Method for simplifying detailed chemical reaction mechanism

A chemical reaction mechanism and mechanism technology, applied in the field of computer numerical simulation, can solve the problems of reducing components and elementary reactions, and the limited ability to identify redundant components and elementary reactions, so as to achieve the reduction of components and elementary reactions , good combustion and emission effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

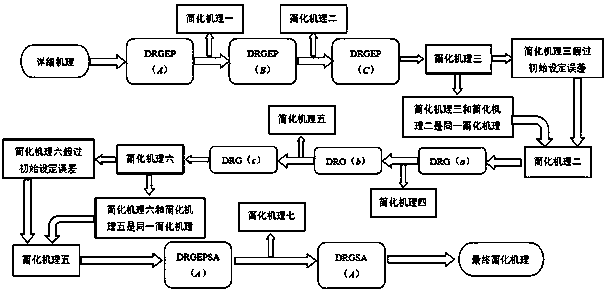

[0029] The simplified method of the detailed chemical reaction mechanism of this embodiment, such as figure 1 shown, including the following steps:

[0030] S1: Bring the detailed chemical reaction mechanism into the reactor for calculation, obtain the target parameters of the detailed chemical reaction mechanism, and initially set the error of the target parameters;

[0031] S2: First choose DRGEP as the first mechanism simplification method for preliminary simplification. The initial threshold is set to A. Simplified mechanism 1 is obtained, which is brought into the reactor calculation to obtain the target parameters of the simplified mechanism and compare with the target parameters obtained from the detailed mechanism. , to get the maximum relative error of the target parameter;

[0032] S3: Based on the simplified mechanism 1, continue to use the DRGEP method and increase the threshold value to B to obtain the simplified mechanism 2, bring it into the reactor calculation...

Embodiment 2

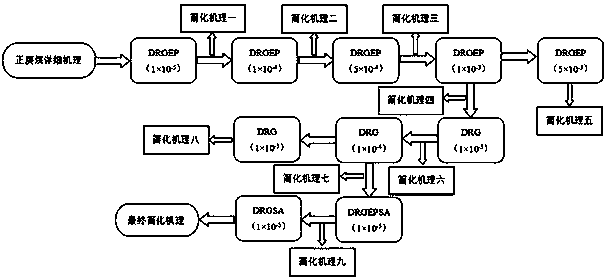

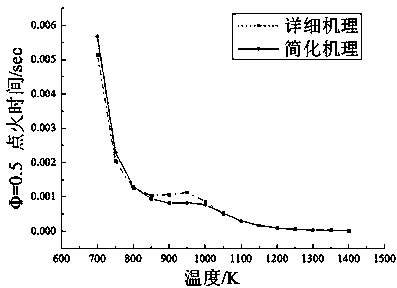

[0040] In this embodiment, the mechanism of n-heptane is simplified as figure 2 , set the reactor equivalence ratio: 0.5~1.5, pressure: 5Mpa, temperature: 700~1400K, first bring the detailed mechanism of n-heptane into the homogeneous reactor for calculation, and obtain the detailed mechanism of the flame delay period. Then simplify the detailed mechanism. Two methods, DRGEP and DRG, are used for preliminary simplification. Firstly, DRGEP is selected as the first mechanism simplification method for preliminary simplification, and the initial threshold is set to 1×10 -5 , get the simplified mechanism 1, bring it into the homogeneous reactor calculation, get the flame delay period of the simplified mechanism, and compare it with the flame delay period obtained from the detailed mechanism, the maximum relative error of the flame delay period is 23.66%, taking the simplified mechanism 1 as Basic, continue to use the DRGEP method and increase the threshold to 1×10 -4 , the simpli...

Embodiment 3

[0044] The methane mechanism of this embodiment is simplified as Figure 4 , set the reactor equivalence ratio: 0.5~1.5, pressure: 5Mpa, temperature: 750~1400K, first bring the detailed mechanism of n-heptane into the homogeneous reactor for calculation, and obtain the detailed mechanism of the flame delay period. Then the detailed mechanism is simplified, and the two methods of DRGEP and DRG are used for preliminary simplification. First choose the DRGEP method, and the initial threshold is set to 1×10 -5 , get the simplified mechanism 1, bring it into the calculation of the homogeneous reactor, get the ignition delay period of the simplified mechanism, and compare it with the ignition delay period obtained from the detailed mechanism, the maximum relative error of the ignition delay period is 16.79%, based on the simplified mechanism 1 , increasing the threshold to 1×10 -4 , the simplified mechanism 2 is obtained, the maximum relative error of the ignition delay period is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com