Intelligent spraying robot for outer wall of high-rise building and control method of intelligent spraying robot

The technology of a spraying robot and a control method is applied in the direction of the spring mechanism, the load hanging element, the hoisting device, etc., and can solve the problems of high labor intensity of manual operation, uneven spraying, and uncertainty of coating quality, etc. Achieve stable and reliable moving process, improve spraying quality, and improve spraying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

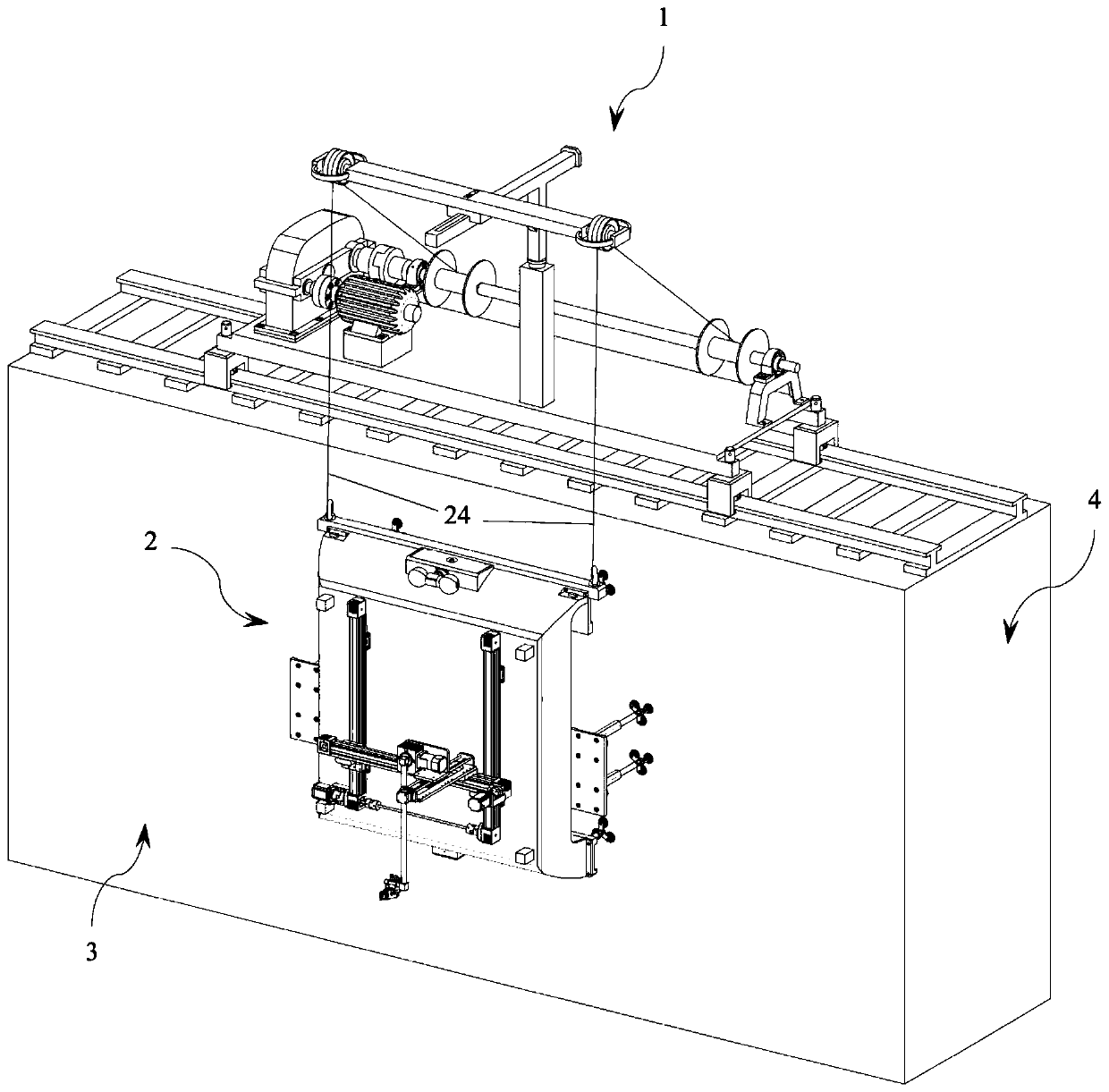

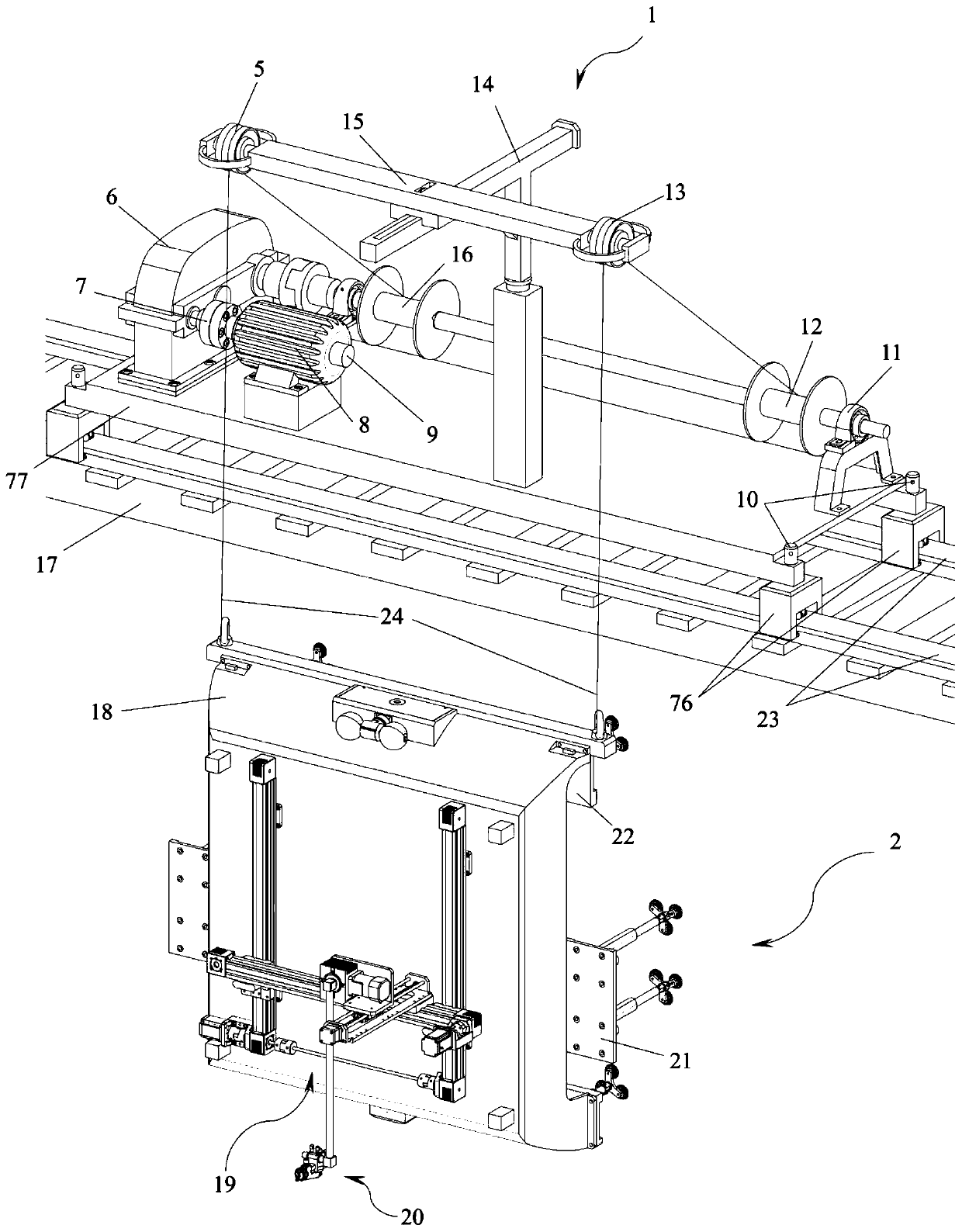

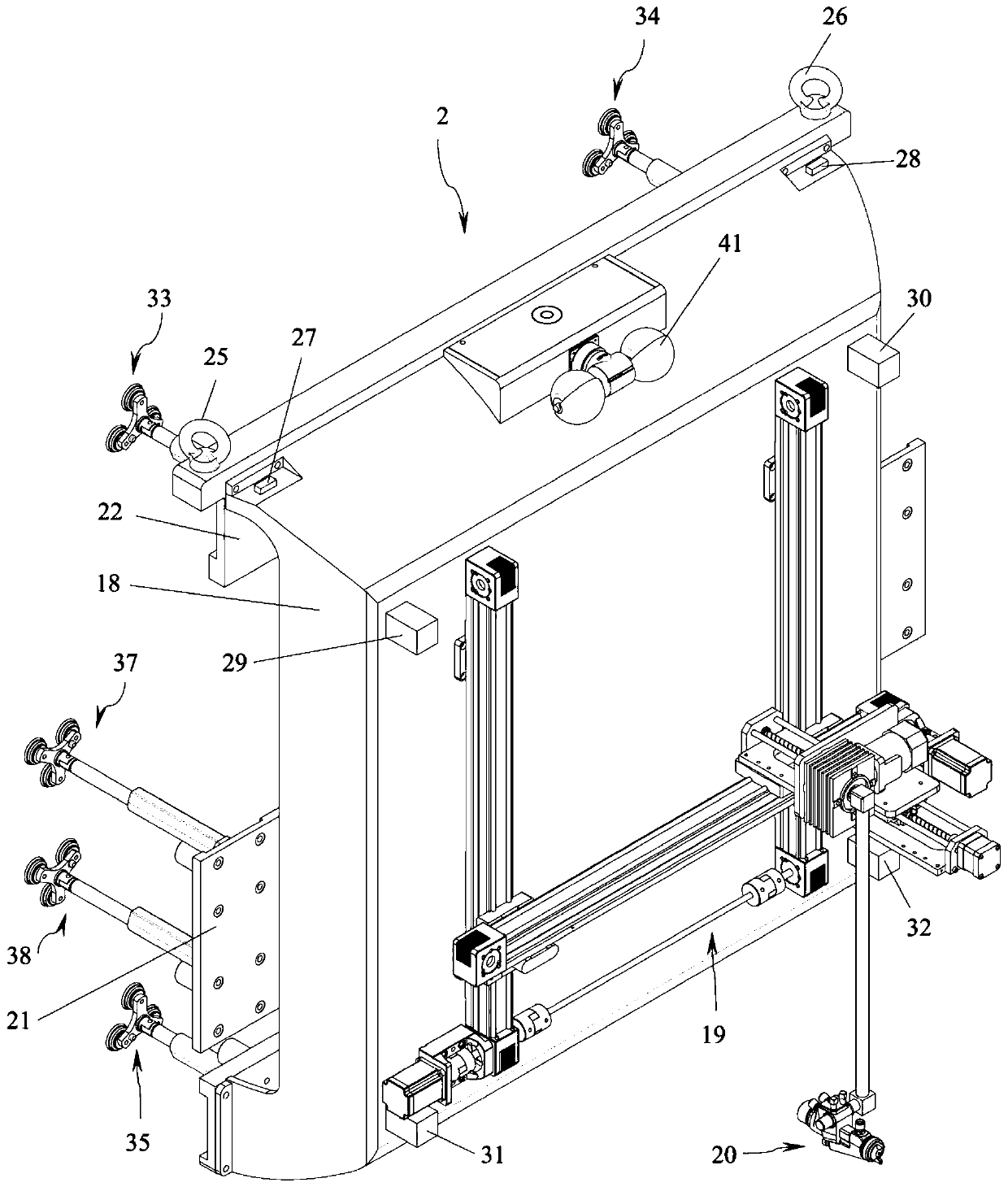

[0046] see figure 1 and figure 2 In this embodiment, the intelligent spraying robot on the outer wall of a high-rise building is composed of an upper body 1 and a lower body 2, the upper body 1 is installed on the roof 17 of the building 4, and the lower body 2 is attached to the outer wall 3 of the building 4.

[0047] Such as figure 1 As shown, the structural form of the upper body 1 is: on the roof 17 and along the outer edge of the roof 17, a track 23 is set, and a sliding block 76 is arranged on the track 23, and the platform 77 is supported on the sliding block 76, and can move along the The track 23 moves; hoisting equipment is set on the platform 77, the hoisting equipment includes a hoisting motor 8 with an encoder 9, the hoisting motor 8 drives the reel through the hoisting transmission mechanism, and one end of the rope 24 is wound on the reel , and the other end is connected to the lug of the lower body 2 after being turned by the fixed pulley, and the lower bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com