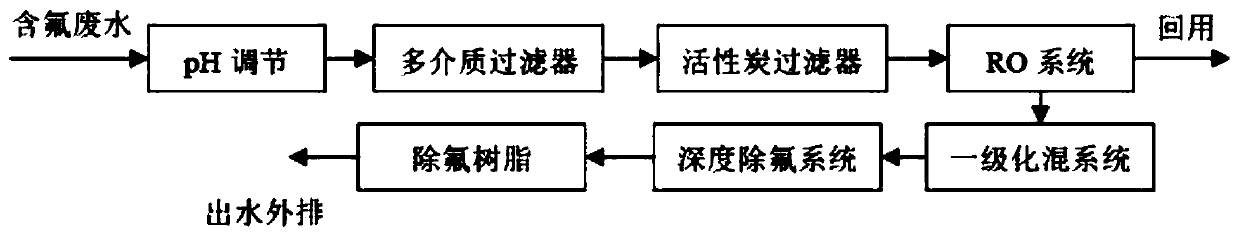

Advanced treatment and recycling system and process for fluorine-containing wastewater in electronic industry

A technology of advanced treatment and electronics industry, applied in the field of water treatment, it can solve the problems of inability to realize the recycling and reuse of fluorine-containing wastewater, and it is difficult to take into account the treatment effect and economy. To achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

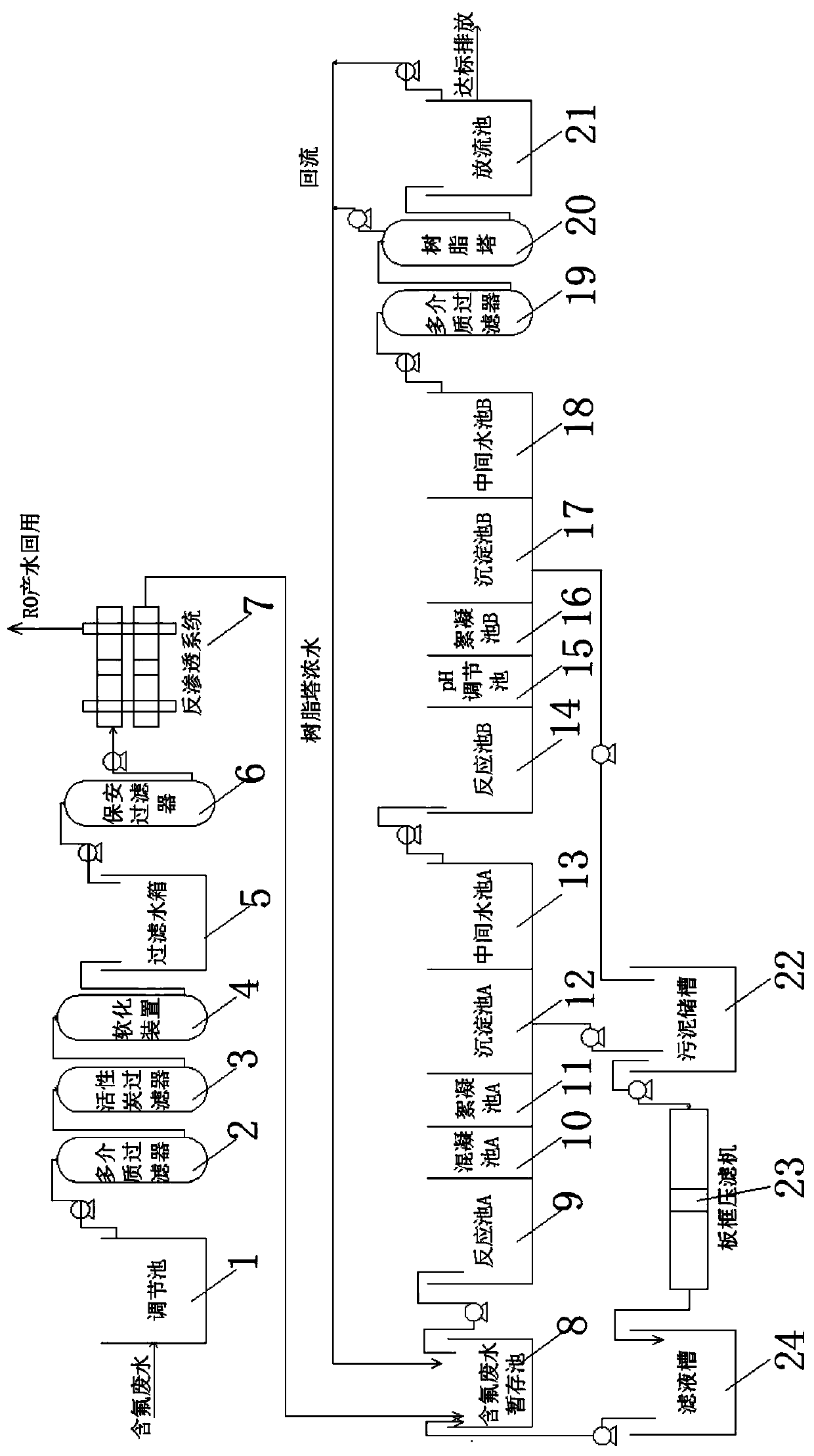

[0054] Water quality of fluorine-containing wastewater in a semiconductor factory: pH is 1.5~3, F is 300~400mg / L, TDS is 250~300mg / L, wastewater flow rate is 3000m 3 / d. The implementation of this case includes the following steps:

[0055] The first step: adjust the pH to 7, and enter the multi-media filter and activated carbon filter. Before the multi-layer filter, there are pH adjustment, bactericide dosing unit and coagulant dosing unit. The fluorine-containing wastewater filtered by the activated carbon filter then flows into the softening resin tower, and the hardness of the fluoride-containing wastewater is less than 1 mg / L at this time.

[0056] Step 2: Filter the effluent into the RO system. The final water production rate is 77-78%. The concentrated water produced by RO enters the high-concentration fluorine-containing wastewater treatment system, and the RO effluent is reused to the front-end pure water system.

[0057] The third step: the reverse osmosis concentr...

Embodiment 2

[0061] Water quality of fluorine-containing wastewater in a panel factory: pH is 2~3, F is 200~300mg / L, TDS is 500~600mg / L, wastewater flow rate is 2000m 3 / d. The implementation of this case includes the following steps:

[0062] The first step: adjust the pH to 7, and enter the multi-media filter and activated carbon filter. Before the multi-layer filter, there are pH adjustment, bactericide dosing unit and coagulant dosing unit. The fluorine wastewater then flows into the softening resin tower, at this time the hardness of the fluorine wastewater is less than 1mg / L.

[0063] Step 2: Filter the effluent into the RO system, the final water production rate is 75%, the concentrated water produced by RO enters the high-concentration fluorine-containing wastewater treatment system, and the RO effluent is reused to the front-end pure water system.

[0064] The third step: the reverse osmosis concentrated water adjusts the pH to 7 and then enters the first-stage calcification mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com