Special clamping tool for robot for live replacement of strain single insulator of ultrahigh-voltage line

A technology of live replacement and ultra-high voltage, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of dangerous working environment for construction workers, replacement of bad insulators, high labor intensity, etc., to improve maintenance efficiency, reduce power outage time, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

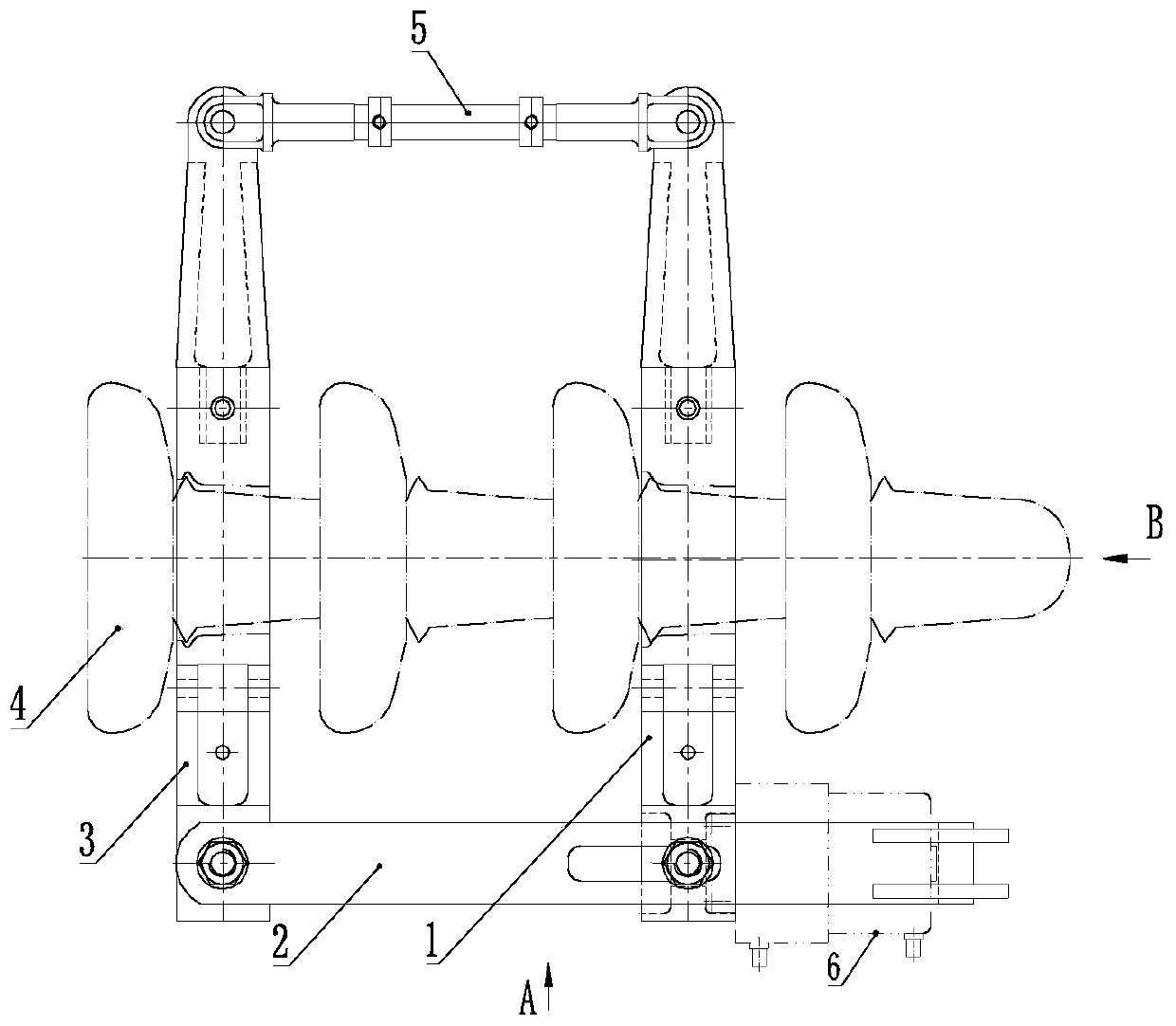

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as Figure 1 to Figure 3 As shown, the robot-specific jig for replacing tension-resistant single-piece insulators of ultra-high-voltage lines with power on includes front clamp 3, rear clamp 1, adjusting screw 5, and pull plate frame assembly 2. The position on the steel cap of the insulator is different, usually divided into front clamp 3 and rear clamp 1. Generally, the clamp close to the cross arm end is called the front clamp 3, and the clamp close to the wire end is called the rear clamp 1. Refer to Figure 6 , Figure 9 to Figure 16 , the front card 3 and the rear card 1 described in this patent both include a main body 101 and an upper cover 102, one end of the upper cover 102 is hinged on the main body 101 through a pin 104, the other end of the upper cover 102 is provided with a threaded hole, the upper cover 102 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com