Four-link type bin arch breaking system and method and application of four-link type bin arch breaking method

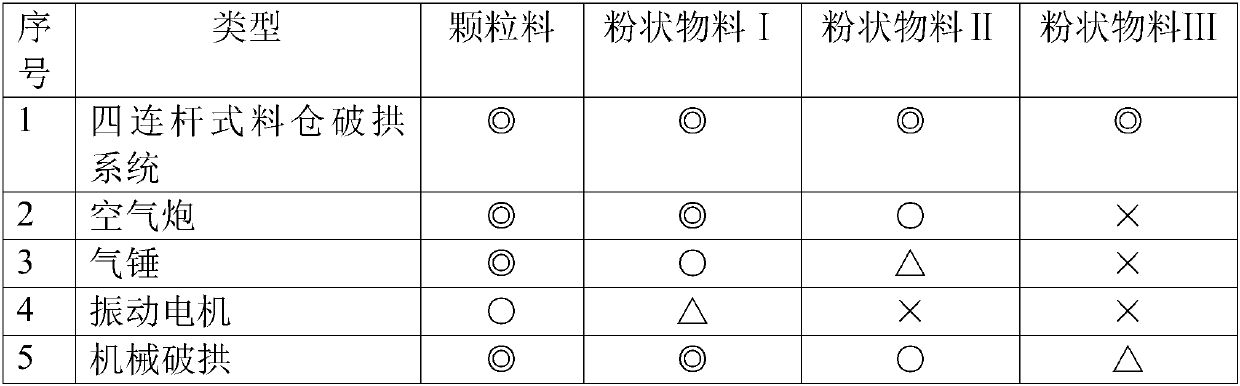

A four-bar linkage and silo technology, applied in the field of material conveying equipment, can solve the problems of reduced energy efficiency and reliability, narrow adaptability, high manufacturing and maintenance costs, and achieve the effect of ensuring reliability, realizing simplicity, and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

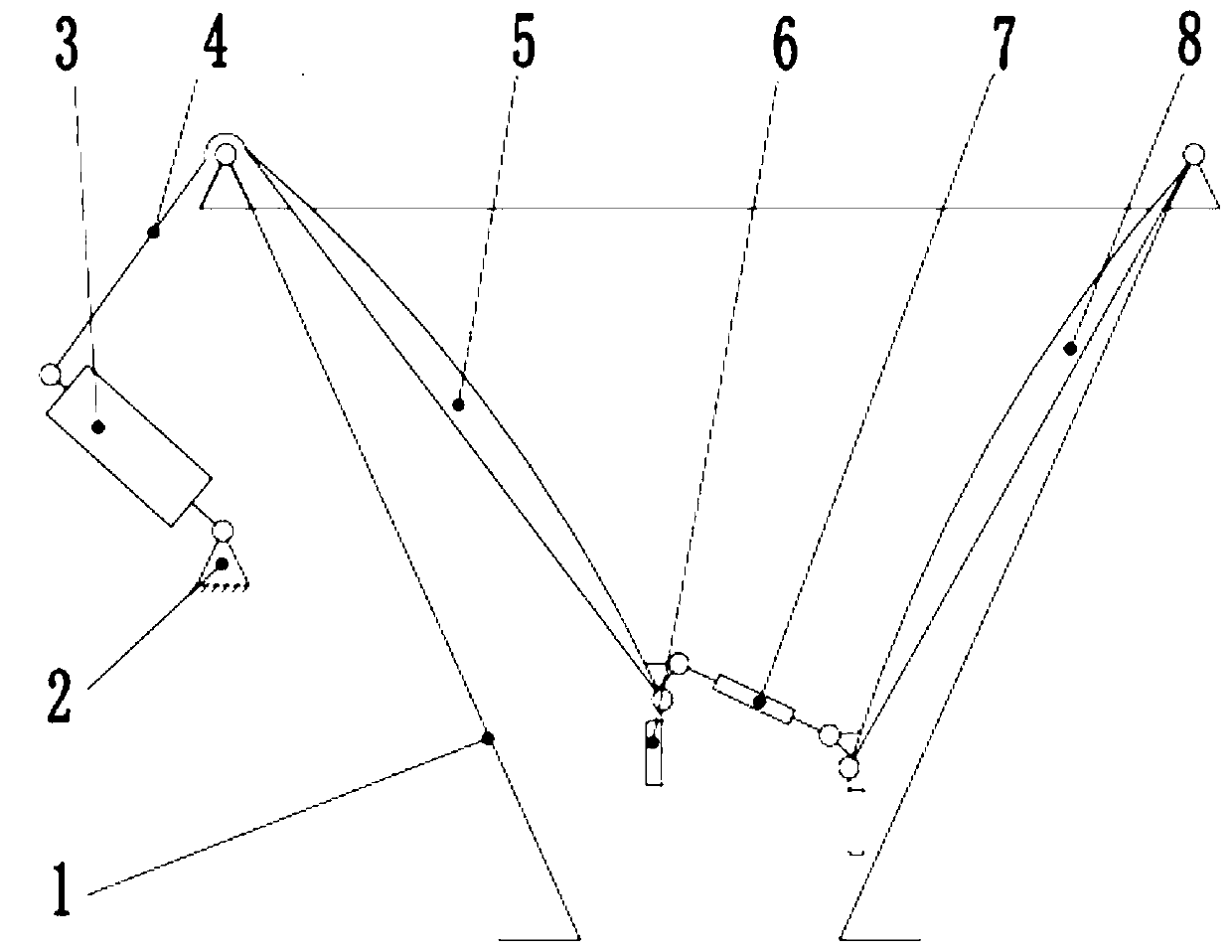

[0046] Aiming at the problems existing in the prior art, the present invention provides a four-link silo arch breaking device, an arch breaking method and its application. The present invention will be described in detail below with reference to the accompanying drawings.

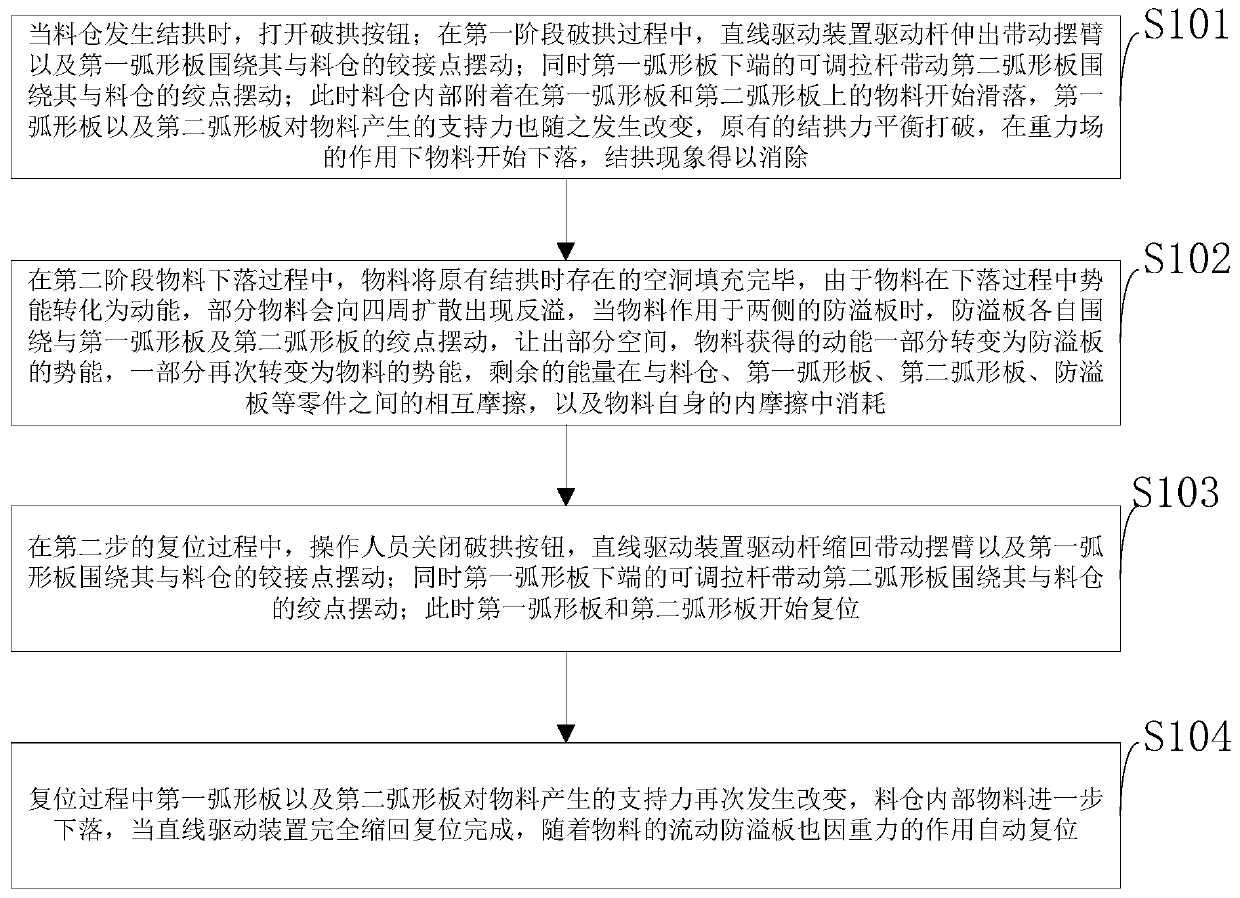

[0047] Such as figure 1 As shown, the method for breaking the arch of the four-link silo provided by the embodiment of the present invention specifically includes the following steps:

[0048] S101: When arching occurs in the silo, turn on the arch breaking button; during the first stage of arch breaking, the drive rod of the linear drive device extends to drive the swing arm and the first arc plate to swing around the hinge point with the silo; At the same time, the adjustable pull rod at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com