Inner-supported flexible manipulator for grasping and assembling fragile thin-walled cylindrical workpieces

A technology of thin-walled cylinders and manipulators, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of difficult control of inner support claws, damage to workpieces, easily damaged workpieces, etc., to achieve easy grasping of workpieces, simple stress process, and difficult damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

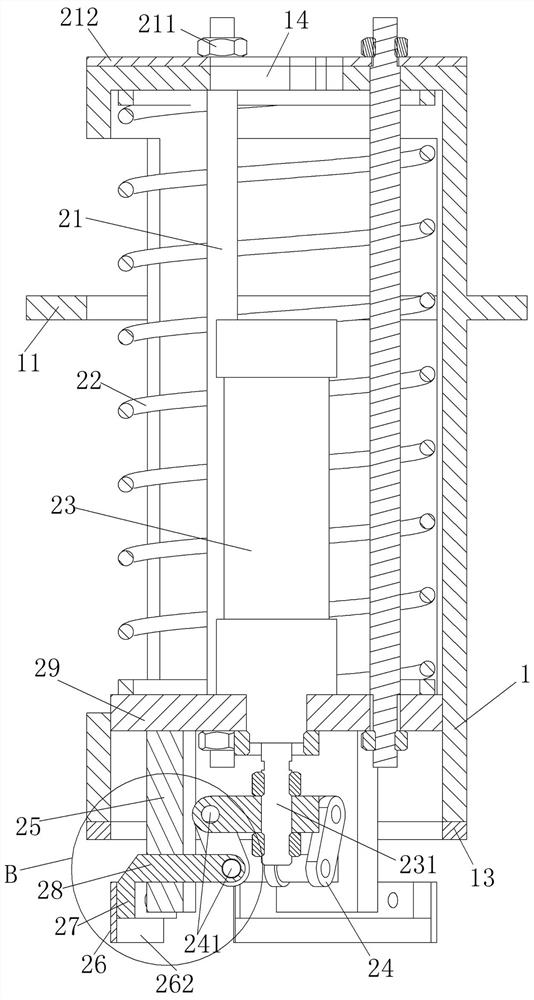

[0039] Example 1, see Figure 1-10 The inner support and assembly of the fragile wall cylindrical inner wall workpiece, the robot including the outer cylindrical sleeve and a grab device mounted in the sleeve; the grab device includes: The inner cylindrical diameter of the sleeve is matched; disposed on at least three of the lower surface of the disc main body and the circumference of the circumferentially, mounted in the upper surface of the disc main body, and passes through the disc main body To its lower surface, the telescopic linear motion drive connected to the inner support mechanism; the operation direction of the movable portion of the linear motion driver is the same as the axial direction of the disc body; the disc main body is in the interior of the sleeve, and It is possible to slide along the inner surface of the sleeve; the upper surface of the disc main body is also fixed to a guide rod in the circumferential direction of the circumferential direction and the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com