Heat dissipation horn shell

A speaker and housing technology, applied in the field of sound amplification equipment, can solve the problems of not being able to meet the heat dissipation requirements, the heat dissipation mechanism destroying the airtightness of the shell, and the inability to ensure the efficient operation of the device, so as to achieve efficient physical heat conduction and heat dissipation, and ensure tight airtightness , Easy to disassemble and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

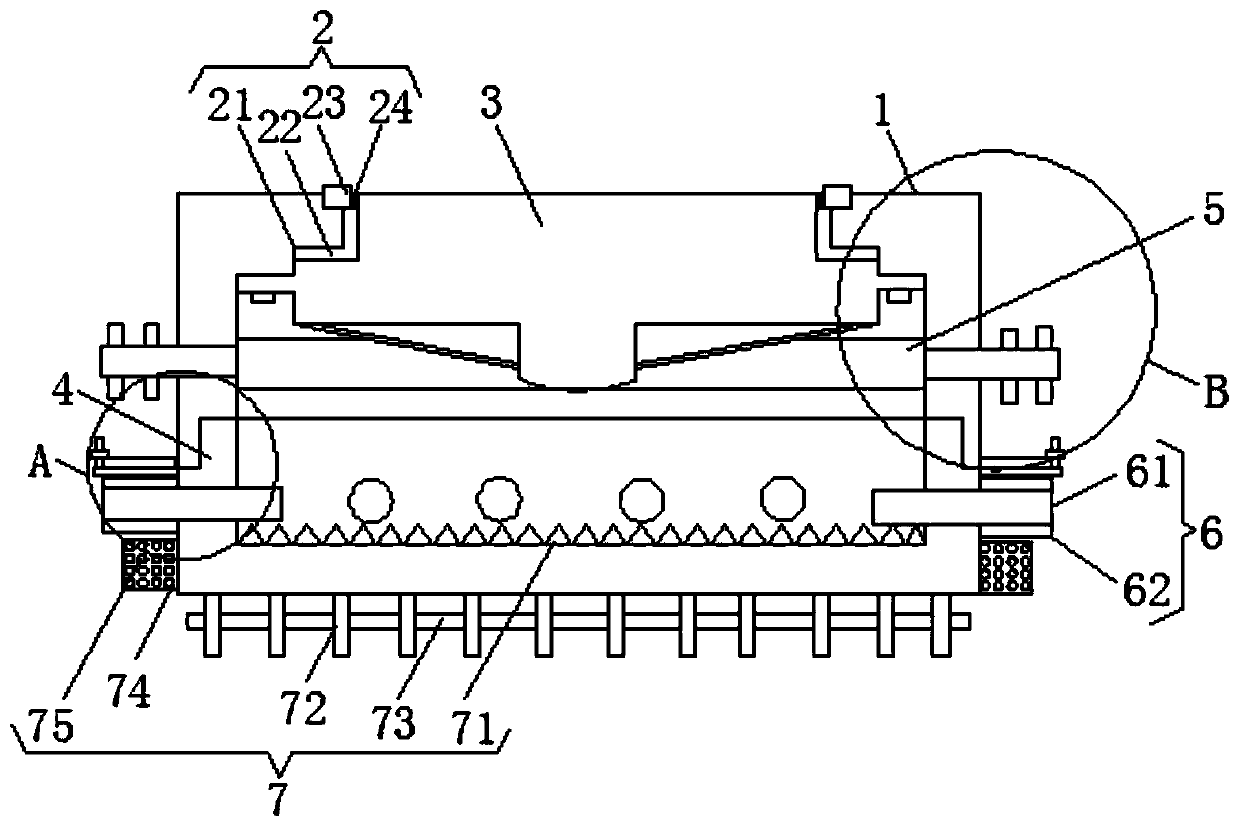

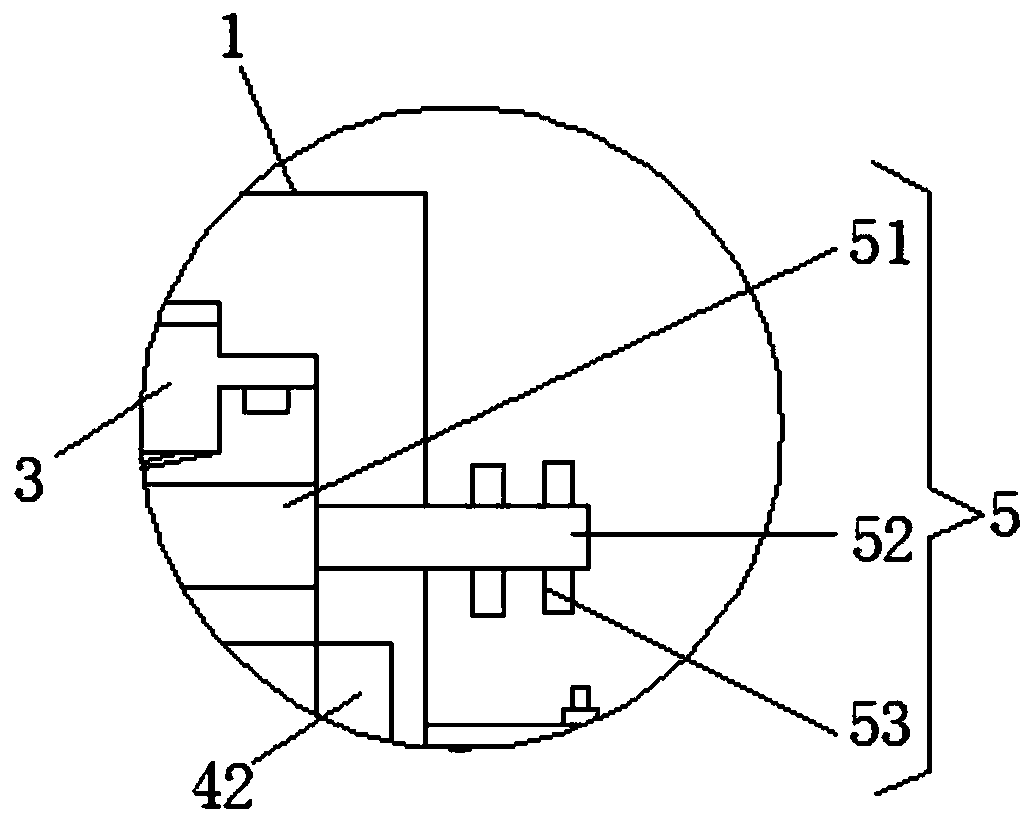

[0021] Embodiment 1: A heat dissipation horn housing, including a horn housing 1, a first connection and sealing mechanism 2, a second connection and sealing mechanism 4, a first heat dissipation mechanism 5, a second heat dissipation mechanism 6 and a third heat dissipation mechanism 7, the horn housing 1 The upper wall of the horn housing is provided with a mounting port, and the bottom end of the wall body of the horn housing 1 is an open structure. The first connecting and sealing mechanism 2 is arranged on the inner upper end of the horn housing 1, and is set corresponding to the mounting port on the upper wall of the horn housing 1, and the second The connecting and sealing mechanism 4 is correspondingly arranged at the opening of the bottom end of the wall of the horn housing 1, and the first heat dissipation mechanism 5 is uniformly arranged on the inner wall of the horn housing 1, and the first heat dissipation mechanism 5 includes a heat conduction fin 51, a heat condu...

Embodiment 2

[0024] The difference between this embodiment and Embodiment 1 is:

[0025] In this embodiment, the first connection and sealing mechanism 2 includes an inner edge groove 21, a sealing rubber pad 22, a threaded ring 23 and a sealing ring 24. The inner edge groove 21 is arranged at the inner upper end of the horn housing 1, and is connected to the upper wall of the horn housing 1. The installation opening of the horn housing 1 is correspondingly arranged, the sealing rubber pad 22 is correspondingly arranged on the inner wall of the inner edge groove 21, and is in corresponding contact with the horn body 3, the threaded ring 23 is threaded in the upper wall installation opening of the horn housing 1, and the sealing ring 24 is correspondingly arranged on the on the inner wall of the threaded ring 23 and is in corresponding contact with the horn body 3 .

[0026] Specifically, it is set in this way, after the installation of the horn body 3 and the horn housing 1, the horn body ...

Embodiment 3

[0028] The difference between this embodiment and Embodiment 1 is:

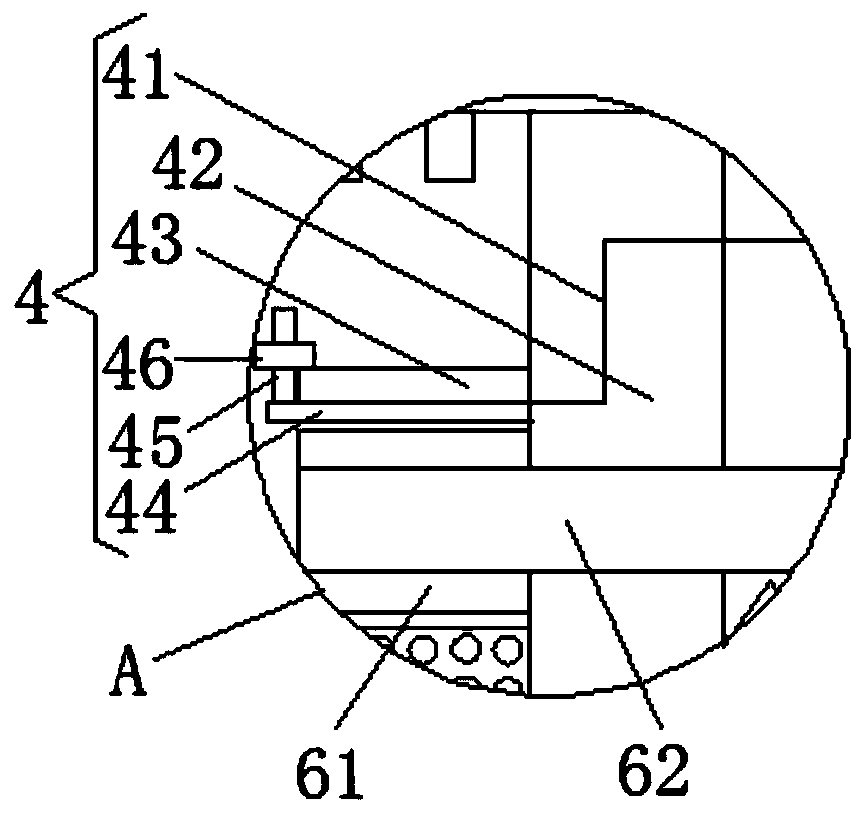

[0029]In this embodiment, the second connection and sealing mechanism 4 includes an internal thread groove 41, a cover 42, an extension plate 43, a butt plate 44, a threaded column 45 and a threaded pressure ring 46, and the internal thread groove 41 is correspondingly arranged on the wall of the horn housing 1 In the opening of the bottom end of the body, the cover 42 is threadedly connected with the internal thread groove 41, and is arranged correspondingly to the horn casing 1, the extension plate 43 is correspondingly arranged on the bottom end of the outer wall of the speaker casing 1, and the butt plate 44 is correspondingly arranged on the outer wall of the cover 42 On the upper end, the extension plate 43 and the butt plate 44 are correspondingly arranged, the threaded column 45 is symmetrically arranged at the edge of the upper wall of the butt plate 44, the threaded pressure ring 46 is threadedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com