A foam filling machine for shock absorption in logistics packaging

A foam filling and logistics technology, applied in the field of logistics packaging, can solve the problems of large equipment wear, high labor costs, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

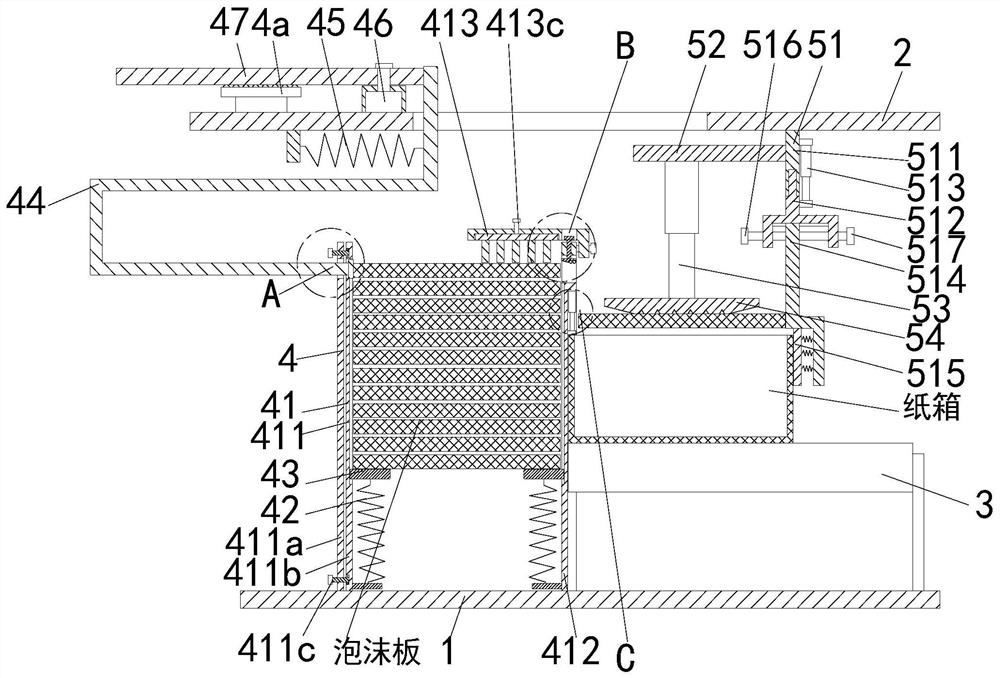

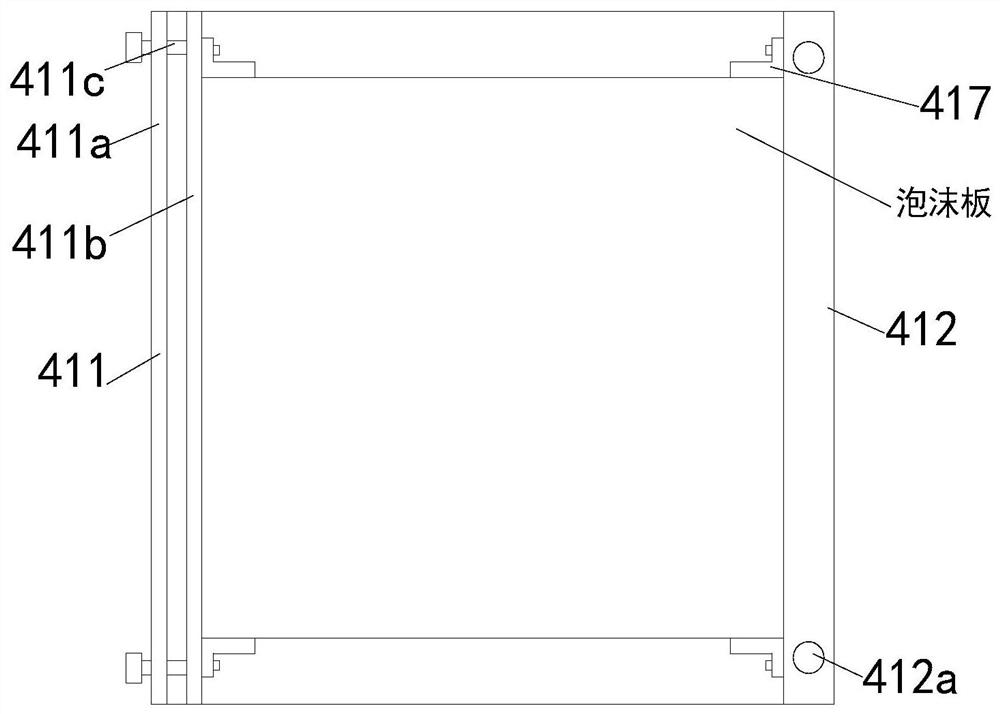

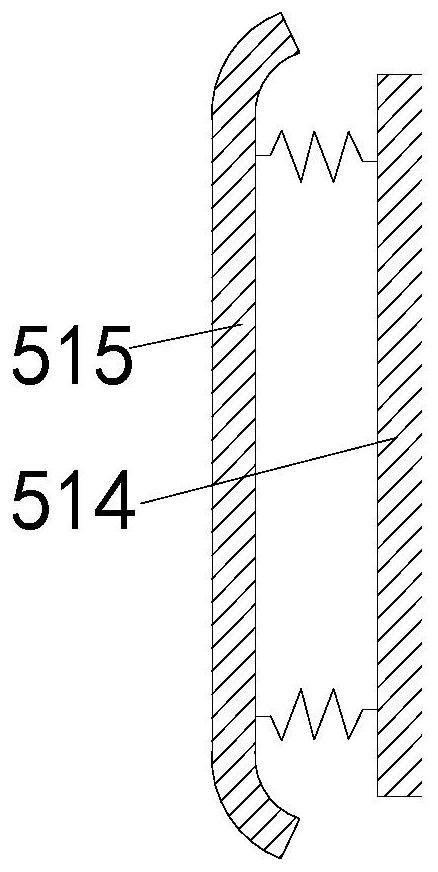

[0030] Such as Figure 1 to Figure 6 As shown, a foam filling machine for shock absorption in logistics packaging includes a bottom plate 1, a top plate 2, a conveyor belt 3, a feeding mechanism 4, and a filling mechanism. A feeding mechanism 4 is installed, a filling mechanism is installed at the lower end of the top plate 2, a conveyor belt 3 is arranged at the lower end of the filling mechanism, the conveyor belt 3 is installed on the bottom plate 1, and a sliding groove is opened on the top plate 2; wherein:

[0031]Described feeding mechanism 4 comprises storage rack 41, lifting spring 42, lifting plate 43, pushing frame 44, back-moving spring 45, drive motor 46 and drive cam 47, and storage rack 41 is installed on the base plate 1, and storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com