Gold nanometer particle and method for preparing gold nanometer particle with acoustic suspension

A nanoparticle, acoustic suspension technology, applied in nanotechnology, nanotechnology, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

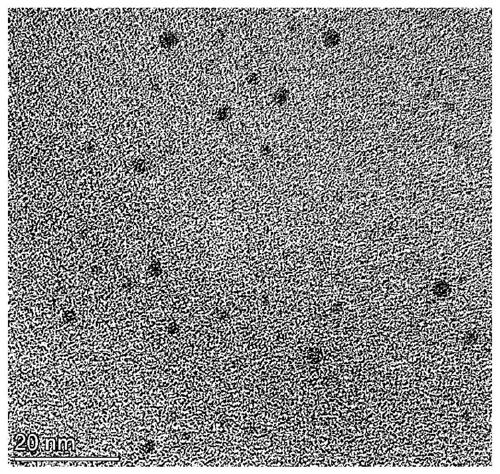

Image

Examples

Embodiment 1

[0038] Step (1): Under normal temperature and pressure, take 4.9 mg of HAuCl 4 ·3H 2 O particles, dissolved in 2.5 mL HO 2 O, to get HAuCl 4 ·3H 2 O solution (concentration 5mM). Take 13.3mg of PVP (MW: 58000) powder, dissolve in 2mL H 2 O, obtain PVP solution (concentration 60mM). Take 1.42mg of NaBH 4 powder, dissolved in 0.5mL H 2 O, get NaBH 4 solution (concentration 75mM).

[0039] Step (2): Take 2.5mL of HAuCl prepared in step (1) 4 ·3H 2 O solution was added to 2mL of the prepared PVP solution, and oscillated to make it evenly mixed.

[0040] Step (3): Under normal temperature and pressure, adjust the ultrasonic power of the acoustic levitation instrument to 350W, the ultrasonic frequency to 21KHz, the cross-sectional diameter of the plane transmitting end to 30mm, the curvature radius of the concave reflecting end (spherical surface) to 25mm, and the cross-sectional diameter to 40mm .

[0041] Step (4): Adjust the distance between the emitting end and the ...

Embodiment 2~5

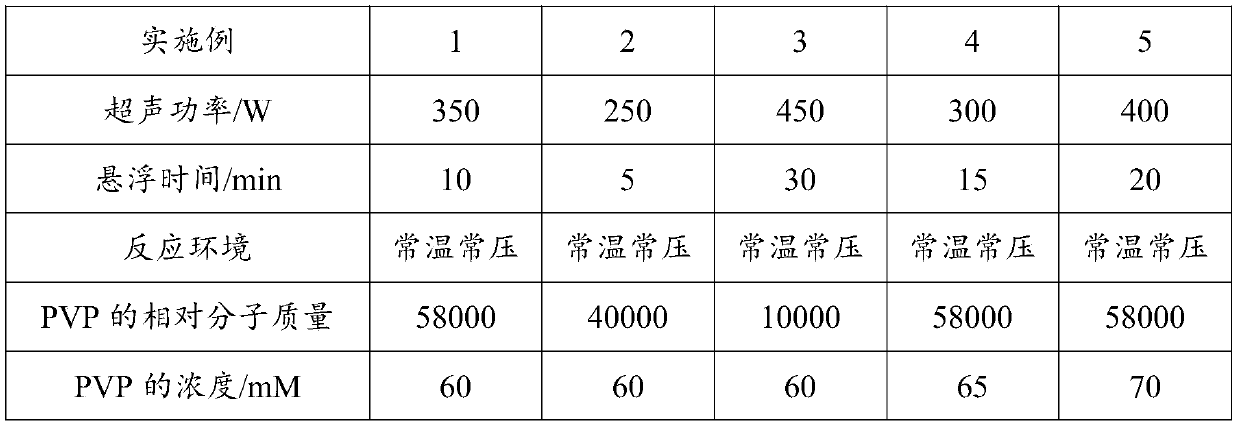

[0045] The operation steps are the same as in Example 1, and some detailed parameters are shown in Table 1.

[0046] The preparation condition of table 1 embodiment 1~5

[0047]

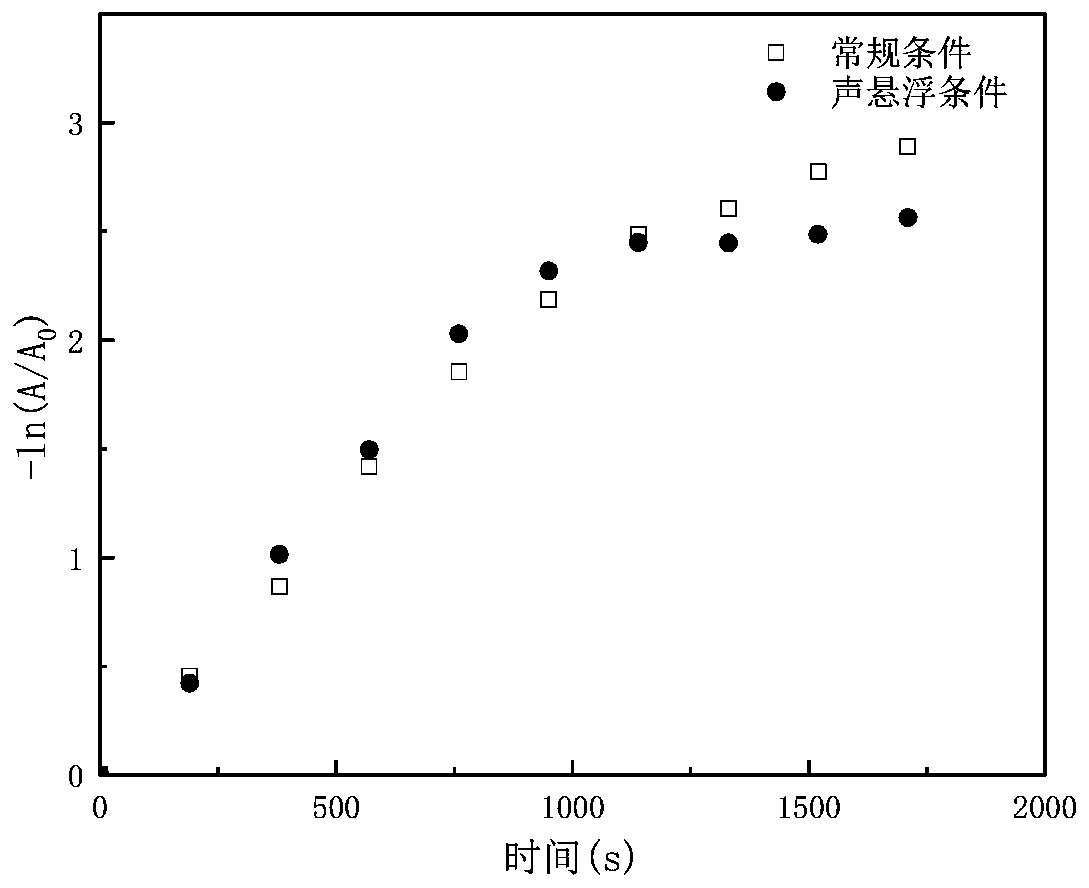

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface diameter | aaaaa | aaaaa |

| Radius of curvature | aaaaa | aaaaa |

| Cross section diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com