Production method for re-fermenting soy sauce by using mixed enzyme preparation

A production method and re-fermentation technology, applied in food ingredients as odor improvers, food ingredients as taste improvers, food science, etc., can solve problems such as increasing the freshness of soy sauce, improve taste and aroma, reduce waste, and improve quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

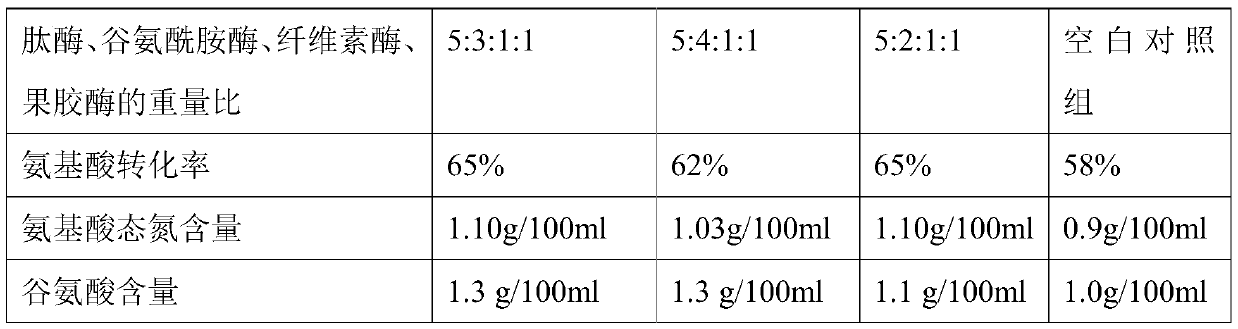

Examples

Embodiment 1

[0031] A kind of production method utilizing mixed enzyme preparation to ferment soy sauce again, comprises the following steps:

[0032] (1) Raw material processing; after the wheat is fried, it is crushed to make wheat flour, and the soybean meal is moistened;

[0033] (2) steaming material; after the soybean meal is moistened with water, the material is continuously steamed, the temperature of the steaming material is 130 ℃, and the time is 10 minutes;

[0034] (3) mixing koji; the steamed soybean meal of step (2) is mixed with the wheat flour prepared in step (1) at a weight ratio of 1.4:1, and lactic acid is added at the same time to adjust the pH of the mixture of soybean meal and wheat flour to 5.8, followed by Enter Aspergillus oryzae and ferment in the pond to obtain koji;

[0035] (4) making moromi; the koji prepared in step (3) is mixed with salt water with a concentration of 23g / 100ml, and then pumped into a fermenter to obtain moromi. The weight ratio of koji and...

Embodiment 2

[0075] A kind of production method utilizing mixed enzyme preparation to ferment soy sauce again, comprises the following steps:

[0076] (1) Raw material processing; after the wheat is fried, it is crushed to make wheat flour, and the soybean meal is moistened;

[0077] (2) Steaming material; after the soybean meal is moistened with water, the material is continuously steamed, the temperature of the steaming material is 130°C, and the time is 5 minutes;

[0078] (3) mixing koji; the soybean meal steamed in step (2) is mixed with the wheat flour prepared in step (1) in a weight ratio of 1.2:1, and lactic acid is added at the same time to adjust the pH of the mixture of soybean meal and wheat flour to 5.5, followed by Enter Aspergillus oryzae, enter the pond and ferment to obtain unstrained spirits koji;

[0079] (4) making soy sauce; mixing the unstrained spirits koji prepared in step (3) with salt water with a concentration of 20 to 25g / 100ml, and then pumping it into a ferm...

Embodiment 3

[0095] A kind of production method utilizing mixed enzyme preparation to ferment soy sauce again, comprises the following steps:

[0096] (1) Raw material processing; after the wheat is fried, it is crushed to make wheat flour, and the soybean meal is moistened;

[0097] (2) steaming material; after the soybean meal is moistened with water, the material is continuously steamed, the temperature of the steaming material is 130 ℃, and the time is 15 minutes;

[0098] (3) mixing koji; the soybean meal steamed in step (2) is mixed with the wheat flour prepared in step (1) in a weight ratio of 1.6:1, and lactic acid is added at the same time to adjust the pH of the mixture of soybean meal and wheat flour to 6.0, followed by Enter Aspergillus oryzae, enter the pond and ferment to obtain unstrained spirits koji;

[0099] (4) making soy sauce; the koji prepared in step (3) is mixed with salt water with a concentration of 25g / 100ml, and then pumped into a fermenter to obtain soy mash, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com