Fabricated wind power tower quick assembling device and construction method

A technology for wind power towers and assembling devices, which is applied to portable lifting devices, installation/supporting wind turbine configurations, hoisting devices, etc., and can solve problems such as high requirements for construction organization, large assembly area, and large differences in terrain and landforms , to achieve the effects of easy control of assembly quality, reduction of construction site occupation area, and reduction of land cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

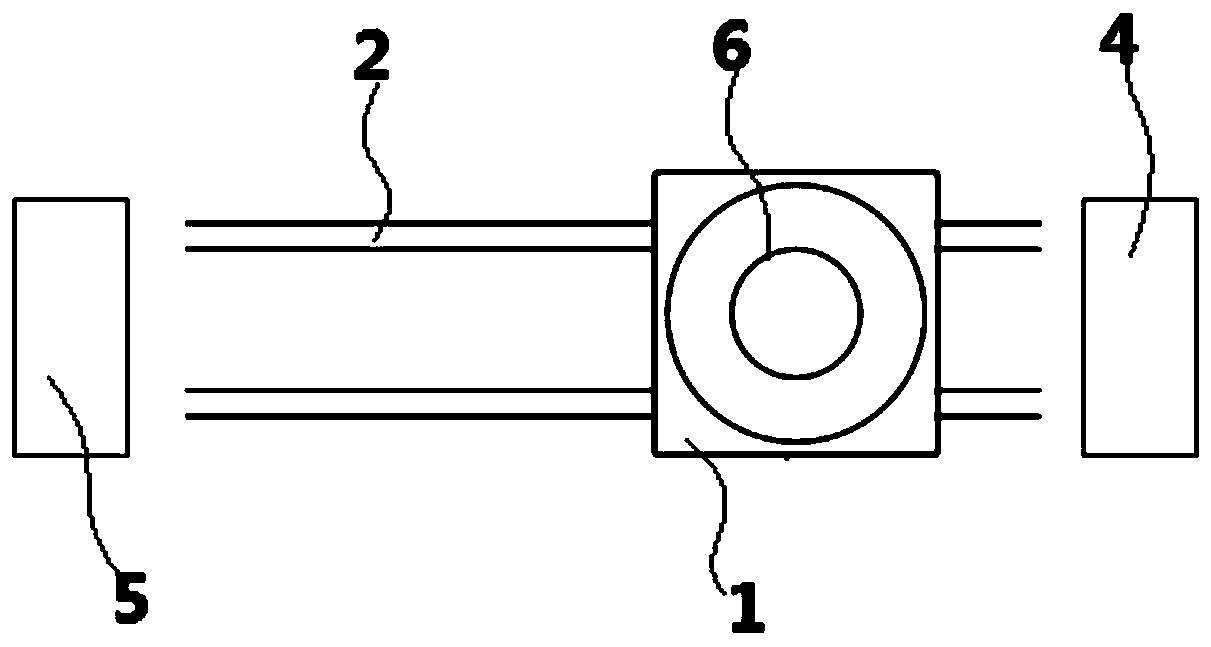

[0031] This embodiment discloses a rapid assembly device for an assembled wind power tower, which includes an assembly platform 1 and a transportation track 2.

[0032] See figure 1 The assembly type wind turbine tower quick assembling device is installed in a site, the site includes an assembly area 4 and a number of hoisting areas 5, and transportation rails 2 are set between the assembly area 4 and each hoisting area 5. The position of the assembly area 4 is fixed, and the suspension area 5 can be changed according to design requirements.

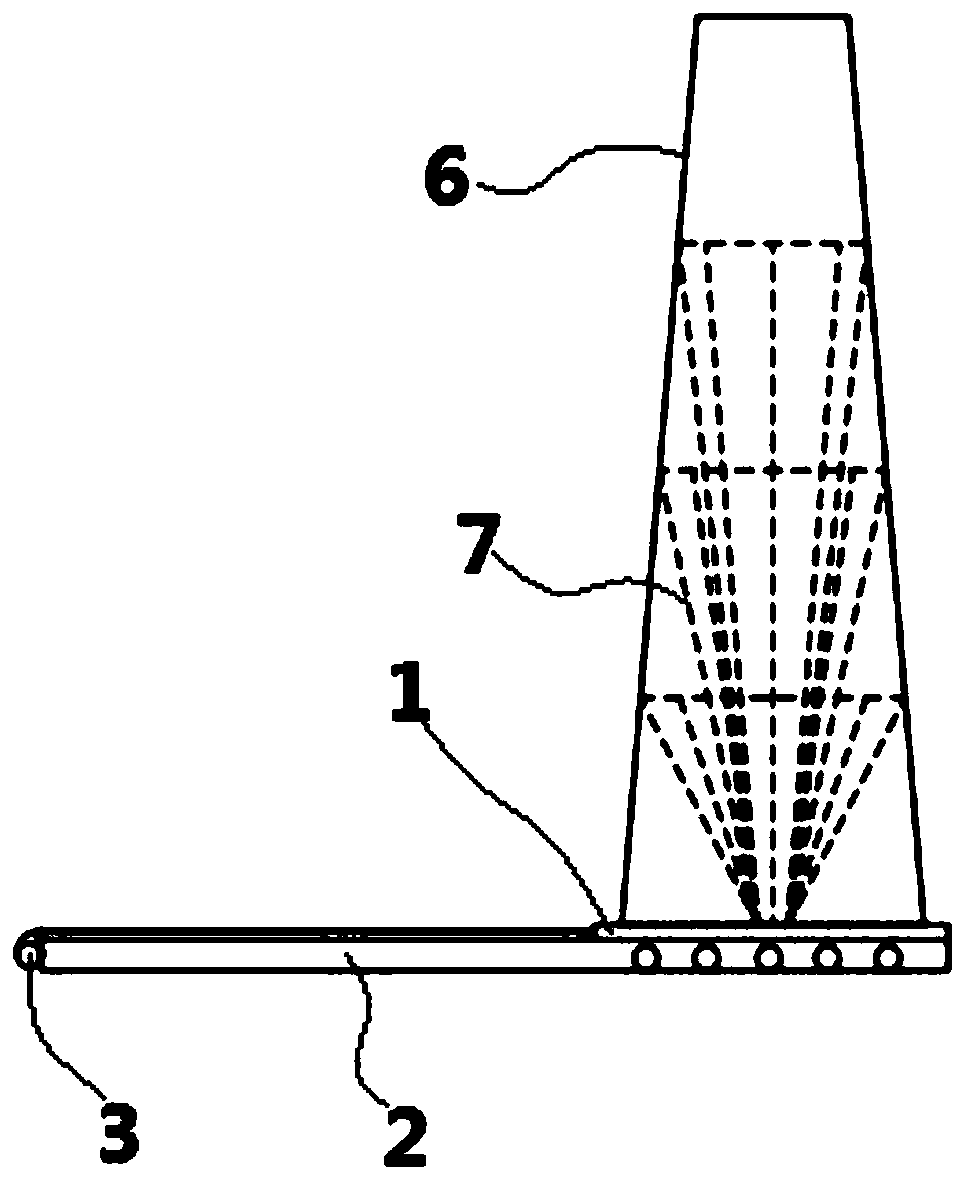

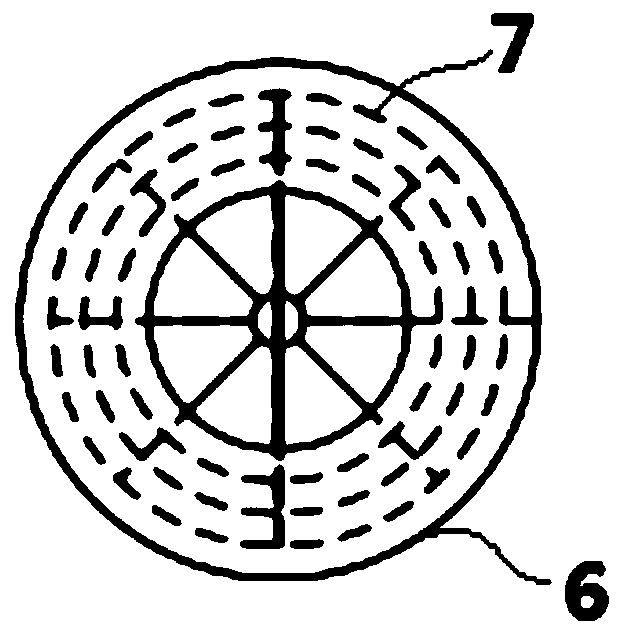

[0033] The assembly area 4 is provided with an assembling platform 1, and the tower 6 is assembled on the assembling platform 1, see figure 2 Or 3. A number of supports 7 are built in the tower 6 to fix the tower 6 on the assembling table 1.

[0034] See figure 2 , The tower 6 and the assembling table 1 slide along the transportation track 2 to each waiting area 5 under the influence of the hoist 3 and the cable. The assembly platform 1 can ...

Embodiment 2

[0036] This embodiment discloses a construction method of a fabricated wind turbine tower quick assembling device described in Embodiment 1, including the following steps:

[0037] 1) Assemble the tower tube 6 on the assembling table 1 in the assembly area 4.

[0038] 2) A number of supports 7 are set up inside the tower 6 to fix the tower 6 on the assembling platform 1.

[0039] 3) Determine the position and quantity of the suspension area 5 according to the design requirements, and lay the transportation track 2 between the assembly area 4 and each suspension area 5.

[0040] 4) Connect the assembly table 1 to the hoist 3 through cables.

[0041] 5) Start the hoist 3, and transport the tower 6 and the assembly platform 1 to the corresponding hoisting area 5.

[0042] 6) After the tower 6 is in place, all supports 7 are removed.

[0043] 7) Hoisting the tower 6 of the hoisting area 5.

[0044] Wherein, in step 6), there is also a step of detecting the tower 6, if the tower 6 is qualified,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com