Occlusion mechanism and occlusion method after bending of coil leading-out wire end

A technology for lead-out wires and wire ends, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., and can solve problems such as being unable to adapt to automated production operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

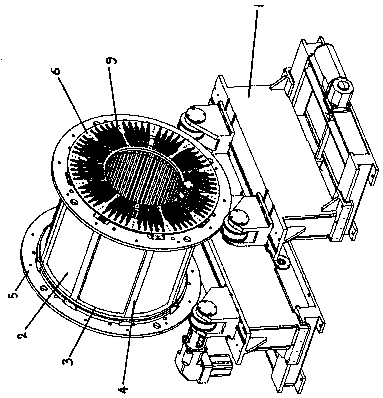

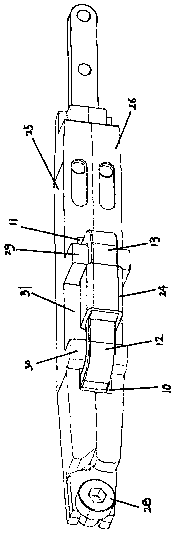

[0028] A occlusal mechanism after the lead-out wire end of a coil is bent, including a servo roller bracket 1, on which a stator core 2 is movably arranged, and the stator core 2 is movably erected on the servo roller bracket through tooling rings 5 on both sides 1, the tooling ring 5 is connected with a double-ring support plate 6 for installing lead line positioning and bending tooling, and a butt joint is arranged between the inner ring plate 7 and the outer ring plate 8 of the double-ring support plate 6. Together with the positioning strip 9, in the positioning piercing hole 10 of the inner ring lead-out line on the positioning strip 9, the inner ring lead-out line is passed through the bending thread head 12, and the outer ring on the positioning strip 9 is drawn out In the line positioning piercing hole 11, the outer ring lead-out line is pierced with a bent thread en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com