A kind of ultra-high-strength tempered eh690 extra-thick steel plate and its manufacturing method

An extra-thick steel plate and ultra-high technology, which is applied in the field of quenched and tempered EH690 extra-thick steel plate and its manufacturing, can solve the problems that cannot meet the strength index requirements of large-thickness ultra-high-strength steel plates, cannot meet the steel index requirements for offshore platforms, and cannot meet the ultra-high Emphasis on the demand for high-quality steel plates and other issues, to achieve the effect of high control of morphology and grain size, good uniformity of structure and performance, and improvement of steel purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

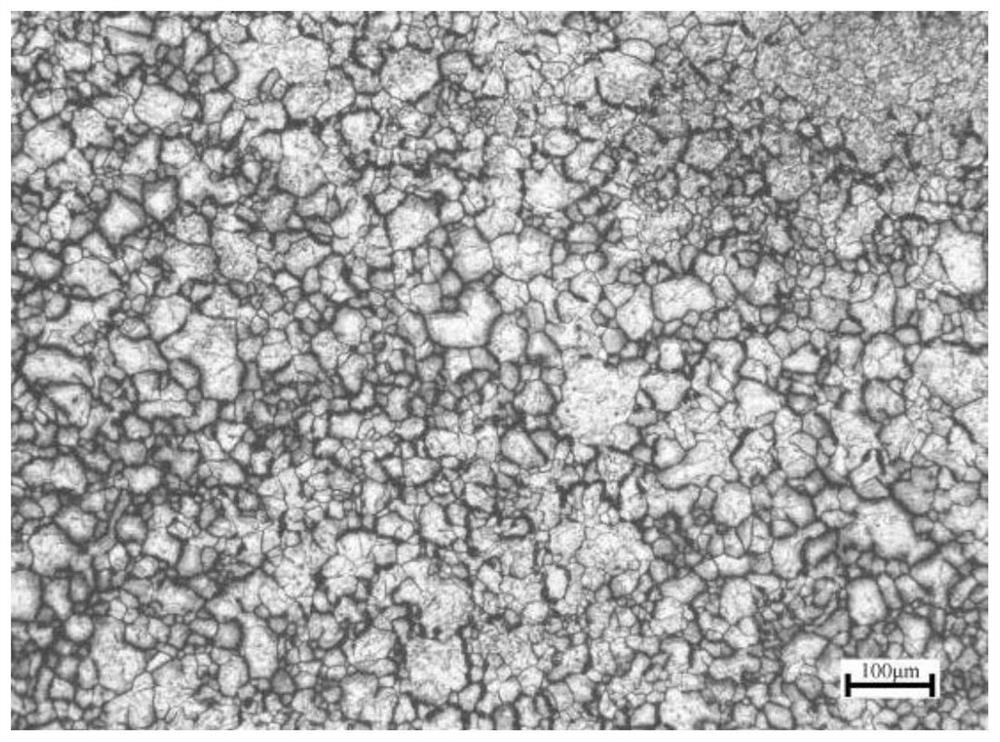

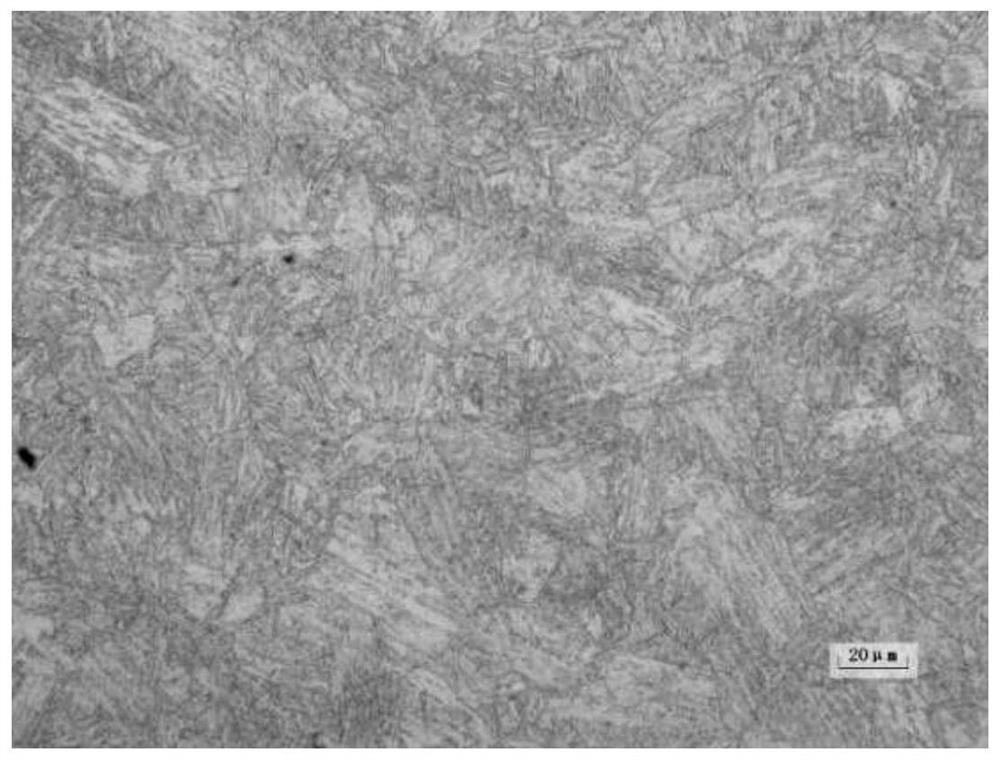

Image

Examples

Embodiment Construction

[0039] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

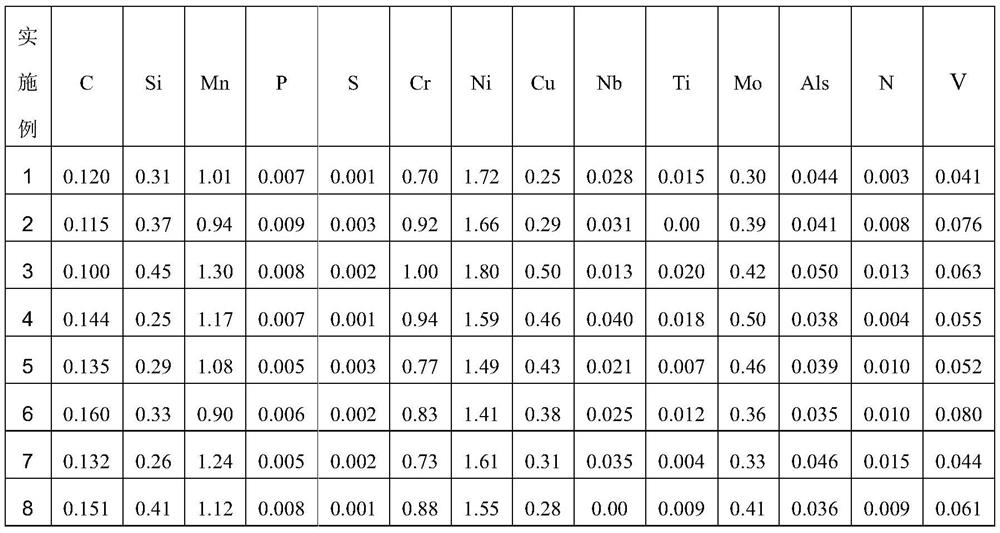

[0040] Table 1 is the chemical composition of the steel of the embodiment of the present invention; Table 2 is the rolling method of the steel of the embodiment of the present invention; Table 3 is the heat treatment process of the steel of the embodiment of the present invention; Table 4 is the mechanical properties of the steel of the embodiment of the present invention.

[0041] Table 1 The chemical composition wt% of the steel plate of the embodiment of the present invention

[0042]

[0043] Table 2 steel rolling method of the embodiment of the present invention

[0044]

[0045] The heat treatment method of table 3 embodiment steel of the present invention

[0046]

[0047] Table 4 steel tensile and impact prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com