Bilateral mesh control method of full-automatic computerized flat knitting machine

A computerized flat knitting machine and control method technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of complex control process and inability to effectively eliminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

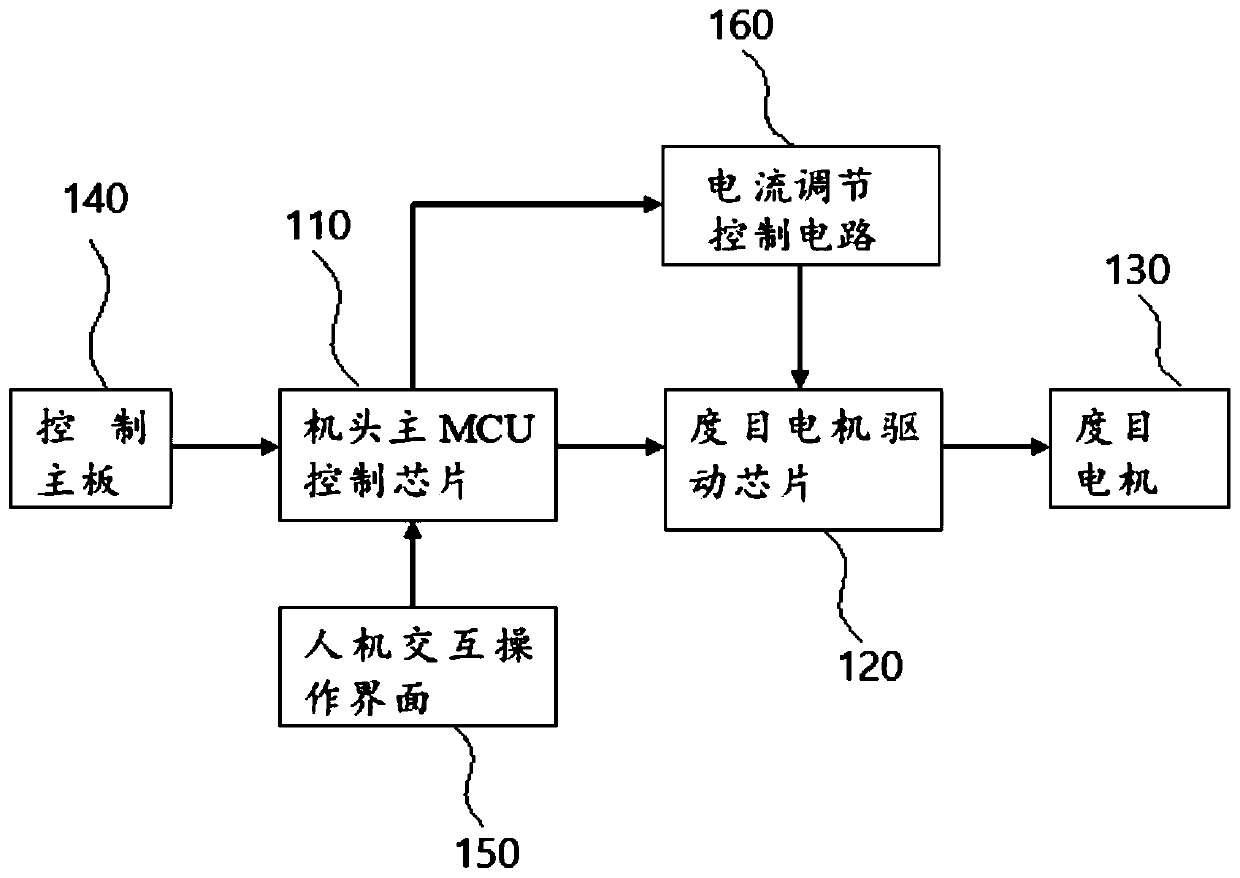

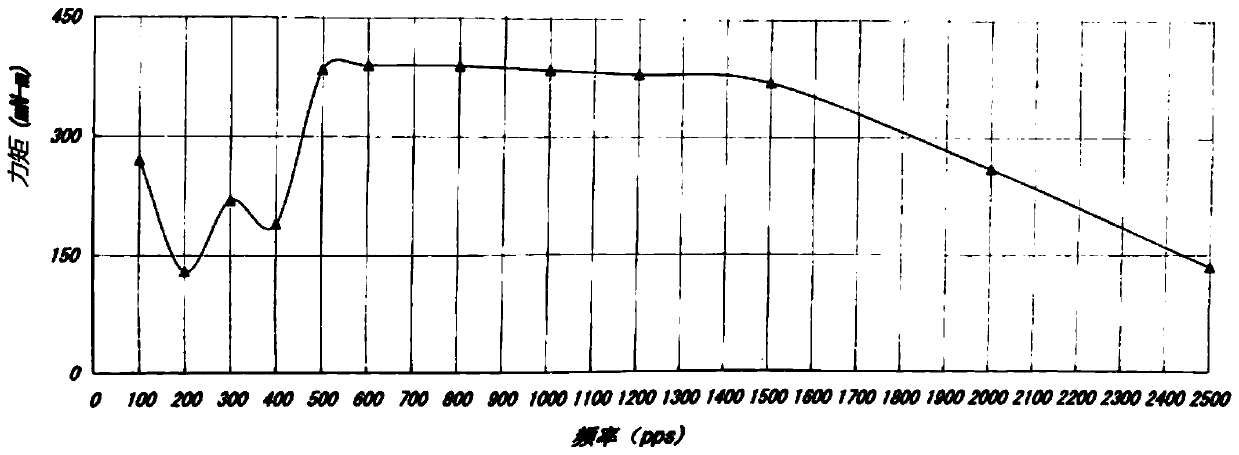

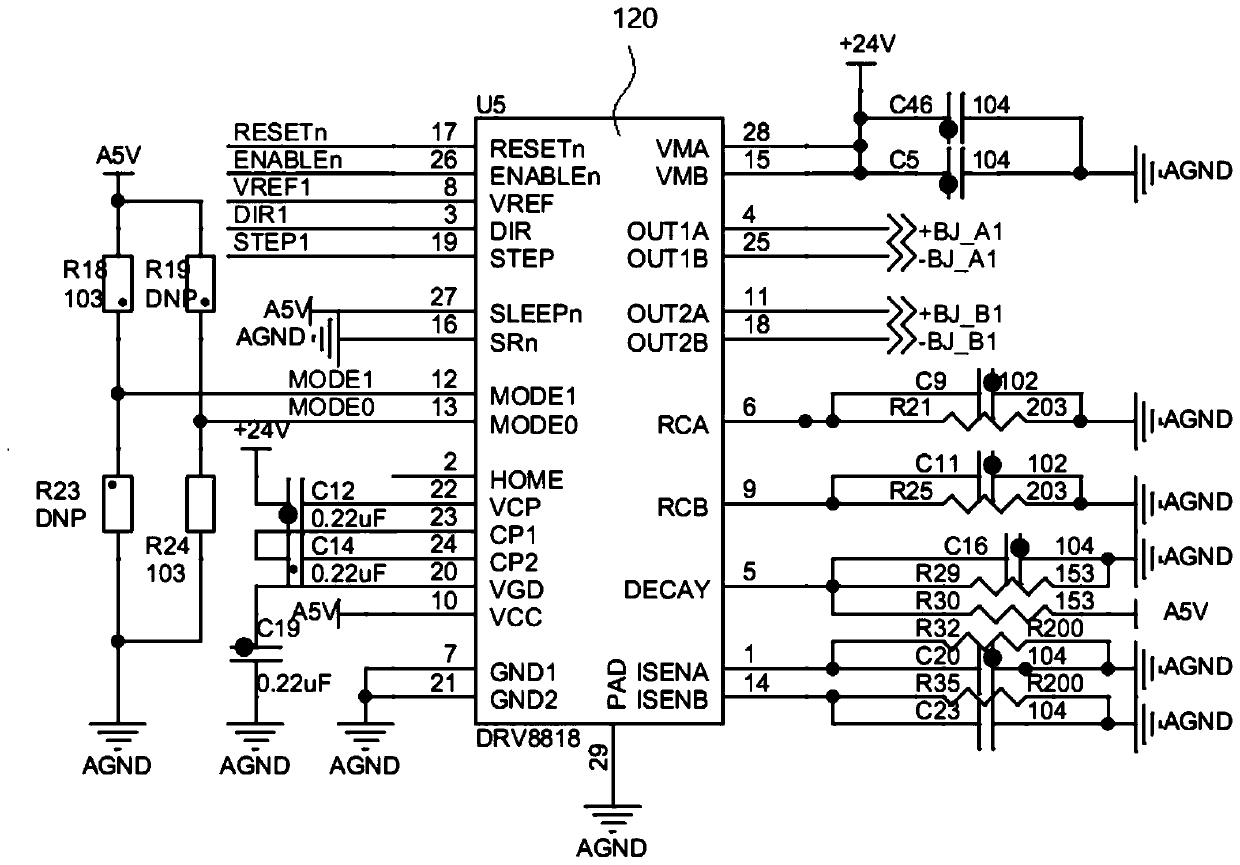

[0044] The embodiment of the invention discloses a double-sided stitch control method for a fully automatic computerized flat knitting machine. The fully automatic computerized flat knitting machine includes a main MCU control chip of the machine head and a stitch motor drive chip. The adjustment of the needle pressing range is used to realize the adjustment of the coil size of the knitted clothing, and the target position requirement of the stitch change of the knitted clothing is set as: for the same row of knitted clothing, the knitting of the two sides of the row and at least one needle position away from it The stitch value of the segment position is at least 2 characters lower than the preset stitch value of the row of knitted clothes, and the stitch change target position requirements of the knitted clothes are pre-inputted into the main MCU control chip of the machine head; the main MCU control chip of the machine head According to the target position requirement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com