Intelligent track maintenance robot

A robot and track technology, applied in the field of track intelligent maintenance robots, can solve the problems of low track maintenance efficiency, achieve high construction accuracy, reduce maintenance costs, and reduce misjudgment rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

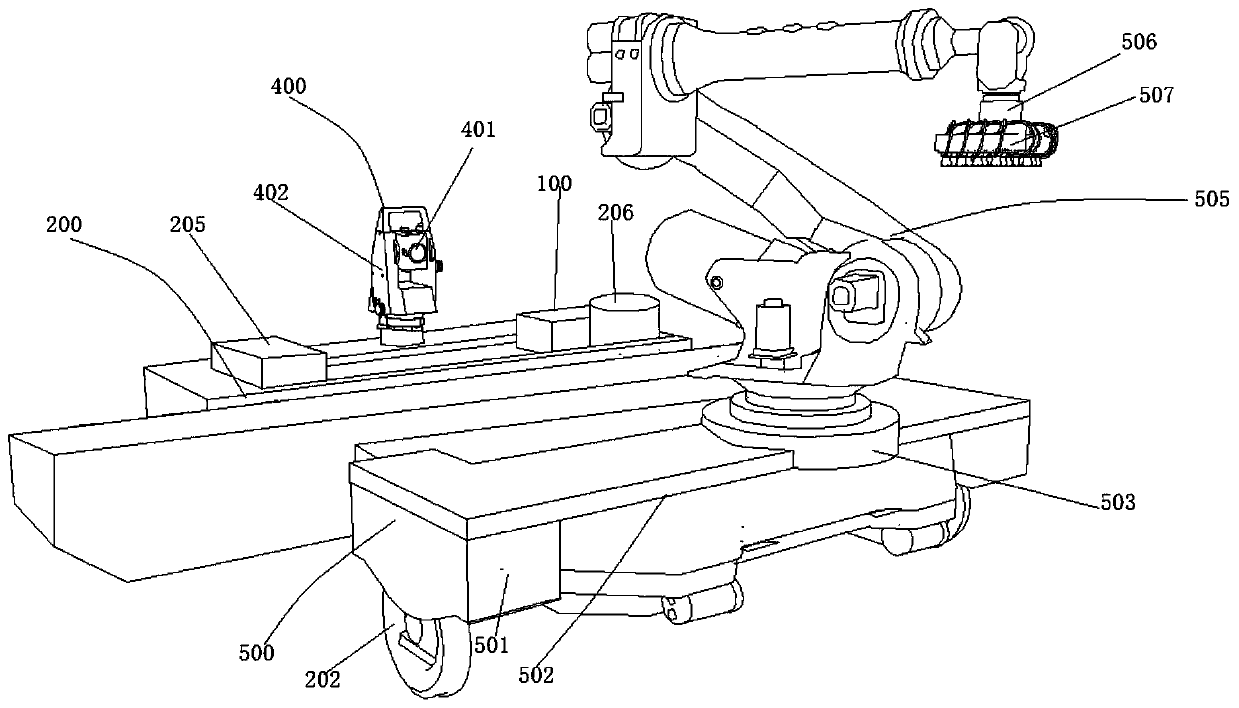

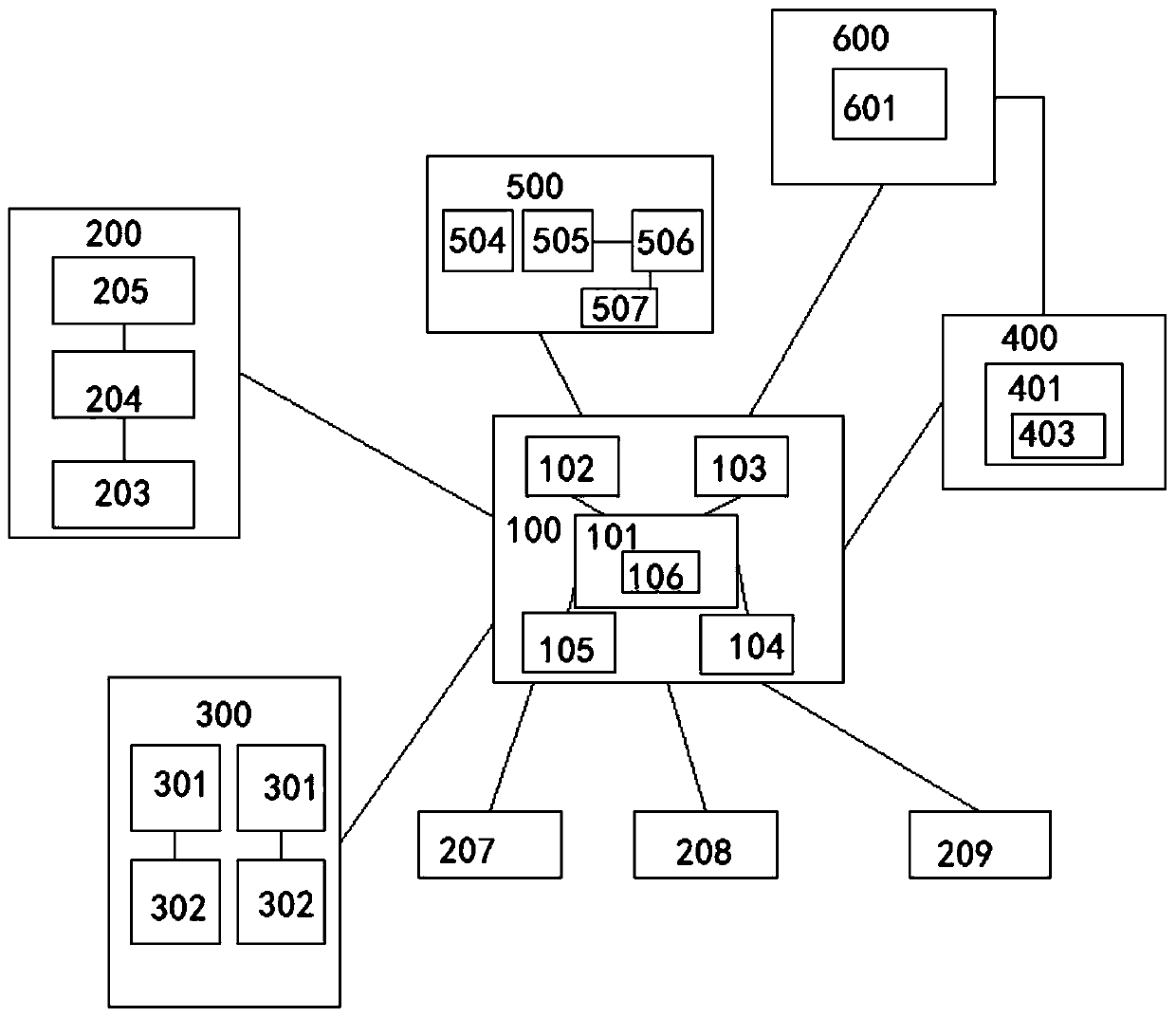

[0041] see Figure 1~2 , a track intelligent maintenance robot provided by the present invention includes: a controller 100, a walking unit 200, a detection unit 300, a monitoring unit 400, a maintenance unit 500 and a remote control unit 600; the controller 100 is equipped with a processor 101 , the controller 100 is communicatively connected with the remote control unit 600; the walking unit 200 includes: an underframe 201, the two sides of the underside of the underframe 201 are provided with traveling wheels 202 at intervals, and the underframe 201 is erected by the traveling wheels 202 On two parallel laid rails (not shown); the driving assembly 203 is set up in the middle of the bottom surface of the underframe 201, and the drive assembly 203 drives the traveling wheels 202 to drive the underframe 201 to advance along the track; the motor 204 is set up on the underframe 201 Above, the input end of the drive assembly 203 is connected to the output end of the motor 204, an...

Embodiment 2

[0066] The upper surface of the underframe 201 is set up with an infrared thermal imager 209 communicatively connected to the controller 100 to form the body temperature detection of construction workers and the transmission of body temperature detection data. The temperature data repository 103.

[0067] The track intelligent maintenance robot monitors the entire construction situation in real time through the monitoring unit 400 and the infrared thermal imager 209 .

[0068] Wherein, the infrared thermal imager 209 is matched with a Heyman thermal imager and an infrared Melexis MLX90614-DC non-contact infrared thermal sensor.

[0069] Equipped with a high-precision infrared thermal imager 209 and a temperature data storage library 103, it can quickly identify human bodies and tracks, and monitor body temperature and temperature.

[0070] Quickly check the body temperature of track line construction personnel and places with a large number of construction personnel. Once a per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com