Self-heat-dissipation type power cabinet

A power cabinet and self-heating technology, which is applied to electrical components, substation/power distribution device shells, substation/switch layout details, etc., can solve problems such as poor ventilation, poor use of electrical appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

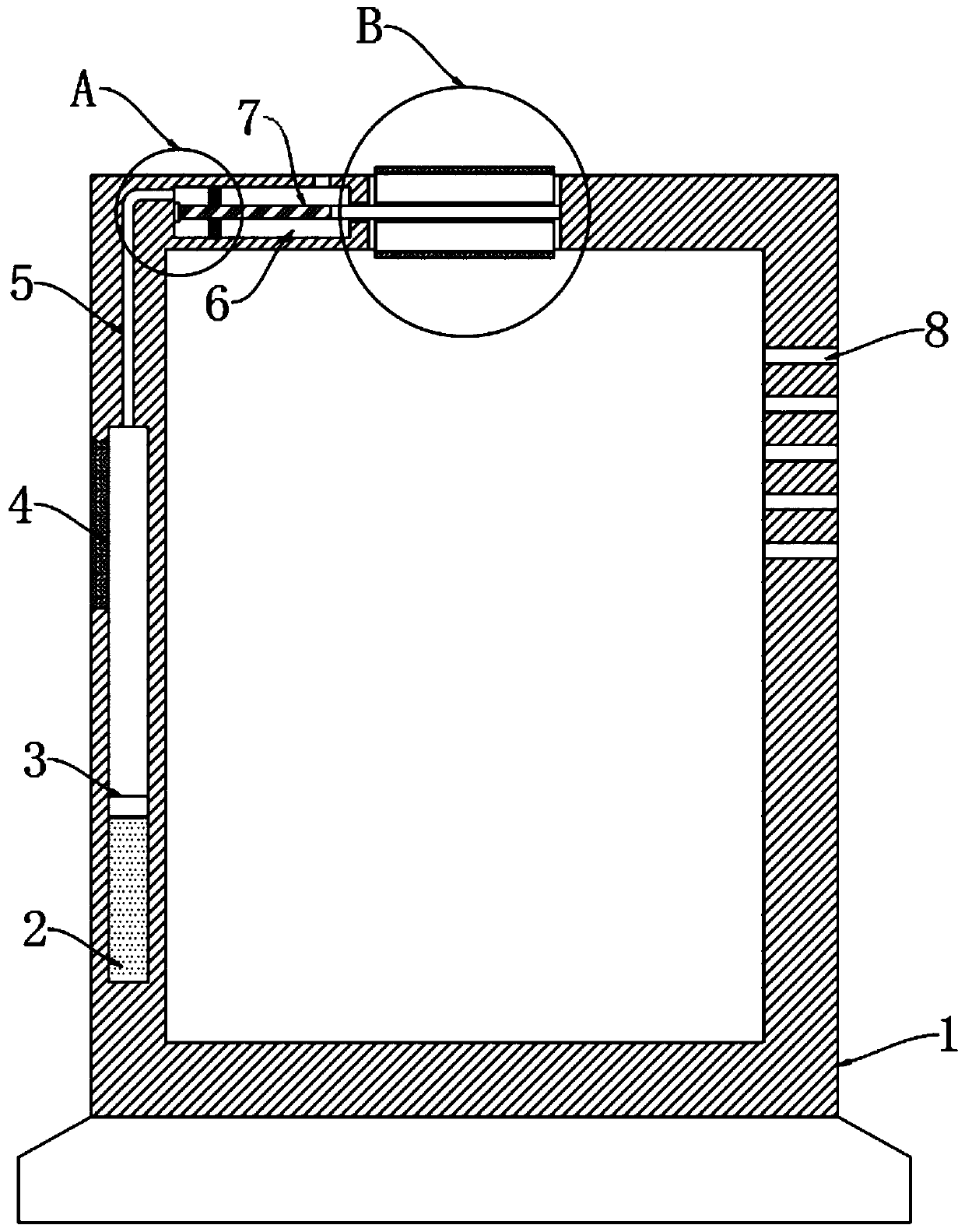

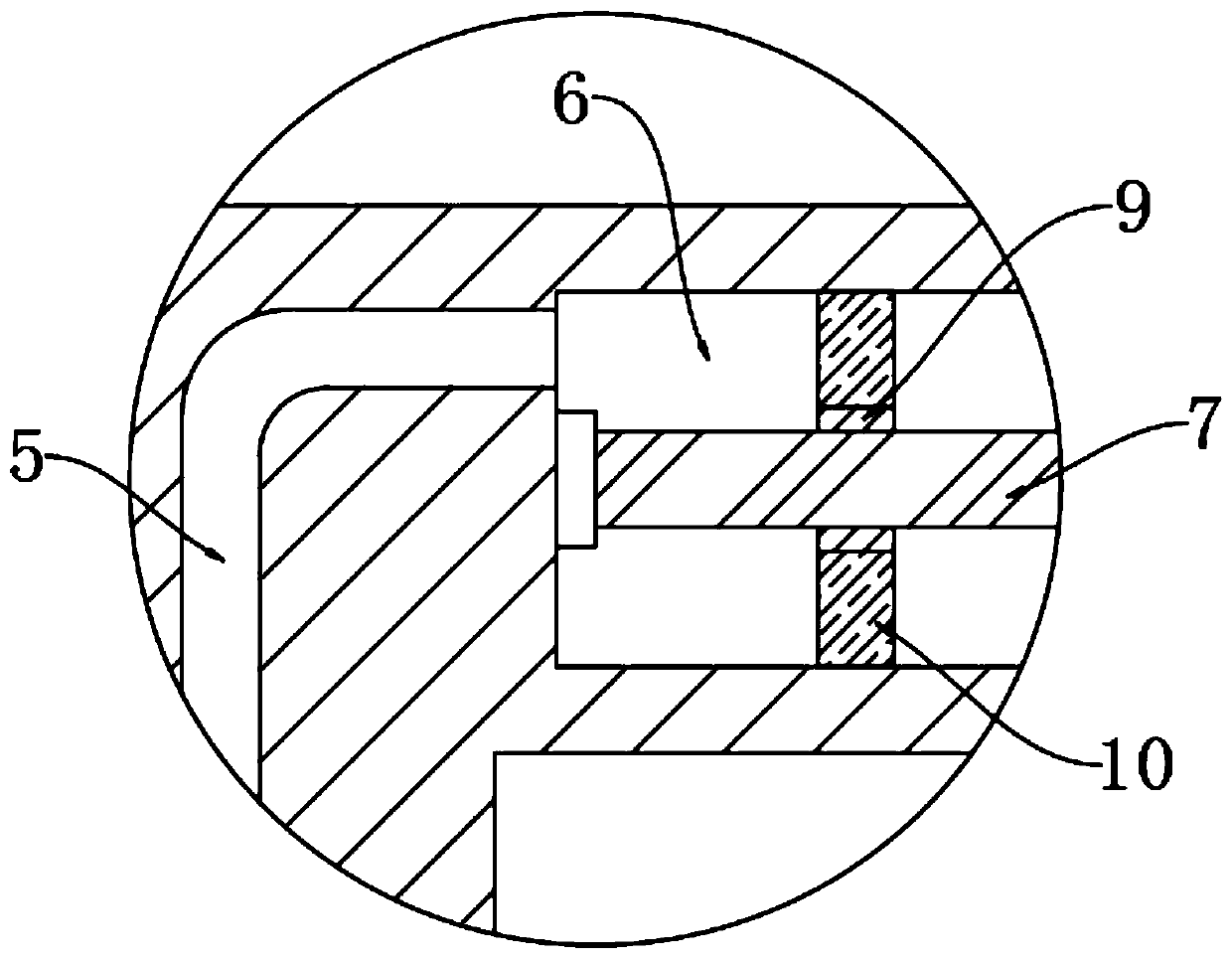

[0024] refer to Figure 1-4 , a self-radiating power cabinet, including a cabinet body 1, a cavity 2 is provided in the side wall of the cabinet body 1, a sliding plug 3 is sealed and slidingly connected between the inner walls of the cavity 2, and the lower end of the cavity 2 and the sliding plug 3 The space is filled with evaporative liquid, and a heat conducting plate 4 is embedded at the upper end of the corresponding cavity 2 on the side wall of the cabinet body 1 .

[0025] Further, the evaporating liquid adopts trichloromethane, and the boiling point temperature of trichloromethane is 61°C-62°C, while the conventional working temperature of electrical components in the power cabinet is -20°C-60°C, so when the temperature in the cabinet 1 is too high When it is close to or even exceeds 60°C, the evaporating liquid starts to evaporate.

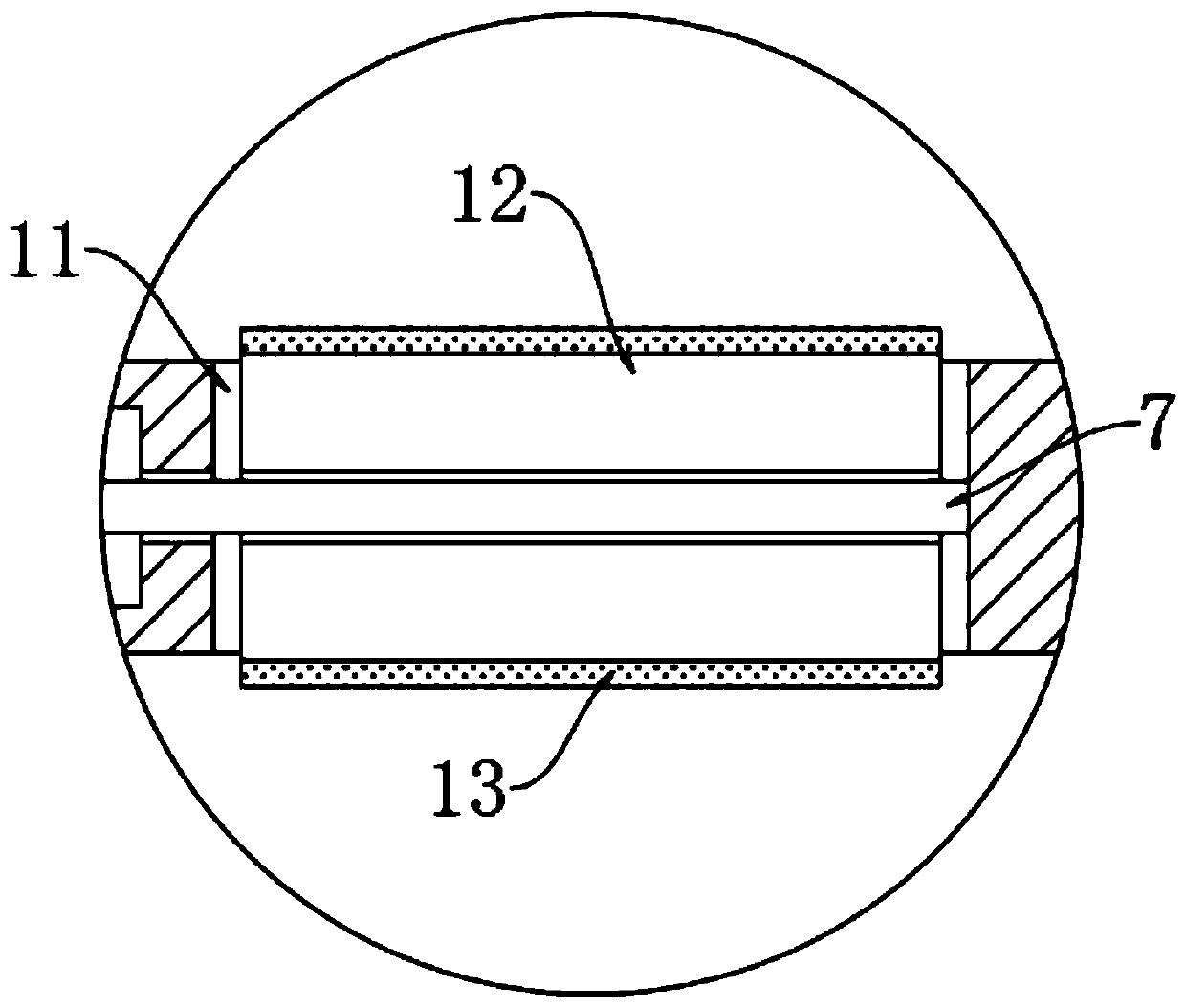

[0026] The upper side wall of the cabinet body 1 is provided with a rectangular installation opening 11, and the installation opening ...

Embodiment 2

[0035] refer to Figure 5-6The difference from Embodiment 1 is that: the top of the cabinet body 1 is provided with an air outlet hole 15 communicating with the end of each device chamber 6 near the installation port 11, and the air outlet hole 15 is equipped with a device that only allows air to flow from the inside of the cabinet body 1 to The one-way valve in the device cavity 6, the one-way valve that only allows air to flow from the device cavity 6 to the outside of the cabinet body 1 is installed in the vent hole 14 .

[0036] In this embodiment, when the annular sliding plug 10 slides to the left, negative pressure is generated in the device chamber 6, and the hot air in the cabinet 1 flows into the device chamber 6 from the air outlet 15. When the annular sliding plug 10 slides to the right , the hot air in the device cavity 6 is discharged from the vent hole 14, and the hot air in the cabinet body 1 can be continuously discharged with the continuous reciprocating slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com