Laminated body including novolac resin as peeling layer

A phenolic novolac resin and laminate technology, which is applied in the direction of synthetic resin layered products, layered products, electric solid devices, etc., can solve the problems of large chip damage, heat generation, gas generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0148] (Preparation of Adhesive A for forming an adhesive layer)

[0149] Into a 600 mL stirring container dedicated to an autorotation and revolution mixer (manufactured by Shinky Co., Ltd., ARE-500), 95 g of vinyl group-containing MQ resin (manufactured by Wakka Chemi Co., Ltd.) as a polysiloxane (a1) and 95 g of a diluting solvent were added. 93.4 g of p-menthane (manufactured by Japan Terpen Chemical Co., Ltd.) and 0.41 g of 1,1-diphenyl-2-propen-1-ol (manufactured by Tokyo Chemical Industry Co., Ltd.) ) Shinki, ARE-500) was stirred for 5 minutes. To the obtained mixture were added SiH group-containing linear polydimethylsiloxane (manufactured by Wakka Chemical Co., Ltd.) having a viscosity of 100 mPa·s as polysiloxane (a2), 29.5 g of vinyl-group-containing linear polydimethylsiloxane (manufactured by Wakka Chemical Co., Ltd.) with a viscosity of 200 mPa·s, and a viscosity of 1,000,000 mm as component (B) 2 0.41 g of polyorganosiloxane (manufactured by Wakka-chemi Co., L...

Synthetic example 1

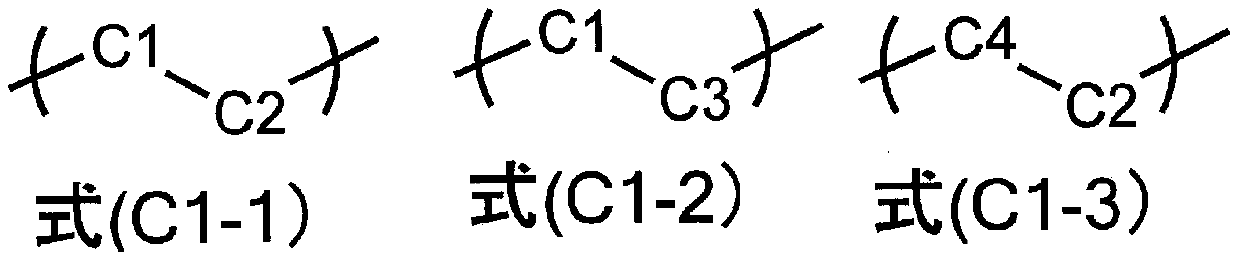

[0152] Into a 100 mL four-necked flask under nitrogen, 8 g of carbazole (manufactured by Tokyo Chemical Industry Co., Ltd.), 7.55 g of 1-naphthaldehyde (manufactured by Tokyo Chemical Industry Co., Ltd.), and p-toluenesulfonic acid monohydrate (manufactured by Kanto Chemical Industry Co., Ltd.) were added. Co., Ltd.), 8 g of 1,4-dioxane (manufactured by Kanto Chemical Co., Ltd.) was added and stirred, and the temperature was raised to 100° C. to dissolve them and start polymerization. After 4 hours, it was left to cool to 60° C., then diluted with 40 g of chloroform (manufactured by Kanto Chemical Co., Ltd.), and reprecipitated in 200 g of methanol. The obtained precipitate was filtered and dried in a decompression dryer at 60°C for 10 hours, and then at 120°C for 24 hours to obtain the target polymer (having the structural unit of formula (C1-1-1-1) polymer). Hereinafter abbreviated as PCzNA) 10.03g.

[0153] PCzNA had a weight average molecular weight Mw of 2600 in terms o...

Synthetic example 2

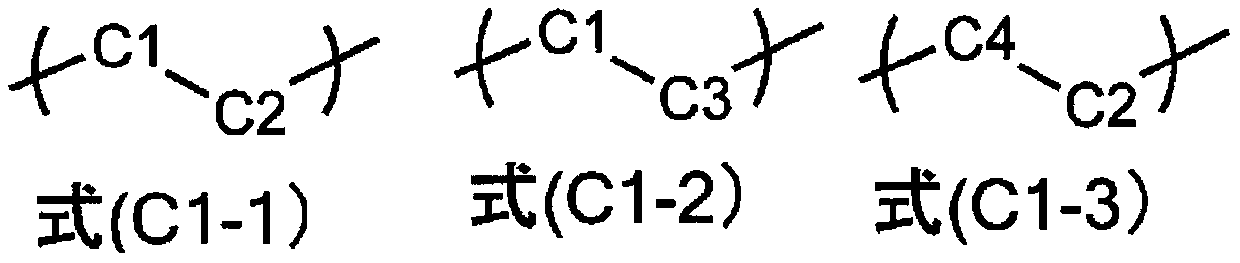

[0155] 15.00 g of 4,4'-biphenol (manufactured by Tokyo Chemical Industry Co., Ltd.), 18.55 g of 1-pyrylene formaldehyde (manufactured by Aldrich Co., Ltd.) and p-toluenesulfonic acid monohydrate were added to a 300 mL four-necked flask under nitrogen gas (Tokyo Chemical Industry Co., Ltd. product) 33.210g, Furthermore, propylene glycol monomethyl ether (Kanto Chemical Co., Ltd. product) 44.93g was added, and it heated up to 120 degreeC with stirring, these were melt|dissolved, and polymerization started. After 24 hours, it was left to cool to room temperature, and reprecipitated in 1800 g of methanol. The obtained precipitate was filtered and dried in a vacuum dryer at 50°C for 10 hours to obtain the target polymer (a polymer having a structural unit of the formula (C1-3-1-4). Hereinafter, it will be abbreviated as PBPPCA. ) 19.08g. The weight average molecular weight Mw in terms of polystyrene measured by PBPPCA was 2,200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com