Application of sodium-type sulfonated polyetheretherketone as binder in zinc-nickel redox flow battery electrodes

A technology of sulfonated polyether ether ketone and liquid flow battery, which is applied in battery electrodes, fuel cells, regenerative fuel cells, etc., and can solve problems such as attenuation and unstable performance of binders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

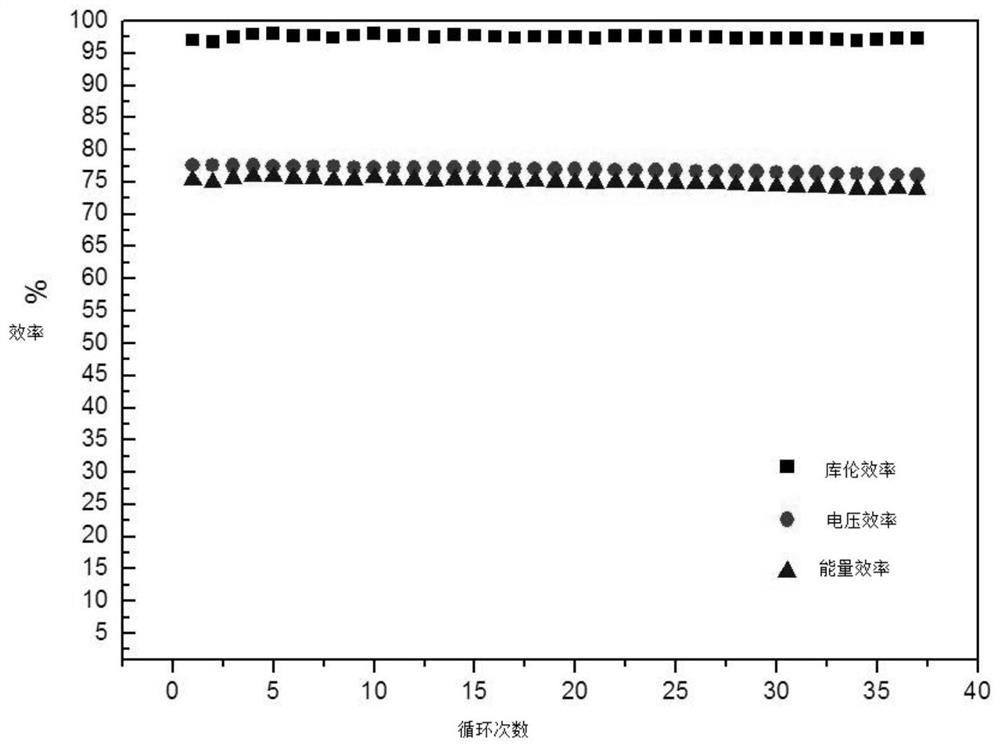

Embodiment 1

[0020] The sulfonated polyetheretherketone resin was soaked in 4M sodium bicarbonate solution at 60°C for 3 hours, washed with water and dried to obtain sodium-formed sulfonated polyetheretherketone (SPEEK) resin.

[0021] Slurry configuration: in parts by weight, 5 parts of sodium-type sulfonated polyether ether ketone, 10 parts of carbon powder, and 85 parts of nickel hydroxide are dissolved in dimethylformamide to obtain a slurry for use; Coating method Apply the slurry evenly on the 36cm 2 On the carbon felt, the carbon felt coated with the slurry is vacuum-dried at high temperature. The drying temperature is 80°C, the drying time is 600s, the vacuum degree is 0 MPa, and the pressure is maintained and the temperature is lowered to room temperature to obtain the electrode product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com