Method for rapidly improving tenderness of fish meat of fugu

A technology for the tenderness of puffer fish meat and puffer fish meat is applied in food ultrasonic treatment, food science, etc., and can solve problems such as unfavorable fish meat texture and flavor characteristics, limited endogenous enzyme content, and slow tenderization speed. Achieve the effect of avoiding the change of flavor substances, high production efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

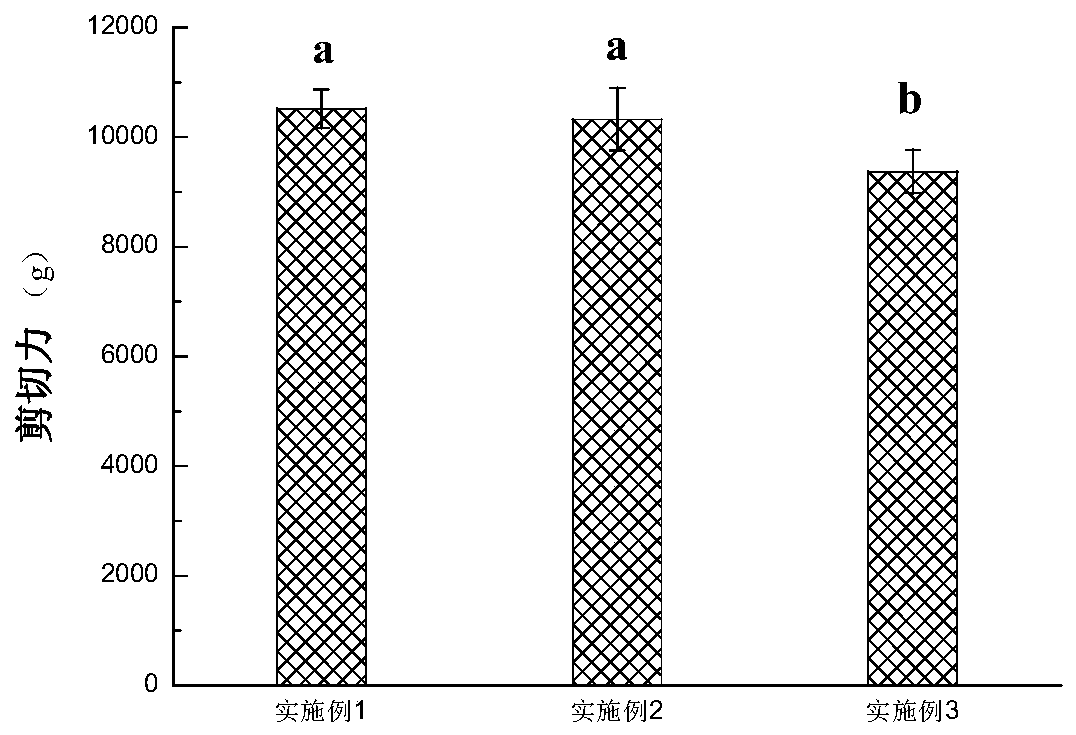

Embodiment 1

[0049] A method for rapidly improving the tenderness of puffer fish meat, the steps comprising:

[0050] S1. Take pufferfish meat and defrost it slowly, cut it into fish pieces with a length of 12cm and a width of 6cm, place them at 20-25°C until the central temperature is 20°C, and the fish flesh is soft; wherein, the total weight of the fish pieces is 224g ;

[0051] S2. Take the fish block with a central temperature of 20°C as described in step S1, put it in a packaging bag, add 200ml of the papain tenderizing solution, remove the air, and seal the package to obtain packaged fish meat; wherein, the papain tenderizing The solution is prepared by dissolving papain in water at 20°C, the concentration of papain is 0.09% by mass, and the packaging bag is made of transparent polyethylene with a thickness of 0.015mm;

[0052]S3. Take the packaged fish meat obtained in step S2, put it in an ultrasonic water bath, and perform ultrasonic treatment at 20° C., the ultrasonic power is ...

Embodiment 2

[0057] A method for rapidly improving the tenderness of puffer fish meat, the steps are:

[0058] S1. Take puffer fish meat for slow thawing, cut into fish pieces with a length of 12cm and a width of 6cm, and place them at 20-25°C until the center temperature is 20°C; wherein, the total weight of the puffer fish pieces is 241g ;

[0059] S2. Take food water at 20°C and configure 200mL of papain tenderizing solution with a mass fraction of 0.06%; wherein, the papain is produced by Jiangsu Xunyi Biotechnology Co., Ltd., and the enzyme activity is 100,000 U / g; The fish pieces with a central temperature of 20°C obtained in S1 are placed in a packaging bag, 200ml of the papain tenderizing solution is added, the air is removed, and the package is sealed to obtain packaged fish meat; wherein, the material of the packaging bag is transparent polyethylene, the thickness 0.015mm;

[0060] S3. Take the packaged fish meat obtained in step S2, place it in an ultrasonic water bath, and pe...

Embodiment 3

[0064] A method for rapidly improving the tenderness of puffer fish meat, comprising the following steps:

[0065] S1. Take puffer fish raw material fish meat and slow down and thaw, cut into fish pieces with a length of 12cm and a width of 6cm, and place them at 20-25°C until the center temperature is 20°C; wherein, the total weight of the puffer fish pieces 235g;

[0066] S2. Take food water at 20°C and configure 200mL of papain tenderizing solution with a mass fraction of 0.03%; wherein, the papain is produced by Jiangsu Xunyi Biotechnology Co., Ltd., and the enzyme activity is 100,000 U / g; The fish pieces with a central temperature of 20°C obtained in S1 are placed in a packaging bag, 200ml of the papain tenderizing solution is added, the air is removed, and the package is sealed to obtain packaged fish meat; wherein, the material of the packaging bag is transparent polyethylene, the thickness 0.015mm;

[0067] S3. Take the packaged fish meat obtained in step S2, place i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com