Configuration of Centrifugal Clutch 200)

[0060] This power transmission mechanism 100 mainly includes a transmission 101 and a centrifugal clutch 200 . The transmission 101 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com