Automatic edge collector

An automatic and collector technology, applied in metal processing, conveying filamentous materials, thin material processing, etc., can solve the problem of difficult on-site control of side materials, achieve convenient and fast fixing and loosening, no noise, simple and fast operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

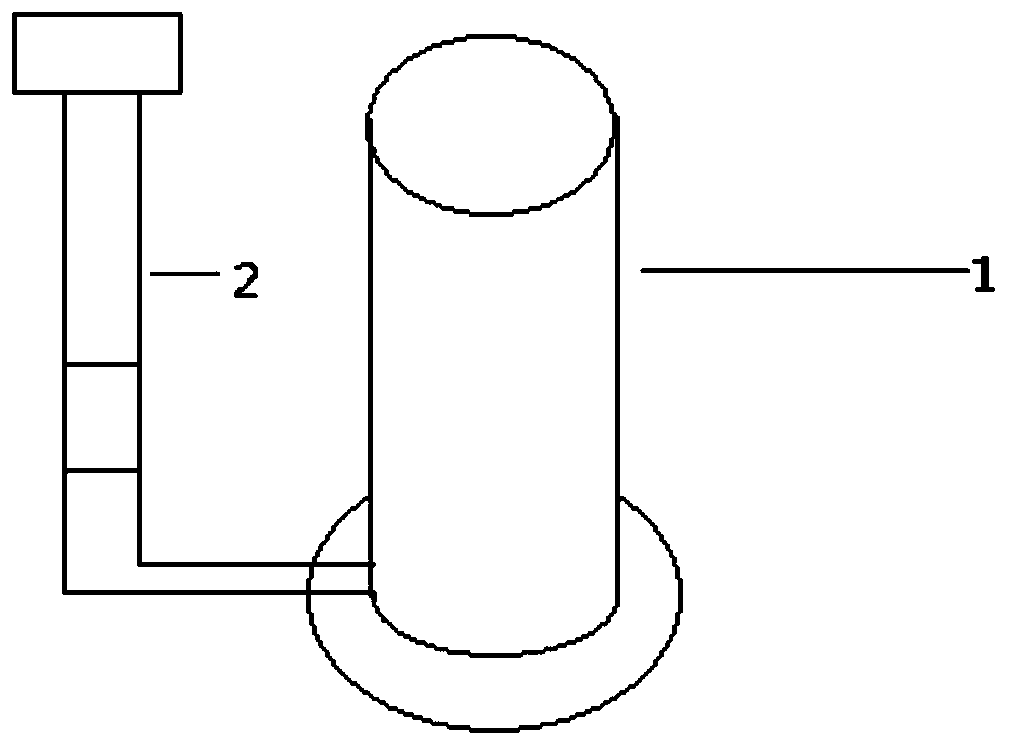

[0012] like figure 1 As shown, the present invention provides an automatic edge collector, comprising an edge collector 1 and a rotational speed console 2, the rotational speed console 2 controls the rotation of the edge collector 1, and the edge collector 1 is provided with a fixed The clipping slot, the trimming produced edge strip is stuck on the clipping slot, and the strip collector 1 rotates under the drive of the rotational speed console 2 so that the strip is wound on the strip collector 1 .

[0013] Specifically, the rotational speed conso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com