Self-adaptive and compliant manipulator for internal support operation of fragile thin-walled cylindrical inner wall workpiece

A thin-walled cylindrical, self-adaptive technology, applied in the field of robotics, can solve the problems of difficulty in controlling the gripping force, the deviation of the shape and posture, and the damage of the inner claw workpiece. Simple effect of force process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

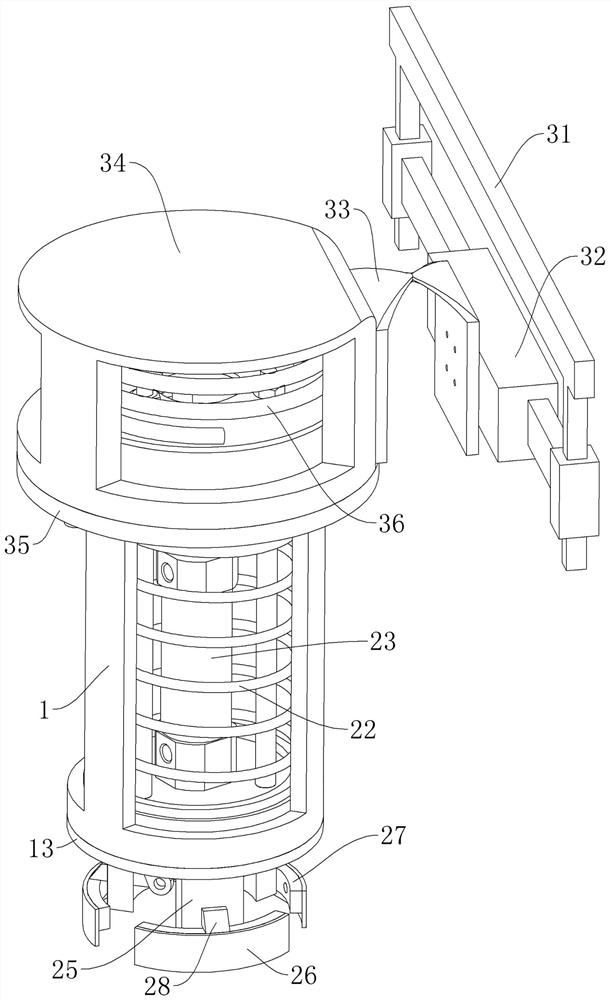

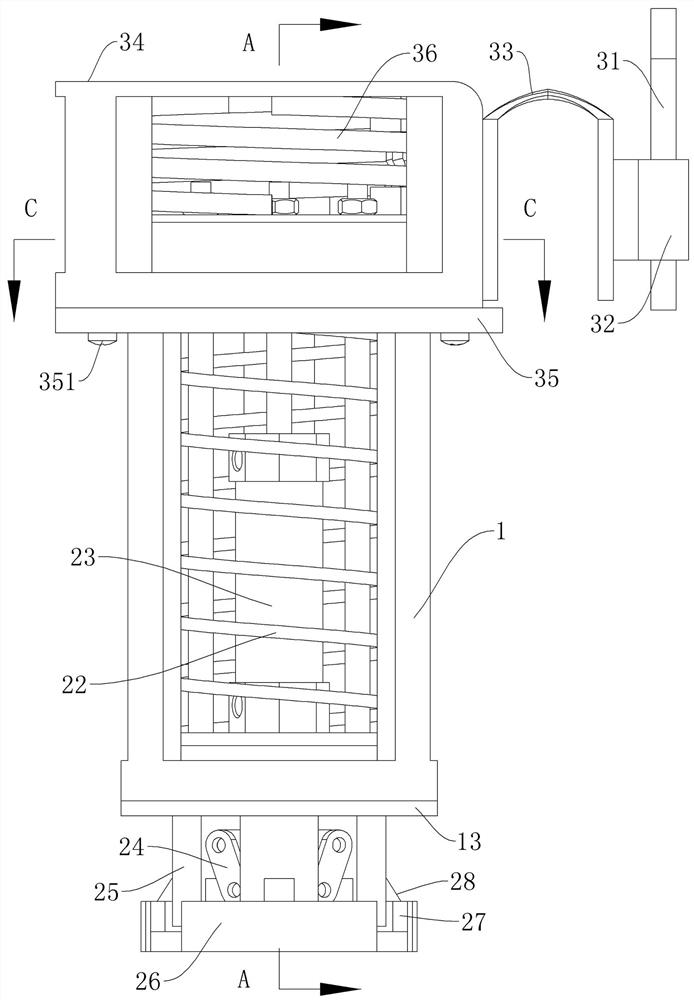

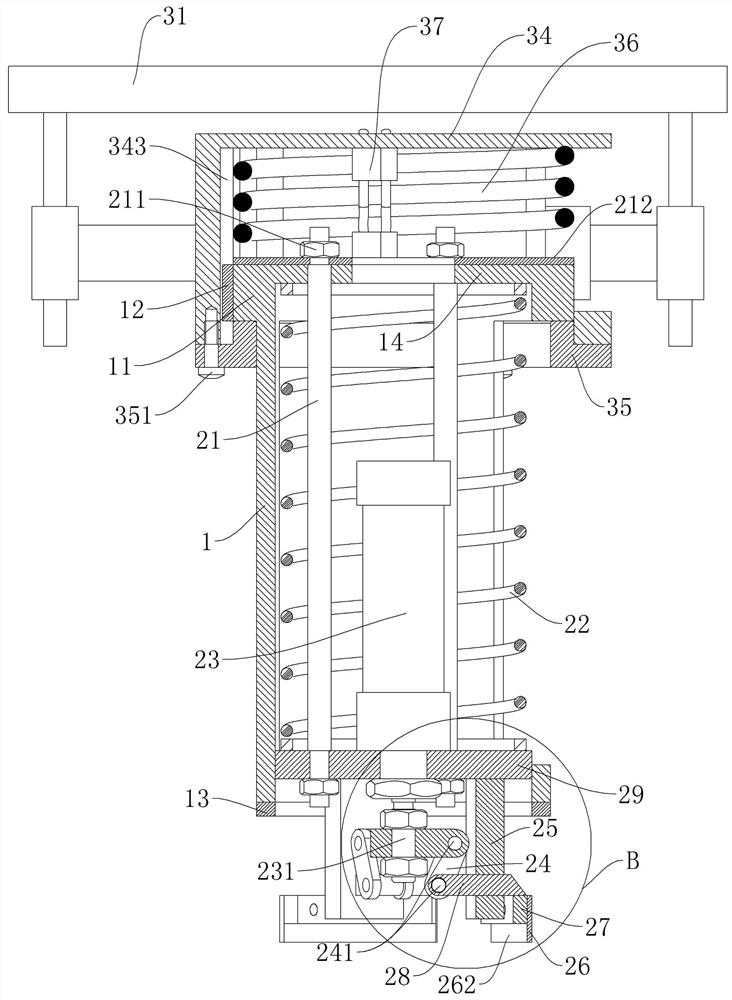

[0045] Embodiment one, see Figure 1-14 , the self-adaptive and compliant manipulator of the internal support type operation of the fragile thin-walled cylindrical inner wall workpiece, the manipulator includes an external cylindrical sleeve, a grasping device installed in the sleeve, and an adaptive connection device installed on the upper end of the sleeve;

[0046] The grabbing device includes:

[0047] a disc-shaped body matching the diameter of the inner cylindrical surface of the sleeve;

[0048] At least three identical inner support mechanisms arranged on the lower surface of the disc-shaped main body and distributed uniformly along the circumference;

[0049] A telescopic linear motion driver installed in the middle of the upper surface of the disc-shaped main body, passing through the disc-shaped main body to its lower surface, and connected to the inner support mechanism;

[0050] The running direction of the movable part of the linear motion driver is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com