Deepwater oil and gas field underwater facility and hydrate unblocking method thereof

A technology for oil and gas fields and hydrates, which is applied in earthwork drilling, cleaning equipment, and production fluids, etc. It can solve the problems of easy blockage of hydrates and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

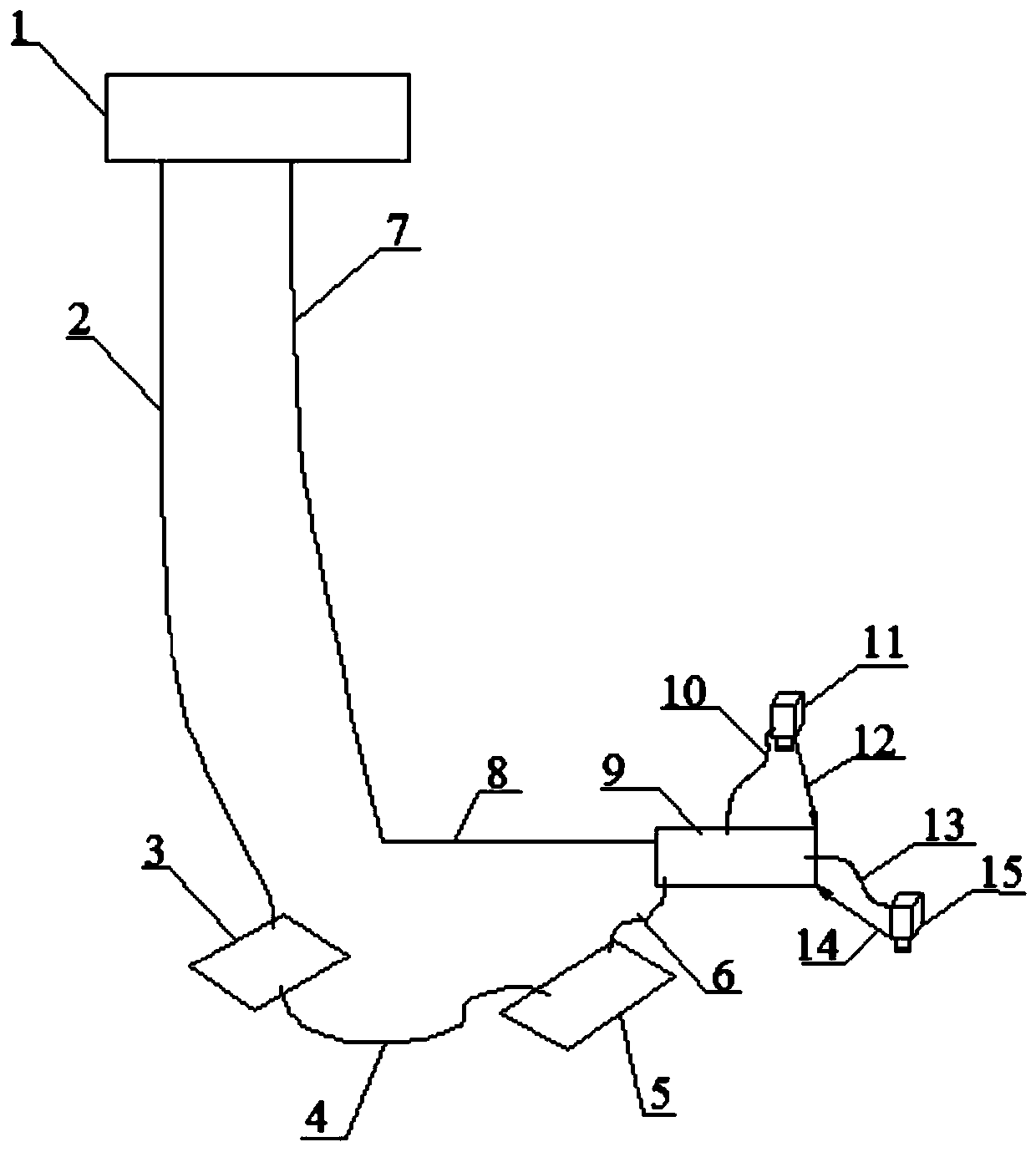

[0040] Embodiment 1 provides a deep-water oil and gas field underwater facility in a single-pipe tie-back production mode, and its structure will be described in detail below.

[0041] refer to figure 1 , deepwater oil and gas field underwater facilities act on the first subsea well 11 and the second subsea well 15 in the deep sea, including a production platform 1 and a production manifold 9, when the production pipe system only includes the first production riser 7 and the first When the submarine pipeline is 8 and the production platform 1 extends into the sea through the first production riser 7, and the first production riser 7 is connected to the production manifold 9 through the first submarine pipeline 8 to form a single-pipe tie-back production mode, at this time the production The manifold 9 communicates with the first subsea well 11 through the first subsea well jumper 12 , and the production manifold 9 communicates with the second subsea well 15 through the second ...

Embodiment 2

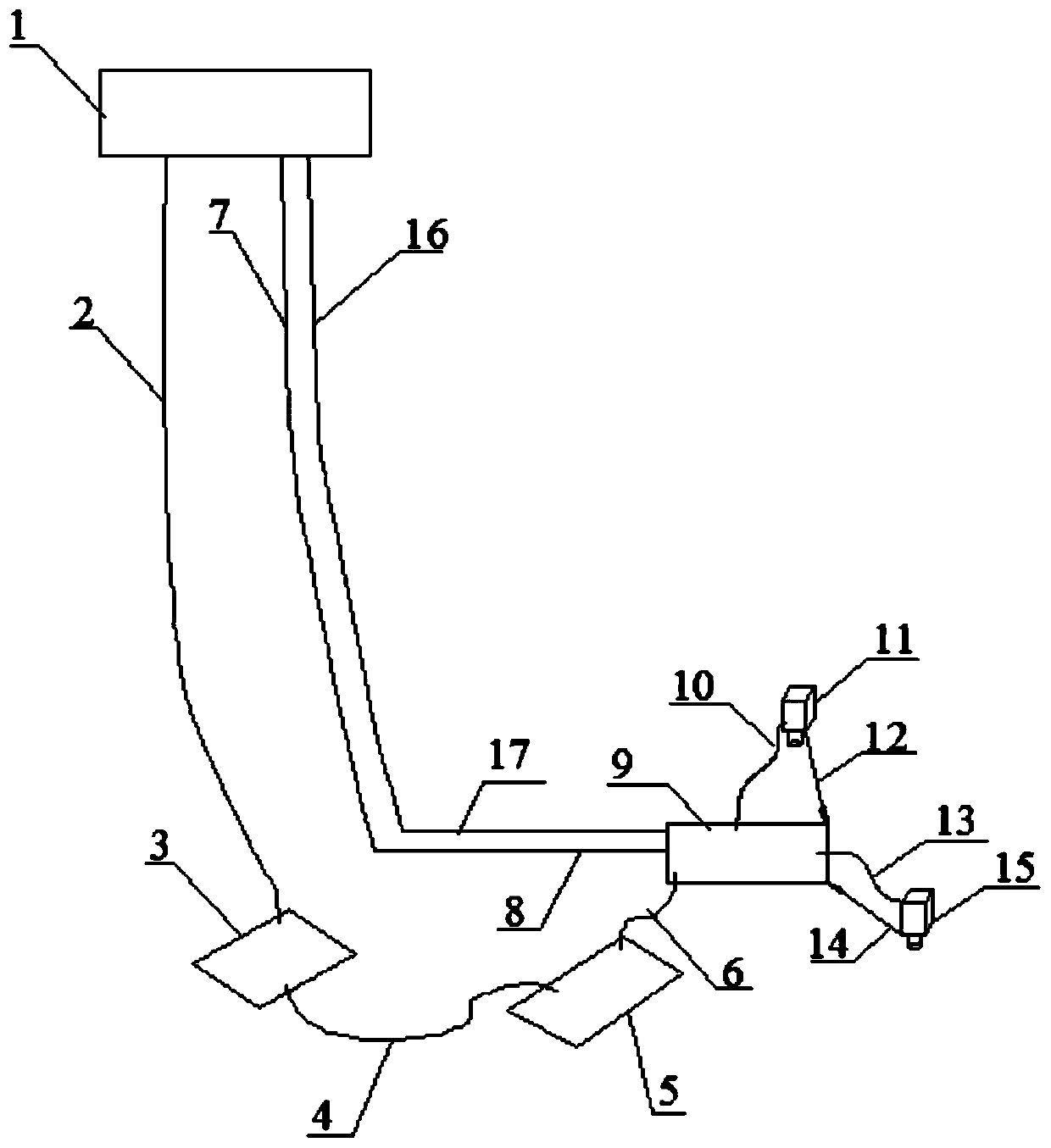

[0046] Embodiment 2 provides a deep-water oil and gas field underwater facility in a double-pipe tie-back production mode. On the basis of Embodiment 1, the production pipe system is improved. The improvements are as follows:

[0047] refer to figure 2, when the production pipe system includes the first production riser 7, the second production riser 16, the first subsea pipeline 8 and the second subsea pipeline 17, a double-pipe tie-back production mode is formed, and the double-pipe tie-back production mode also includes a Production platform 1 and a production manifold 9, the production platform 1 extends into the sea through the first production riser 7 and the second production riser 16 respectively, the first production riser 7 and the second production riser 16 pass through the first production riser 16 respectively The subsea pipeline 8 and the second subsea pipeline 17 communicate to a production manifold 9 .

[0048] The structure of the cable tube and its connecti...

Embodiment 3

[0050] Embodiment 3 provides a method for unplugging hydrates in underwater facilities of deep-water oil and gas fields, using the underwater facilities of deep-water oil and gas fields in Embodiment 1, and the method for unplugging includes the following steps:

[0051] Step S1: Determine the location and type of blockage.

[0052] If the hydrate blockage is located in the production riser or subsea pipeline, it is determined to be the type of hydrate blockage in the production manifold;

[0053] If the hydrate blockage is located at the subsea wellhead or at the jumper, it is determined to be the type of hydrate blockage near the subsea well.

[0054] Step S2: Implement depressurization on both sides according to the blockage type.

[0055] For the type of hydrate blockage in the production manifold in the single-pipe tie-back production mode, the depressurization scheme in the subsea facilities of deepwater oil and gas fields includes the following steps:

[0056] Shuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com