Three-phase dry-type isolation transformer

A technology for isolating transformers and dry-type transformers, applied in the field of transformers, can solve problems such as damage to dry-type transformers, inconvenient maintenance of dry-type transformers, rigid collision between dry-type transformers and isolation boxes, etc., to prolong the service life and improve the firmness of placement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

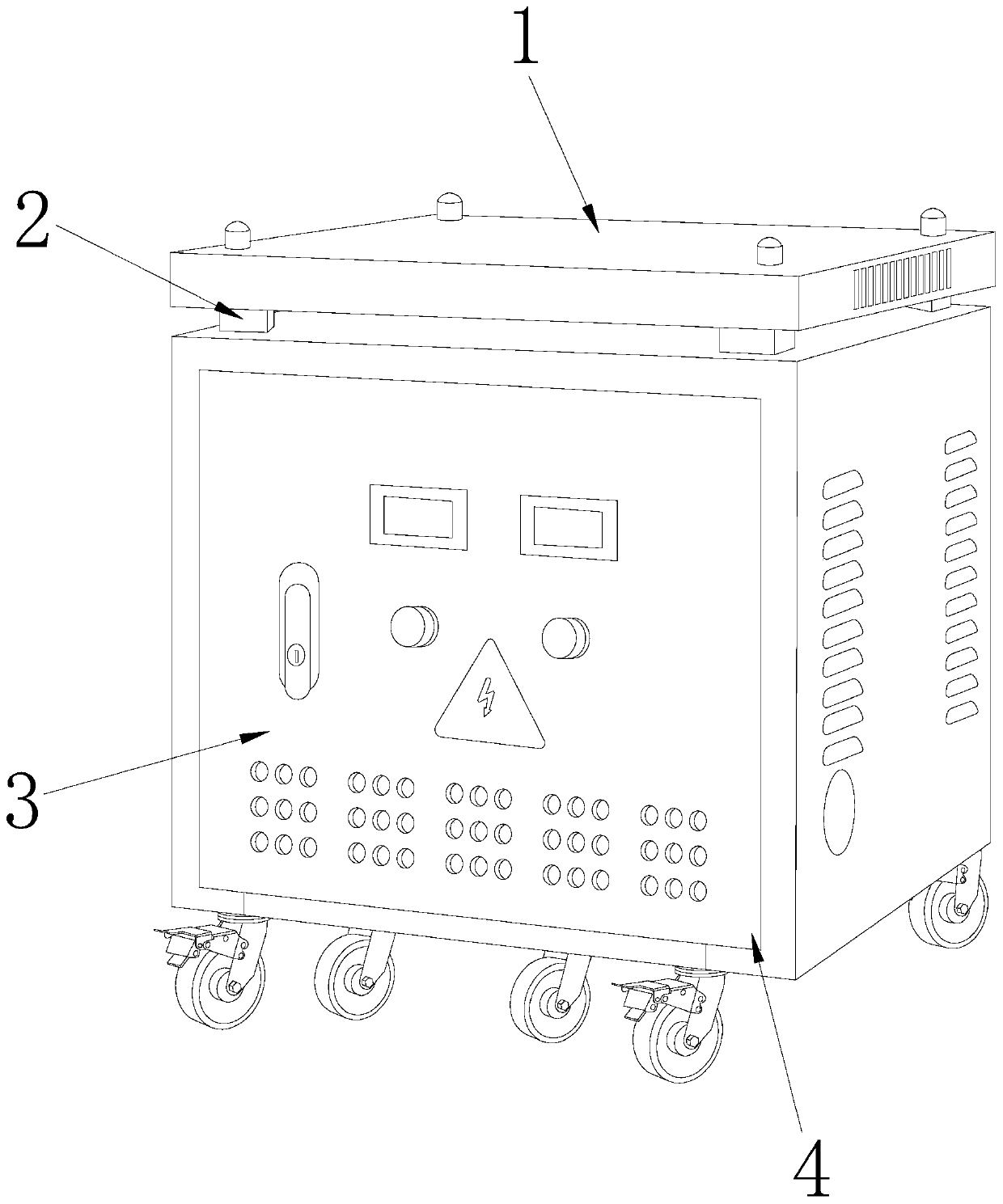

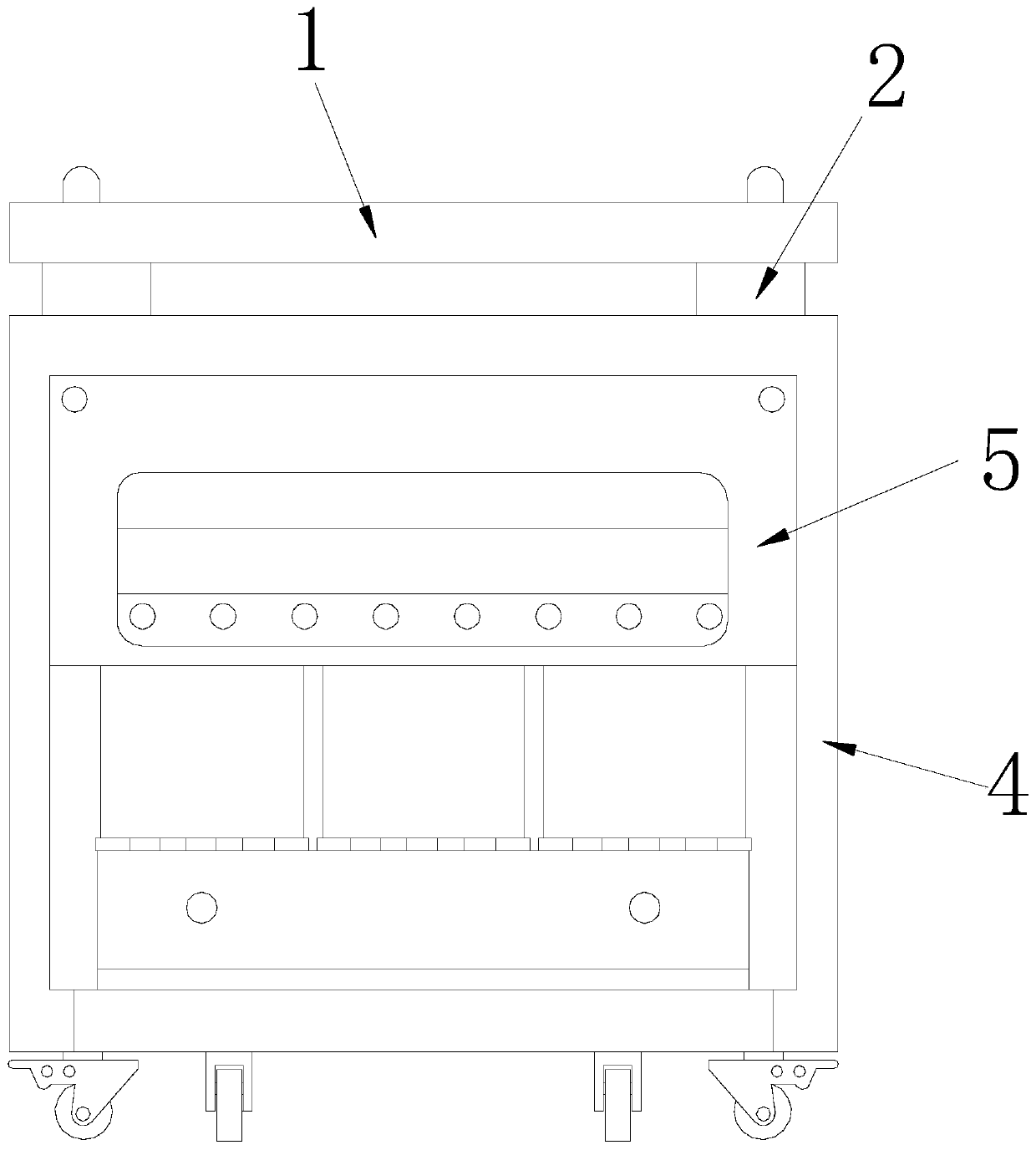

[0032] see figure 1 , the present invention provides a technical solution for a three-phase dry-type isolation transformer: please refer to Figure 1-8 , the present invention provides a technical solution of a three-phase dry-type isolation transformer: its structure includes a top plate 1, a connection block 2, a box door 3, an isolation box 4, and a dry-type transformer 5, and the top four corners of the isolation box 4 Both are connected to the top plate 1 through the connecting block 2, the outer hinge of the isolation box 4 is connected with the box door 3, and the isolation box 4 has a built-in dry-type transformer 5;

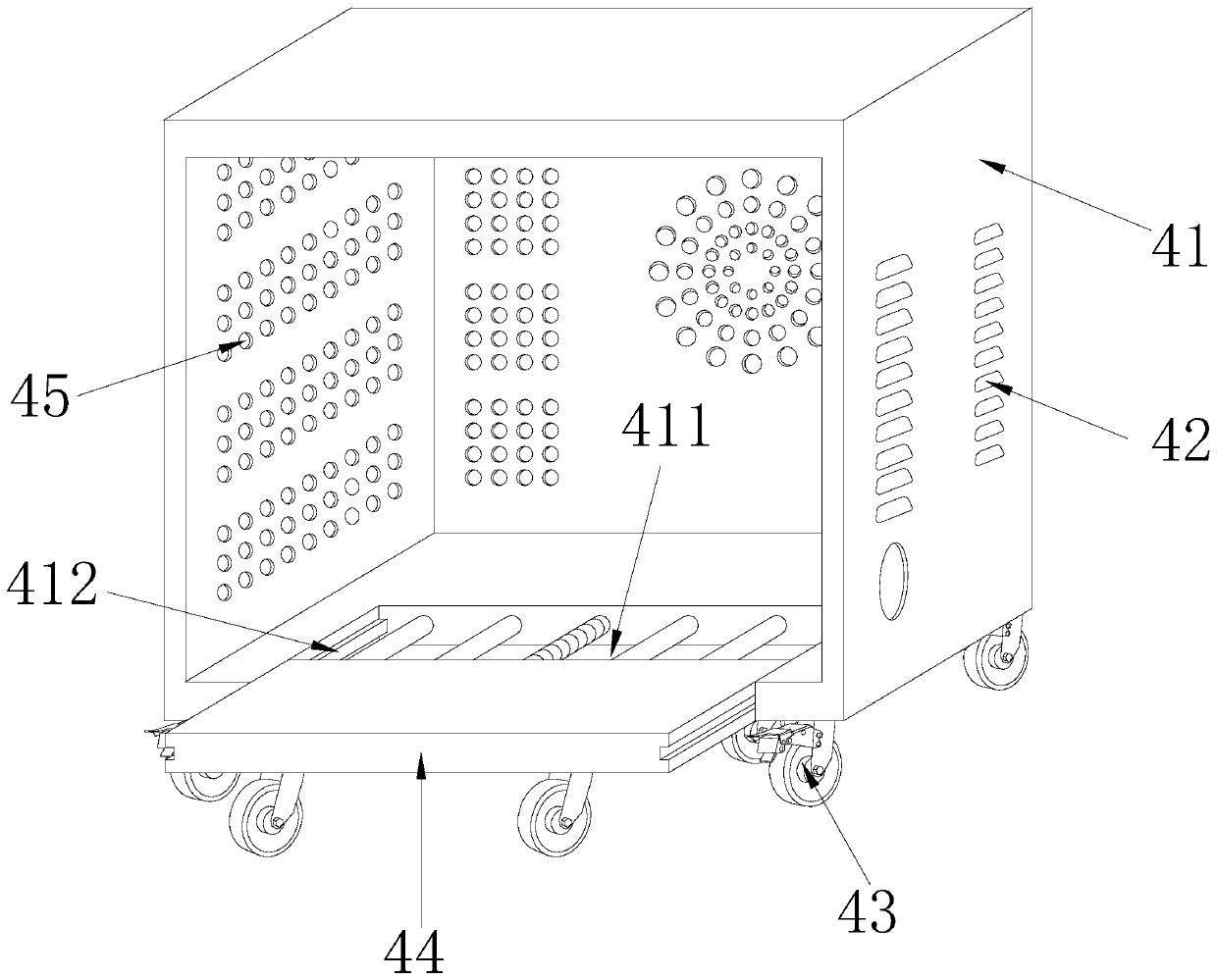

[0033] see Figure 2-3 , the isolation box 4 includes a box body 41, a heat dissipation grill 42, a universal wheel 43, a dry-type transformer placement device 44, and a heat dissipation hole 45. The four corners of the bottom of the box body 41 are mechanically connected with universal wheels. Wheel 43, one side of the box body 41 is evenly distribut...

Embodiment 2

[0039] see Figure 1-8 , the present invention provides a technical solution of a three-phase dry-type isolation transformer: its structure includes a top plate 1, a connection block 2, a box door 3, an isolation box 4, and a dry-type transformer 5, and the top four corners of the isolation box 4 Both are connected to the top plate 1 through the connecting block 2, the outer hinge of the isolation box 4 is connected with the box door 3, and the isolation box 4 has a built-in dry-type transformer 5;

[0040] The isolation box 4 includes a box body 41, a heat dissipation grill 42, universal wheels 43, a dry-type transformer placement device 44, and heat dissipation holes 45. The four corners of the bottom of the box body 41 are mechanically connected with universal wheels. 43. One side of the box body 41 is evenly distributed with heat dissipation holes 45, and the other side is evenly distributed with heat dissipation grilles 42. The bottom of the box body 41 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com