Electric connection structure and connector thereof

A technology of electrical connection structure and connector, applied in the direction of connection, components and circuits of connecting devices, can solve the problem of limited screw connection structure settings, and achieve the effect of electric field optimization, optimization of electric field, and avoidance of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

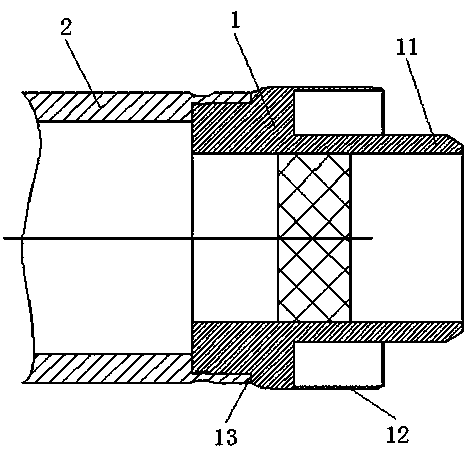

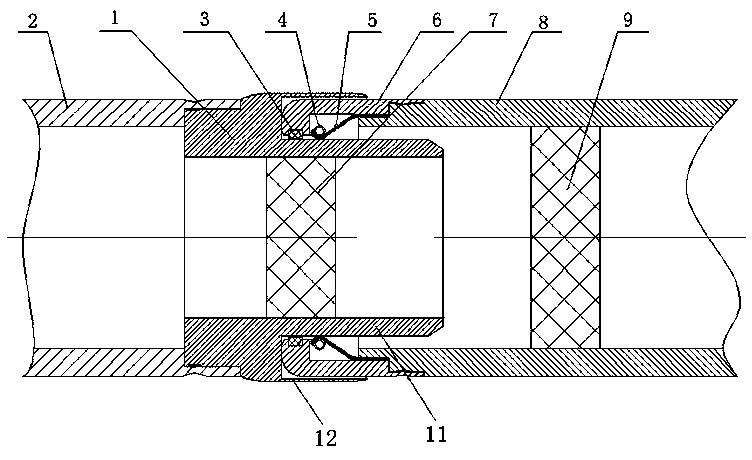

[0046] Embodiment 2 of the connector of the present invention. The difference between this embodiment and Embodiment 1 of the connector is that in Embodiment 1, the cylindrical shielding structure is a straight cylinder. In this embodiment, the cylindrical shielding structure has The arc-shaped barrel structure has a more arc-shaped transition shape, which can optimize the electric field of the connector.

Embodiment 3

[0047] Embodiment 3 of the connector of the present invention, the difference between this embodiment and Embodiment 1 of the connector is that, in Embodiment 1, the end of the conductive rod at the connector end is sleeved on the connecting step of the connector, and the two In this embodiment, the end face of the conductive rod at the connecting head end is abutted with the end face of the connecting head, and the conductive rod at the connecting head end is welded together with the connecting head.

Embodiment 4

[0048] Embodiment 4 of the connector of the present invention, the difference between this embodiment and Embodiment 1 of the connector is that in Embodiment 1, the connector is formed by cutting from a forging, and in this embodiment, the connector is made of a tubular The profile is formed by cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com