Cloth accurate falling printing and dyeing cloth collection device

A fabric and accurate technology, applied in the field of textile printing and dyeing machinery, can solve the problems of inaccurate blanking of fabrics, failure to load fabrics in carts, messy fabrics, etc., and achieve the effect of accurate docking positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

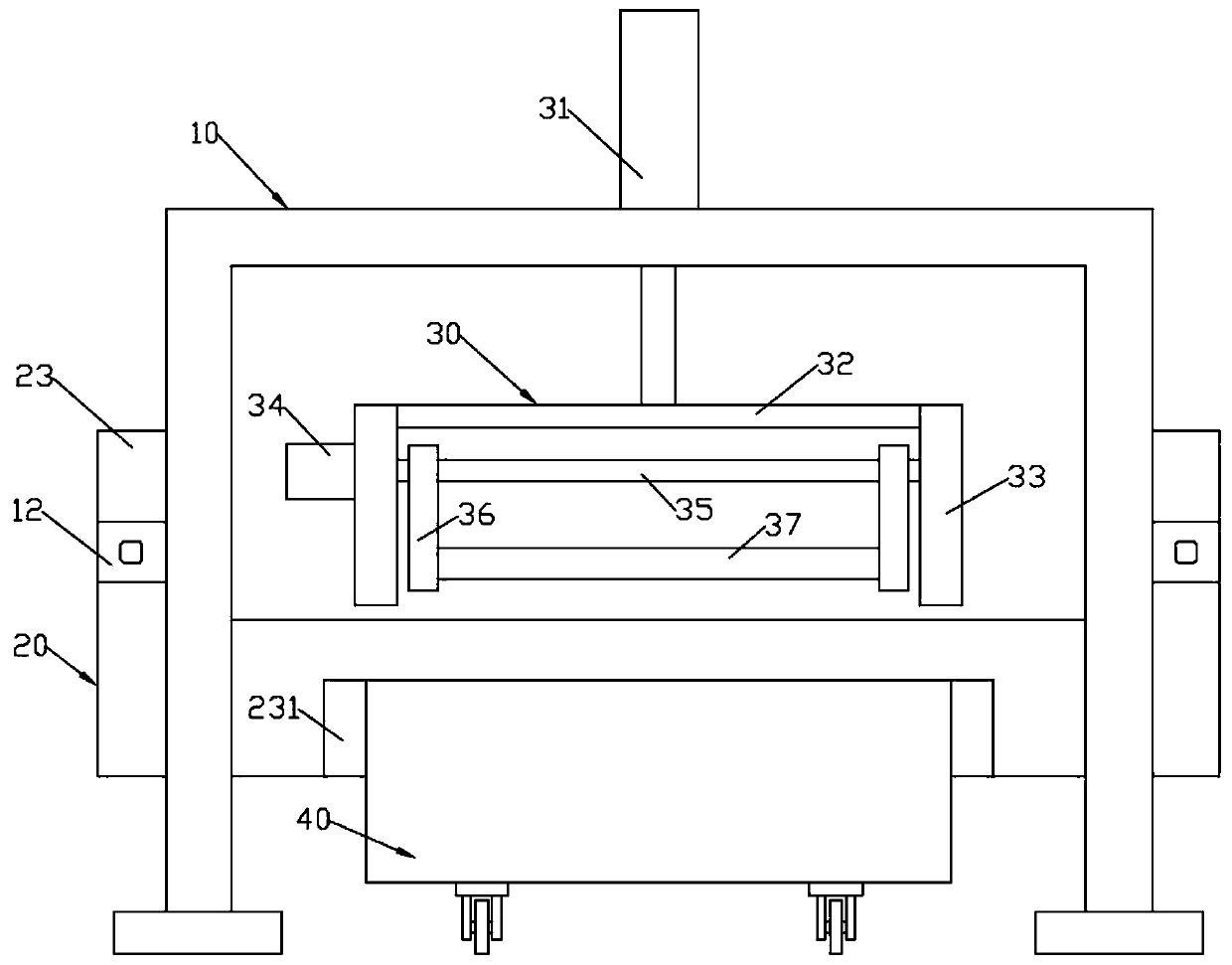

[0013] Such as figure 1 , figure 2 As shown, a cloth receiving device for printing and dyeing with accurate falling of cloth includes a bracket 10, a trolley limit device 20, a cloth receiving device 30 and a push cart 40; The vertical part symmetrically arranged on the left and right and the horizontal part formed on the upper end surface of the vertical part; Swing support plates 33 are respectively formed at the ends; swing plates 36 are respectively rotated on the end faces close to the pair of swing support plates 33, and the pair of swing plates 36 are synchronously rotated; The cloth driving roller 37; the cart limit device 20 includes a limit support plate 23 which moves back and forth and is arranged on the front side of the support 10; the front end surface of the limit support plate 23 is formed with a pair of left and right limit plates 231 symmetrically arranged; The left and right width of the push cart 40 is equal to the left and right spacing of a pair of le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com