Gas explosion simulation test device and system in underground comprehensive pipe gallery space

An explosion simulation and integrated pipe gallery technology, which is used in fuel testing, measuring devices, material inspection products, etc., can solve problems such as the inability to splicing pipe gallery models, the inability to ensure smooth and smooth pipelines, and the difficulty in realizing free changes in the volume of combustible gases. Achieve comprehensive functions and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

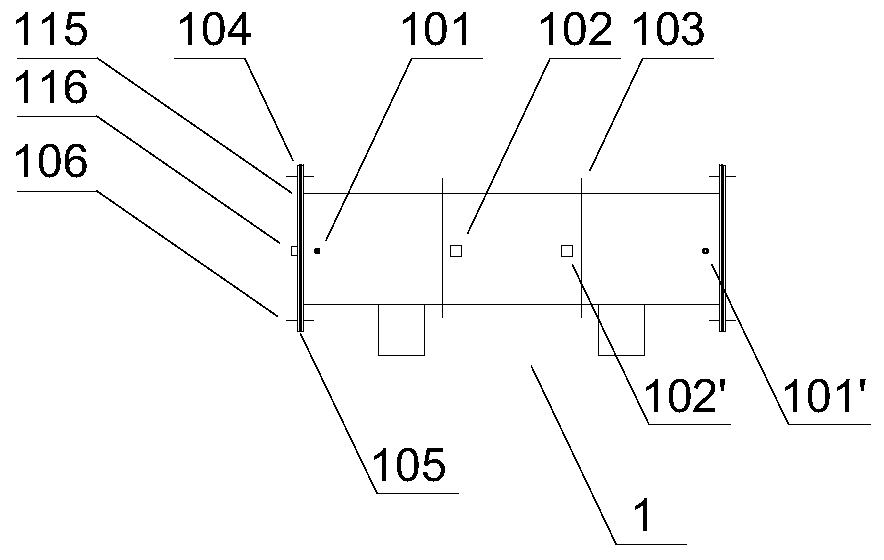

[0062] Embodiment one, as figure 1 As shown, this embodiment provides a gas explosion simulation test device in the space of an underground comprehensive pipe gallery, including a test pipe (1), the test pipe (1) is connected at both ends and includes a basic pipe (11); the basic pipe (11) Both ends are connected and flanges (104) are provided;

[0063] The basic pipeline (11) reserves at least two through holes, such as figure 1 As shown, in this embodiment, the basic pipeline (11) reserves an air inlet (101) and an air outlet (101 , ), the air inlet (101) and air outlet (101 , ) is used to install the embedded module, the embedded module includes obstacles, gas supply mixing system or ignition head; as a preference, in this embodiment, the third through hole and the fourth through hole are set on the basic pipeline (11), that is, the gas concentration Monitoring port (102) and sensor installation port (102 , ).

[0064] like figure 1 The gas explosion simulation test d...

Embodiment 2

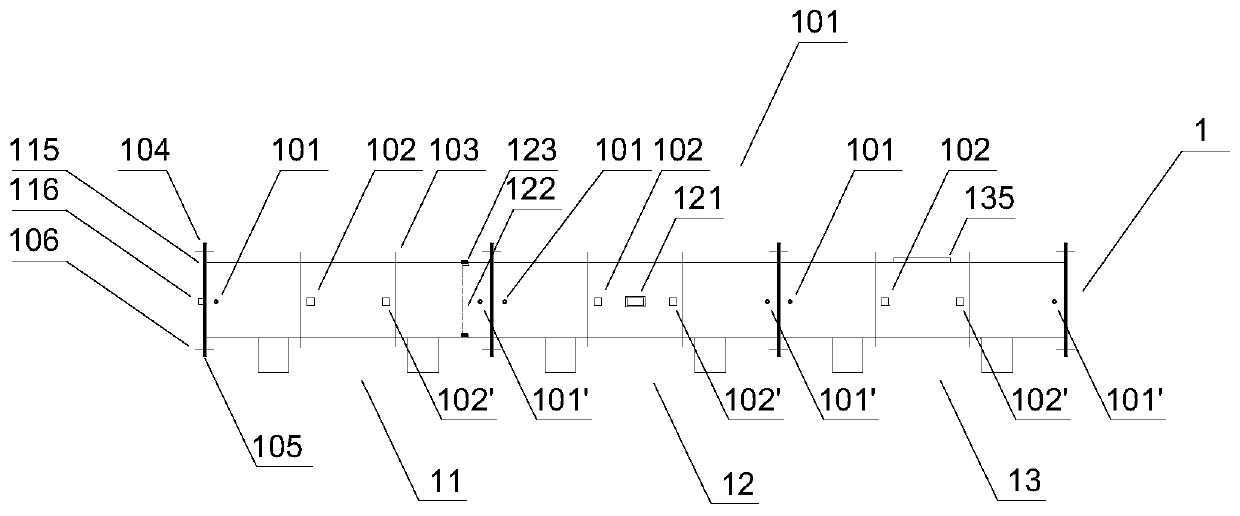

[0070] Embodiment two, on the basis of above embodiment, as figure 2 As shown, this embodiment provides a gas explosion simulation test device in the space of an underground comprehensive pipe gallery, including: a test pipe (1), the test pipe (1) is connected at both ends and includes an explosion venting pipe (13); the explosion venting pipe Both ends of (13) are connected and flanges (104) are provided at both ends, and the explosion venting pipe and other adjacent components are sealed and connected through sealing flanges; the explosion venting pipe (13) reserves an air inlet (101) and air outlet (101 , ), air inlet (101) and air outlet (101 , ) is used to install the embedded module, the embedded module includes obstacles, gas supply mixing system or ignition head; the gas concentration monitoring port (102) and the sensor installation port (102) are set on the explosion vent pipe , ). figure 2 It shows that the test pipeline (1) also includes a basic pipeline (11) ...

Embodiment 3

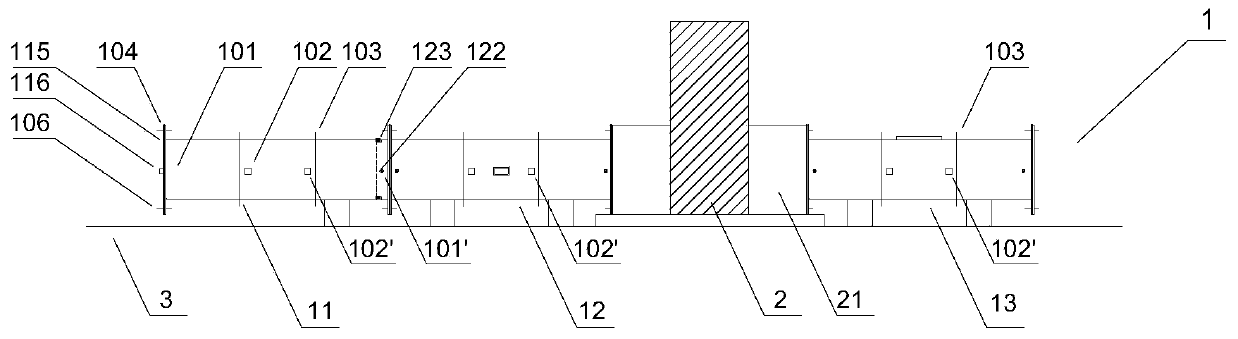

[0075] Embodiment three, on the basis of above embodiment, as image 3 As shown, this embodiment provides a gas explosion simulation test device in the space of an underground comprehensive pipe gallery, including: a test pipe (1) and a transition member (2); the test pipe (1) is connected at both ends, and includes a basic pipe (11), an observation duct (12) and an explosion venting duct (13);

[0076] Both ends of the basic pipeline (11), the observation pipeline (12) and the explosion-venting pipeline (13) are connected and flanges (104) are arranged at both ends, and the foundation pipeline (11), the observation pipeline (12) or the explosion-venting pipeline (13) are sealed and connected with other adjacent components through sealing flanges; the observation pipe (12) is provided with an observation window (121);

[0077] The basic pipeline (11), observation pipeline (12) and explosion venting pipeline (13) are all reserved for installing obstacles or for air inlet (101)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com