Pulse heat sealing type bag making machine

A heat-sealing, bag-making machine technology, used in bag-making operations, flexible container manufacturing, paper/cardboard containers, etc., can solve the problems of thermal insulation cloth being susceptible to heat aging, worker burns, and bag-making machine structure extension, etc. Achieve the effect of guaranteeing the pass rate and traceability, fast and stable sealing action, and reducing the structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

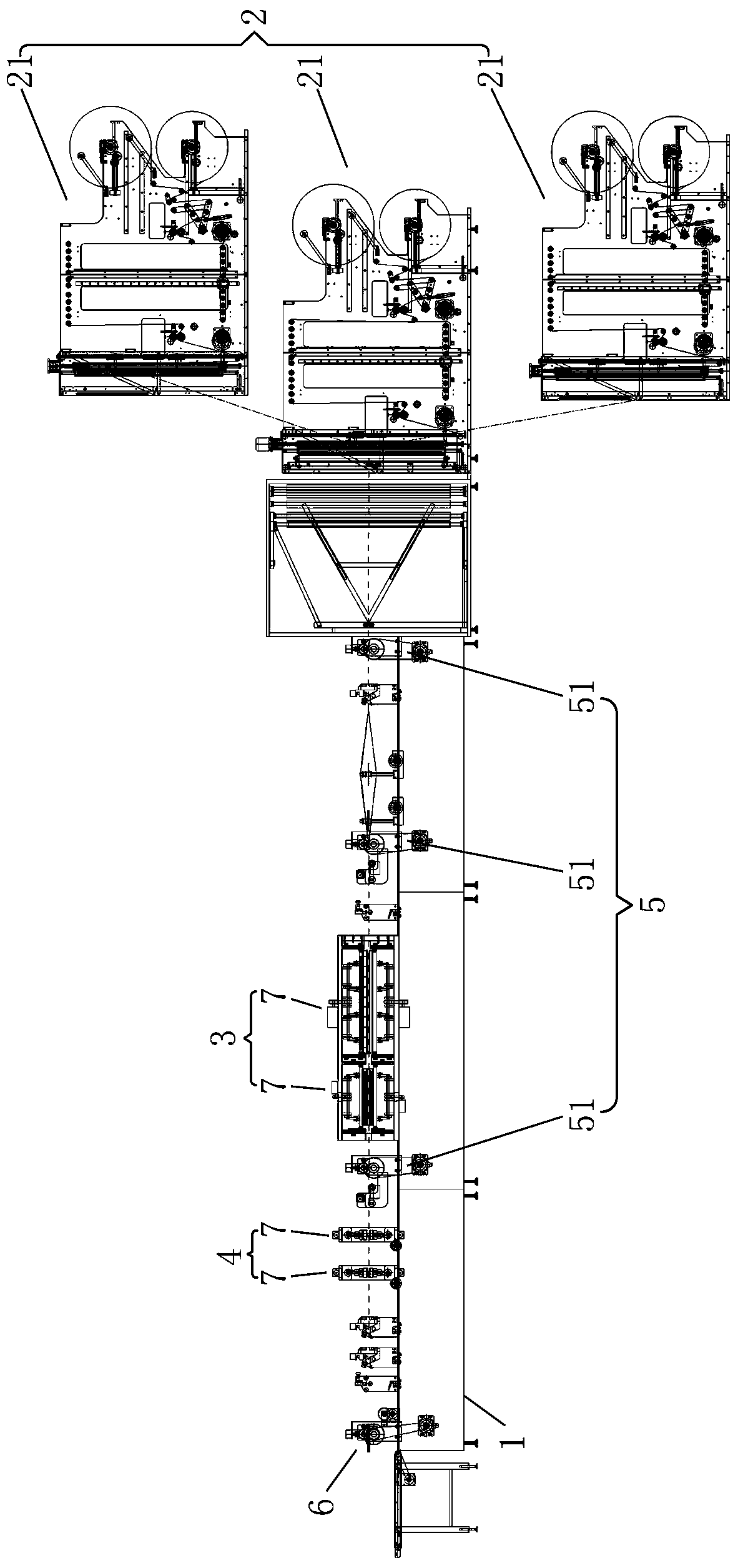

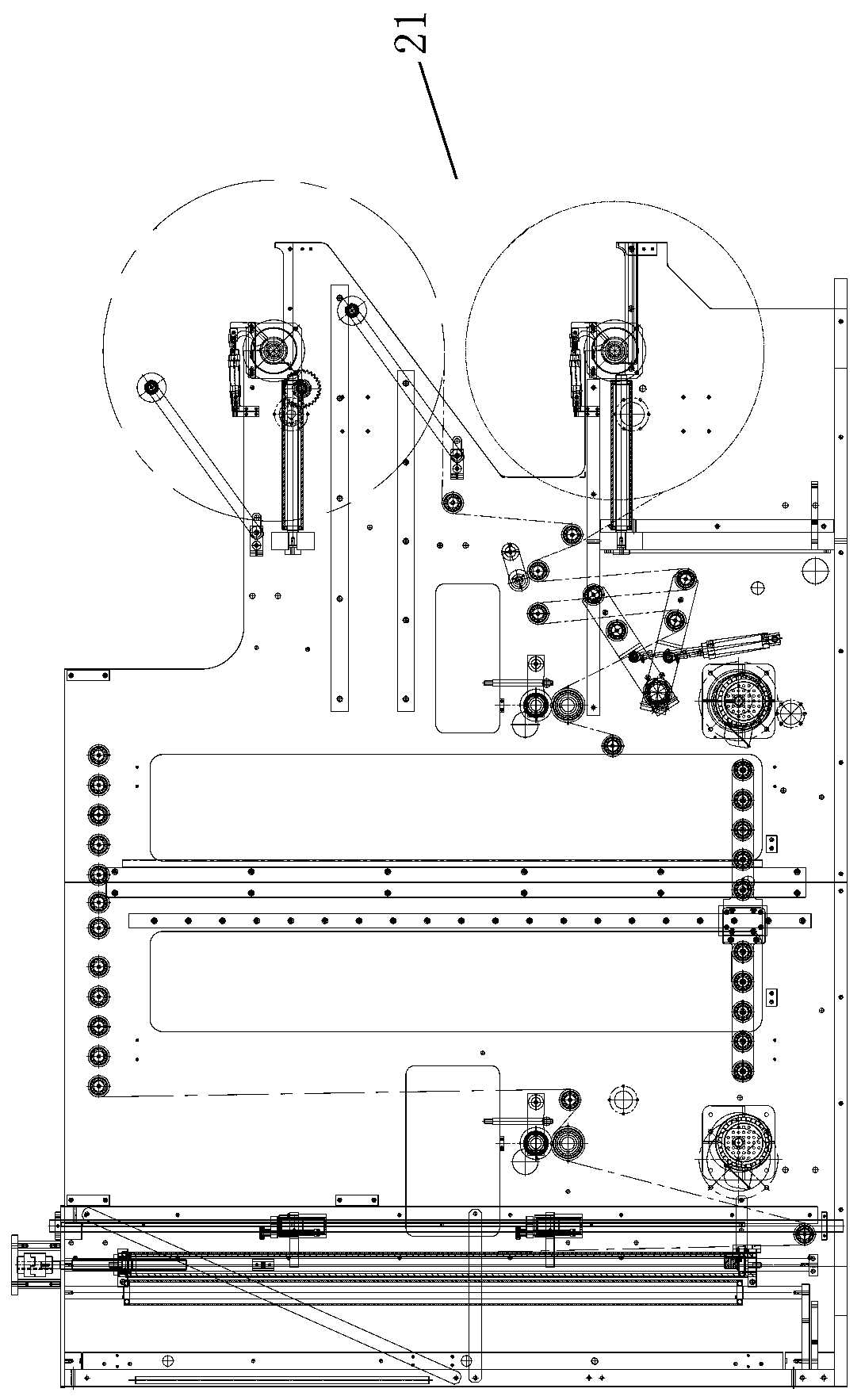

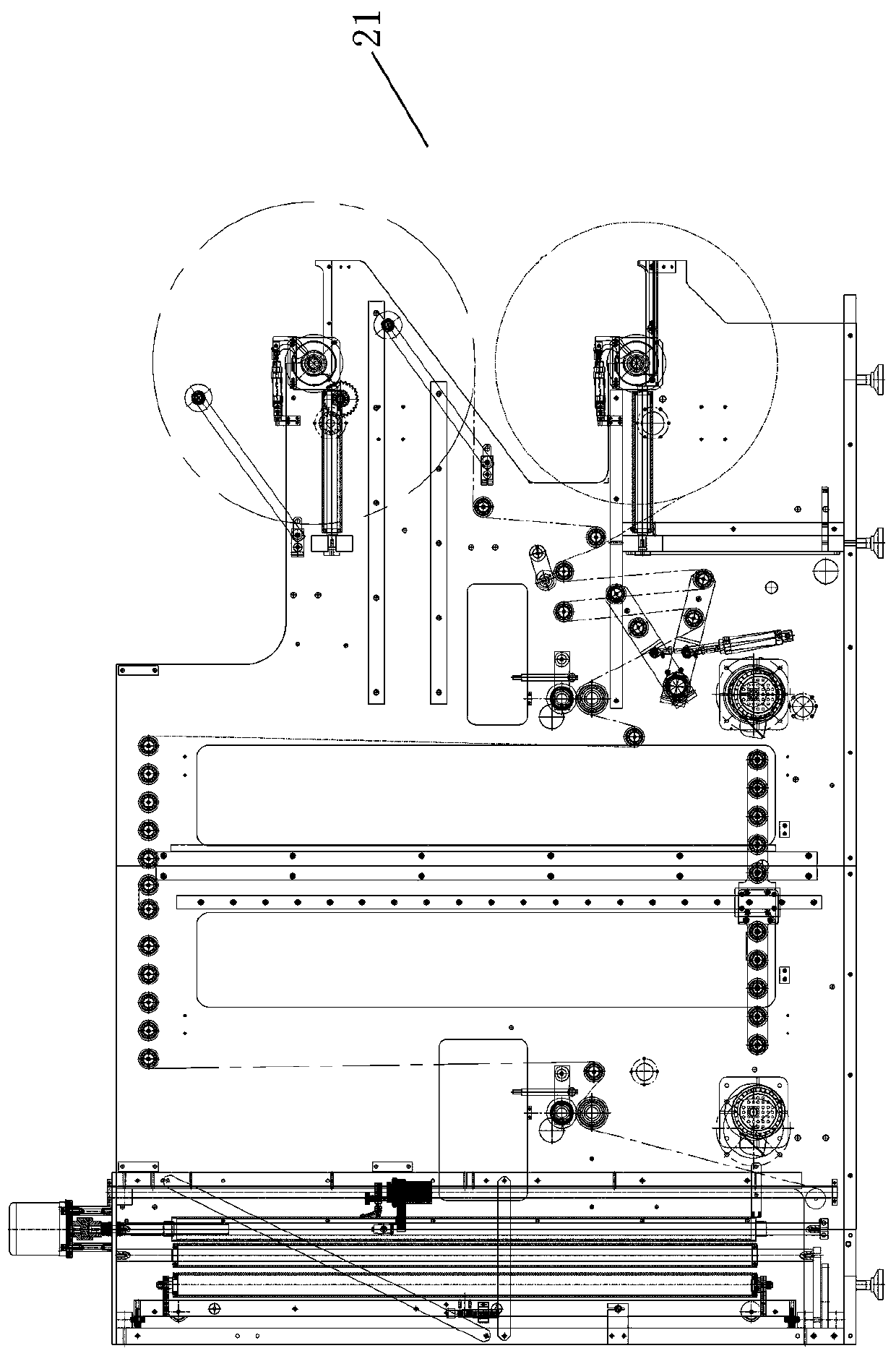

[0041] Such as Figure 1-11 As shown, the pulse heat-sealing bag making machine in this preferred embodiment includes a frame 1, a control device, an unwinding mechanism 2, a longitudinal sealing mechanism 3, a horizontal sealing mechanism 4, a traction mechanism 5, and a traction bag cutting mechanism 6, The unwinding mechanism 2, the longitudinal sealing mechanism 3, the horizontal sealing mechanism 4, the traction mechanism 5, and the traction bag cutting mechanism 6 are respectively installed on the frame 1 and they are distributed sequentially along the longitudinal direction of the frame 1 from back to front, and the control device is installed on on rack 1. In this embodiment, the unwinding mechanism 2 includes three unwinding devices 21, and the three unwinding devices 21 transport the film respectively. The traction mechanism 5 includes a plurality of traction devices 51 , and the plurality of traction devices 51 are distributed sequentially along the moving directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com