Device and method for testing thermal stability of optical axis of optical lens

An optical lens and thermal stability technology, which is applied in optical instrument testing, measuring devices, testing optical performance, etc., can solve the problems of large measurement error, thermal deformation of photodetector, and position change of imaging star points, and achieves easy testing process. , the effect of eliminating test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

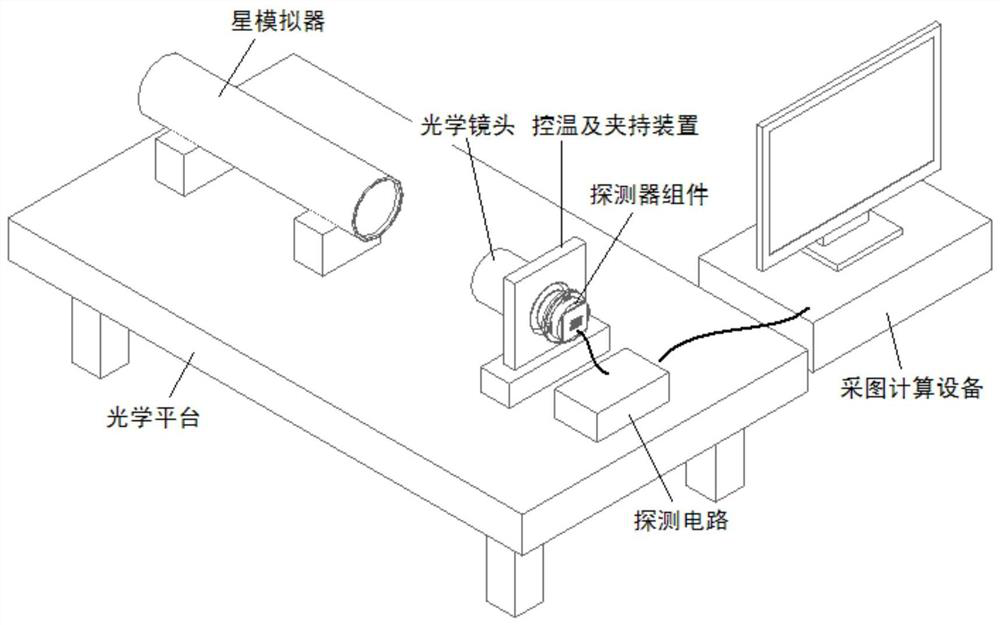

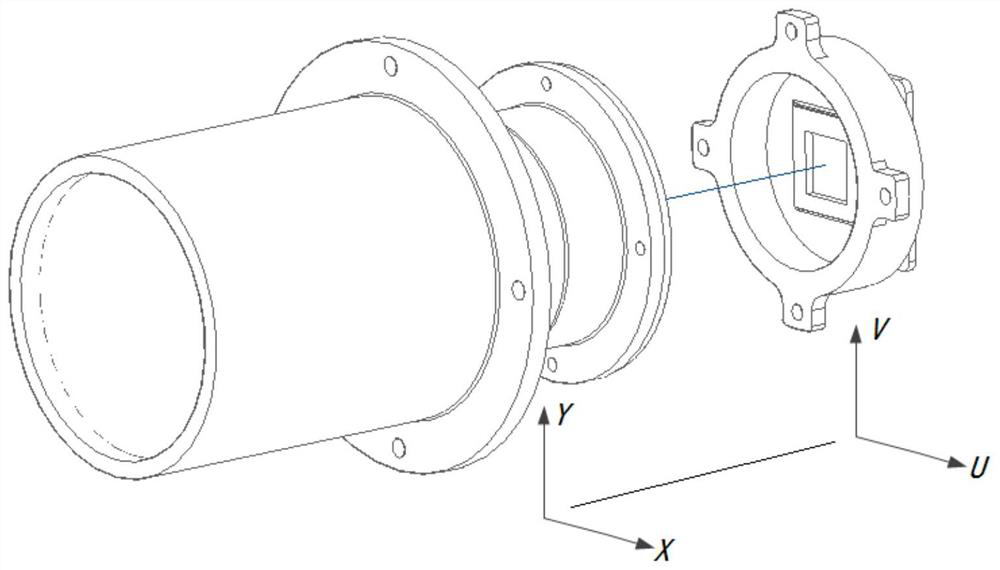

[0029] Such as figure 1 As shown, a test device for the thermal stability of the optical axis of an optical lens of the present invention includes an optical platform, a star simulator, an imaging assembly, a temperature control and clamping device, a detection circuit, and a drawing calculation device; the imaging assembly Including optical lens and detector components;

[0030] The optical platform provides a stable test environment as the basic support equipment for the test; the star simulator, imaging assembly, temperature control and clamping device are all placed on the optical platform during the test, and the star simulator and the optical lens are aligned in the axial direction and It is required that the light emitted by the star simulator can completely cover the entrance pupil of the optical lens; the star simulator simulates a star point at infinity as the detection target in the test; the light emitted by the star simulator forms an image on the detector compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com