Blind-end-free membrane shell

A membrane shell and blind-end technology, applied in the field of non-blind-end membrane shells, can solve the problems of long membrane shell length, dead space of support frame, and large space at both ends, so as to achieve the effect of reasonable structure design and good filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

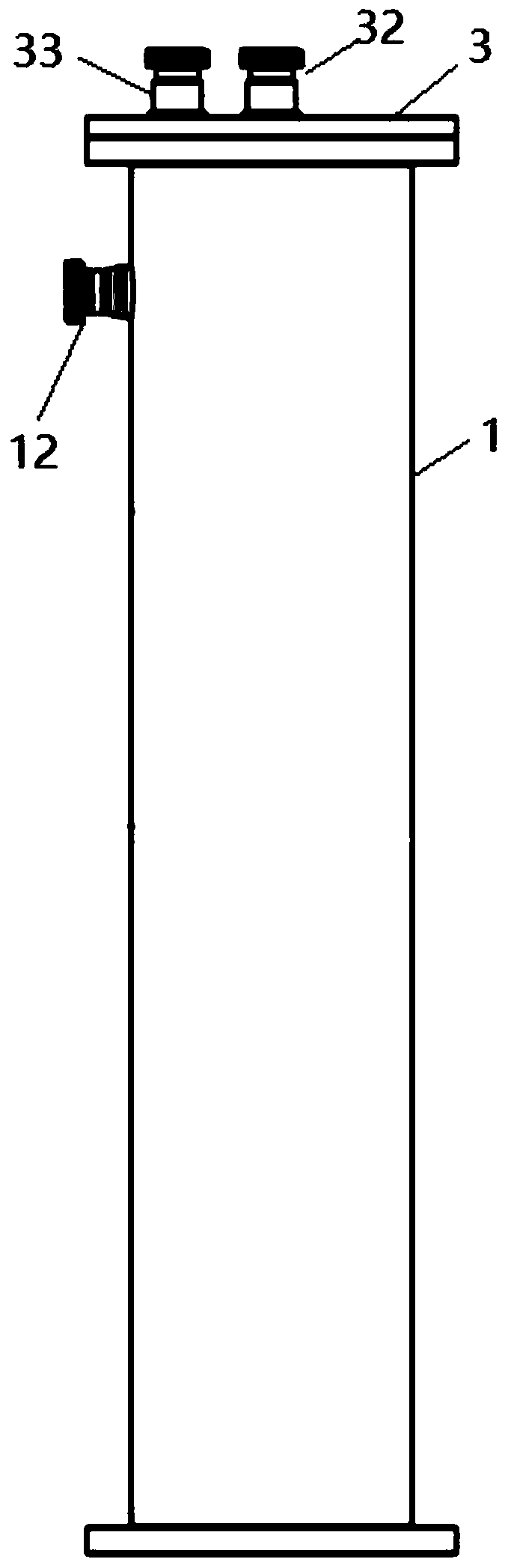

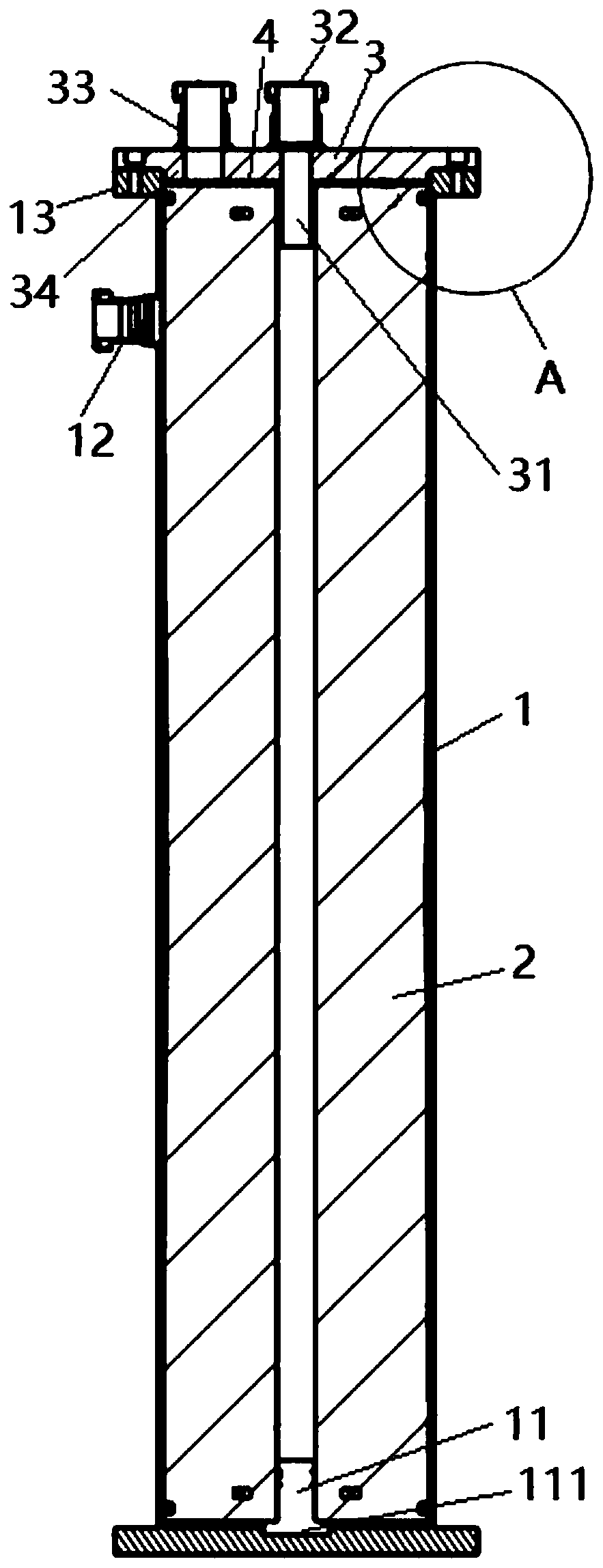

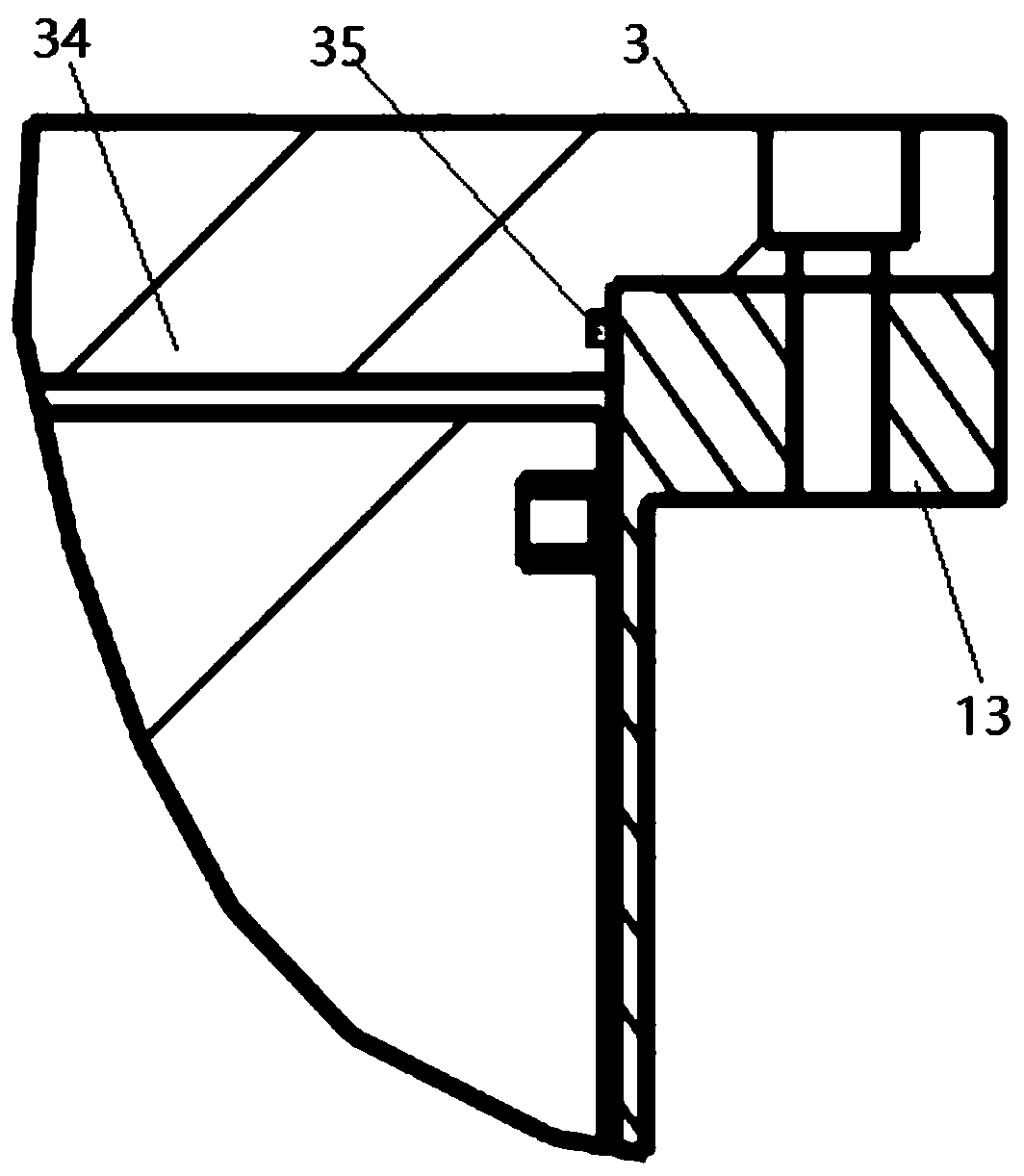

[0029] Example: such as figure 1 and 2 As shown, the non-blind-end membrane shell of this embodiment includes a shell 1, a reverse osmosis membrane 2, and an end cover 3. The shell 1 is a cylindrical structure with one end open, and the end cap 3 is hermetically assembled on the shell 1. The middle part of the inner wall of the other end of the above-mentioned housing 1 is provided with a first positioning rod 11, and the middle part of the above-mentioned end cover 3 extends to the inside of the above-mentioned housing 1 and is provided with a hollow second positioning rod corresponding to the above-mentioned first positioning rod 11. Rod 31, one end side wall of the housing 1 is provided with a concentrated water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com