BOPP adhesive tape winding device and using method thereof

A technology of winding device and adhesive tape, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., which can solve the problems of inconvenient use, inconvenient speed adjustment, troublesome operation, etc., and achieve convenient use, firm fixation, and bonding solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

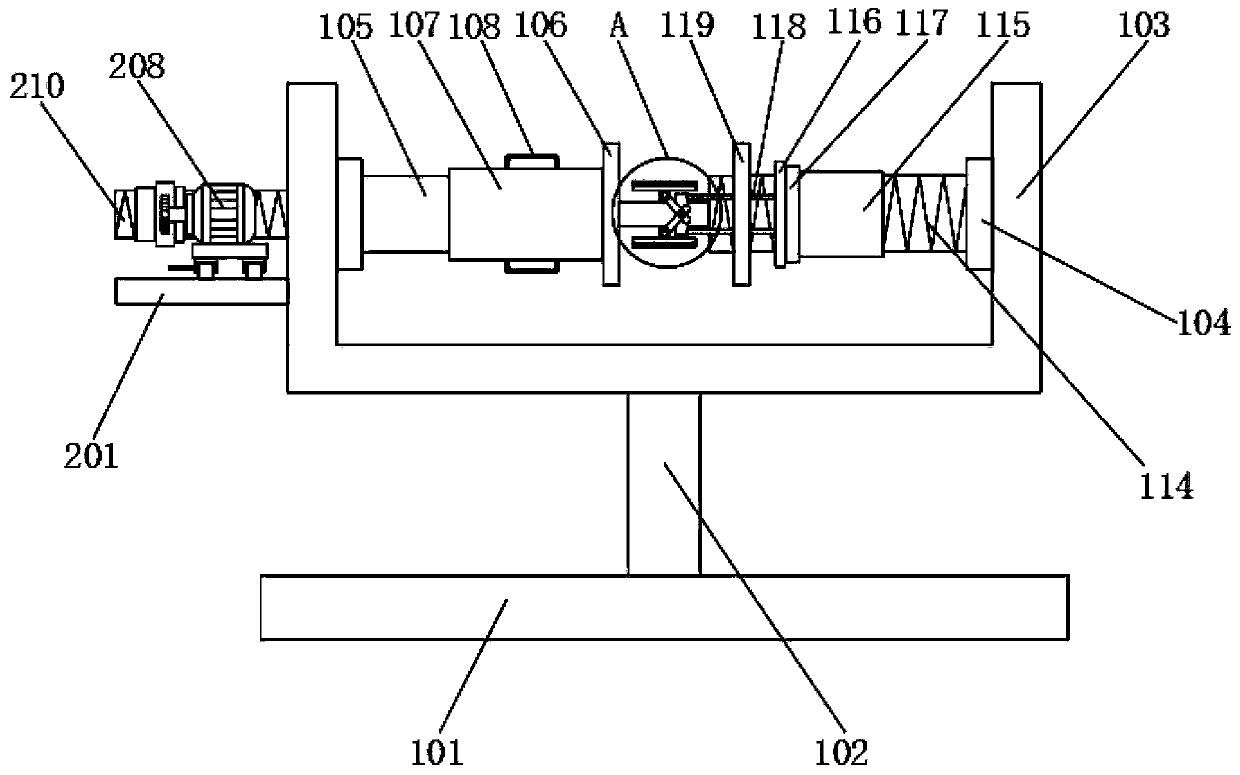

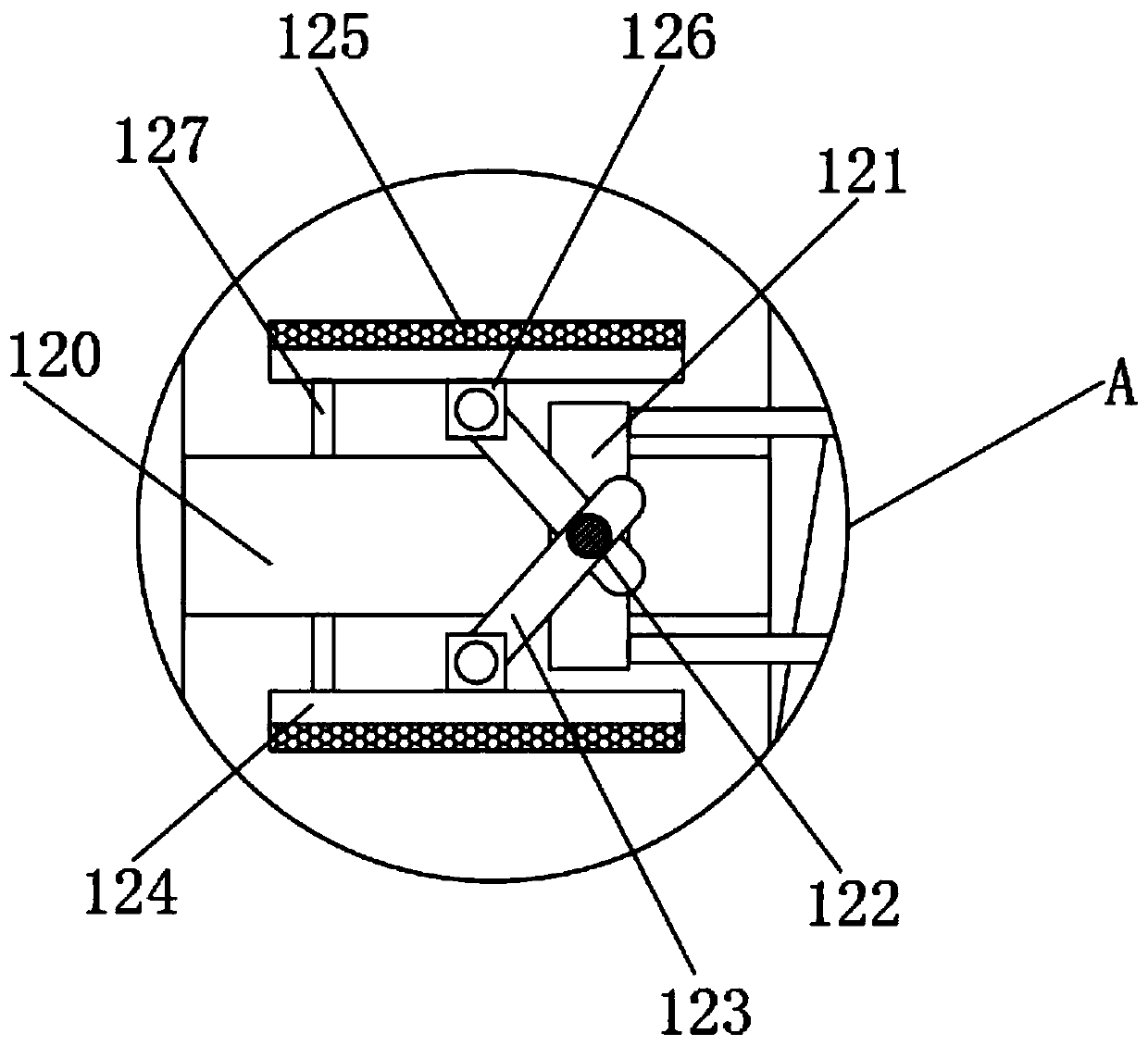

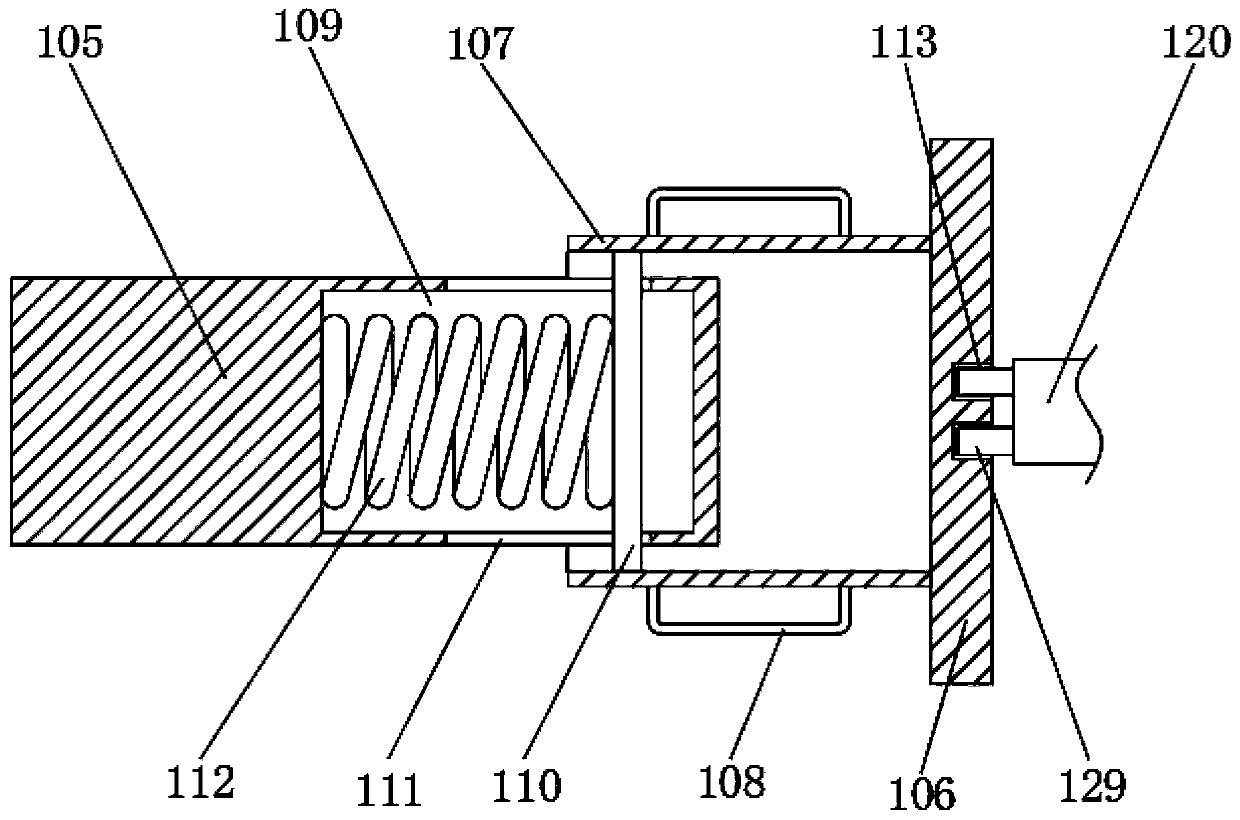

[0045] see Figure 1-2 , a BOPP tape winding device, comprising a device base 101, a support column 102 is fixedly installed on the top outer wall of the device base 101, a U-shaped base 103 is fixedly installed on the top of the support column 102, and the inner walls of the left and right sides of the U-shaped base 103 The first bearing 104 is fixedly installed on the top, the inner wall of the inner ring of the first bearing 104 on the left inner wall is fixedly connected with the first support rod 105, and the inner wall of the inner ring of the first bearing 104 on the right inner wall is fixedly connected with the second Support rod 114, the first adjusting cylinder 107 is installed on the outer wall of the first supporting rod 105, the right end of the first adjusting cylinder 107 is fixedly connected with the first splint 106, the inside of the first supporting rod 105 is provided with an adjusting groove 109, the second A riser 110 is fixedly connected to the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com