Flow battery electrode frame, application thereof and flow battery

A liquid flow battery and electrode frame technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as hindering commercialization and industrialization, high cost, loss of sealing function, etc., achieve simple preparation process and reduce stack cost , Conducive to the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

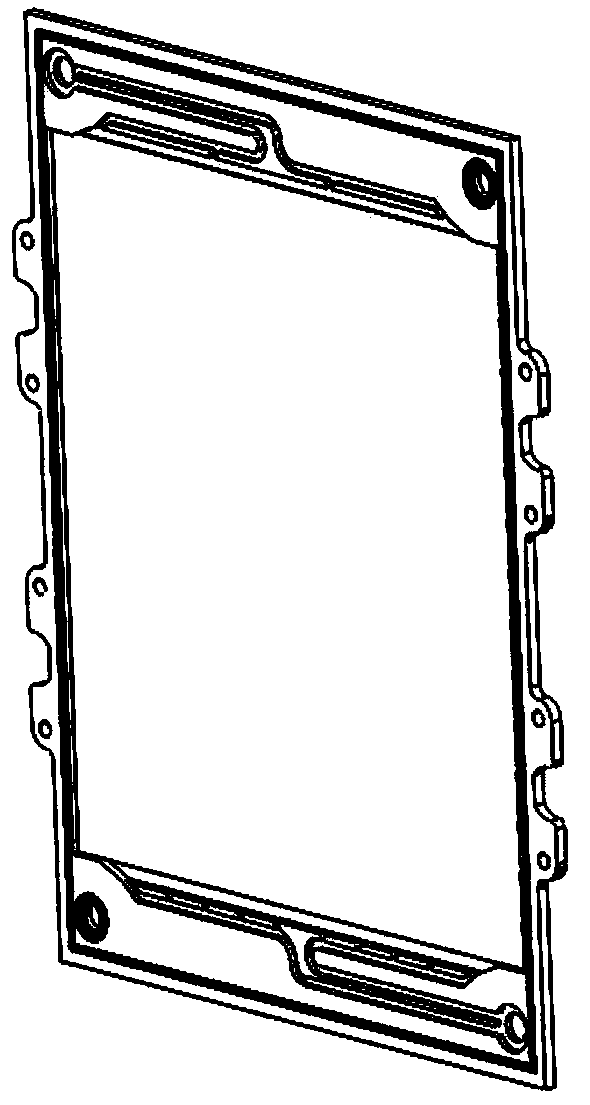

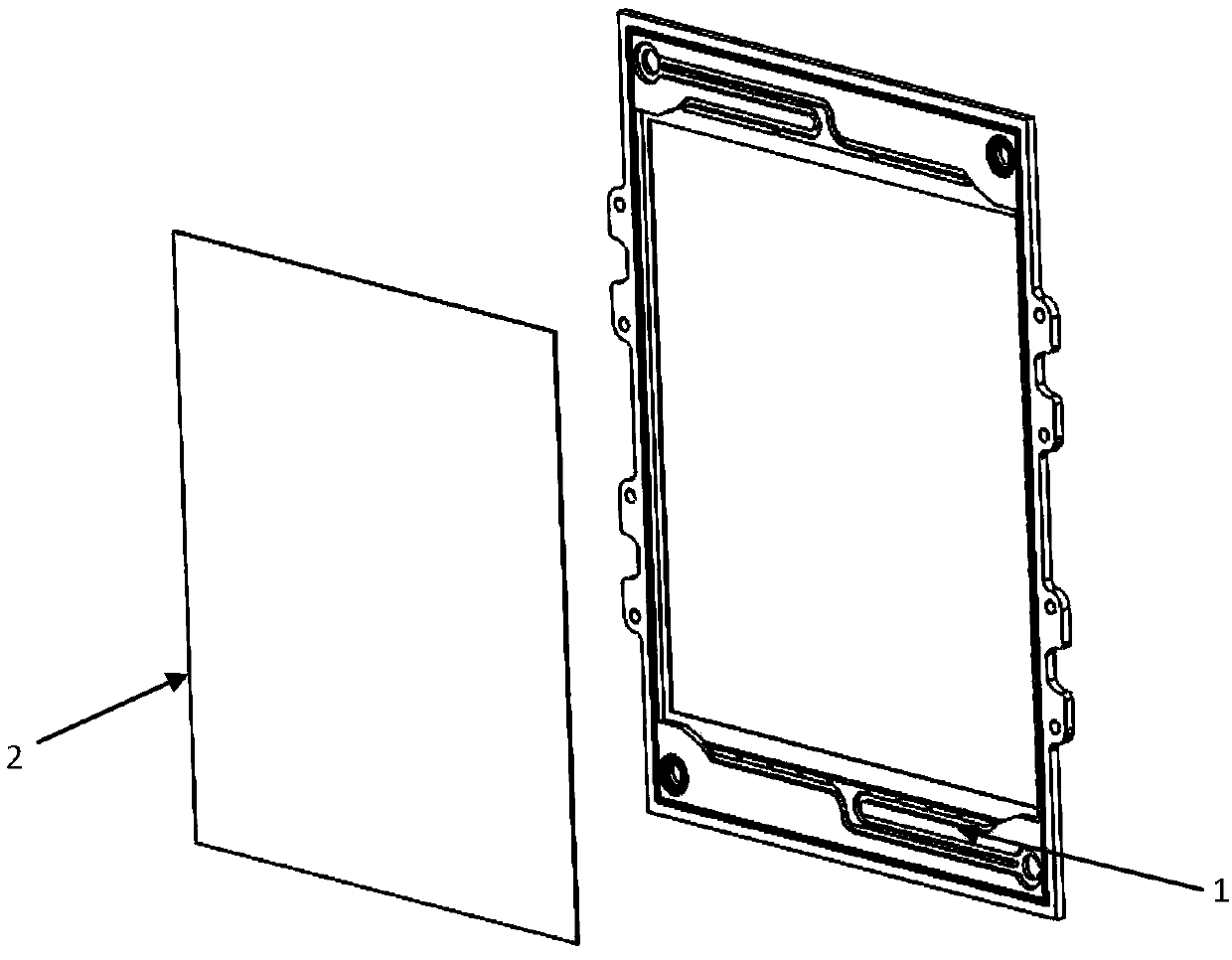

[0025] Place the ion-conducting membrane in the strip-shaped step of the No. 1 electrode frame, which is surrounded by the through hole in the middle and the bottom edge of the groove. Laser welding is used to weld the ion-conducting membrane and the strip-shaped steps together. This constitutes a frame-membrane integrated structure ( figure 1 ). This welding can prevent the active materials in the positive and negative electrodes inside the battery from contacting each other, causing a decrease in the coulombic efficiency of the battery.

[0026] Place the bipolar plate in the strip-shaped step of the No. 2 electrode frame, which is surrounded by the through hole in the middle and the bottom edge of the groove. Laser welding is used to weld the bipolar plate and the strip steps together. This constitutes a frame-plate integrated structure ( figure 2 ). This welding can also prevent the active materials in the positive and negative electrodes inside the battery from cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com