Multidirectional opening type sliding rail structure

A spread-out, multi-directional technology, applied in the control of mechanical energy, bearings, electrical components, etc., can solve problems such as stuck vibration, corrosion of sliders and rail beams, gaps, etc., to ensure operation, improve quality and life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples, and the contents mentioned in the embodiments are not intended to limit the present invention.

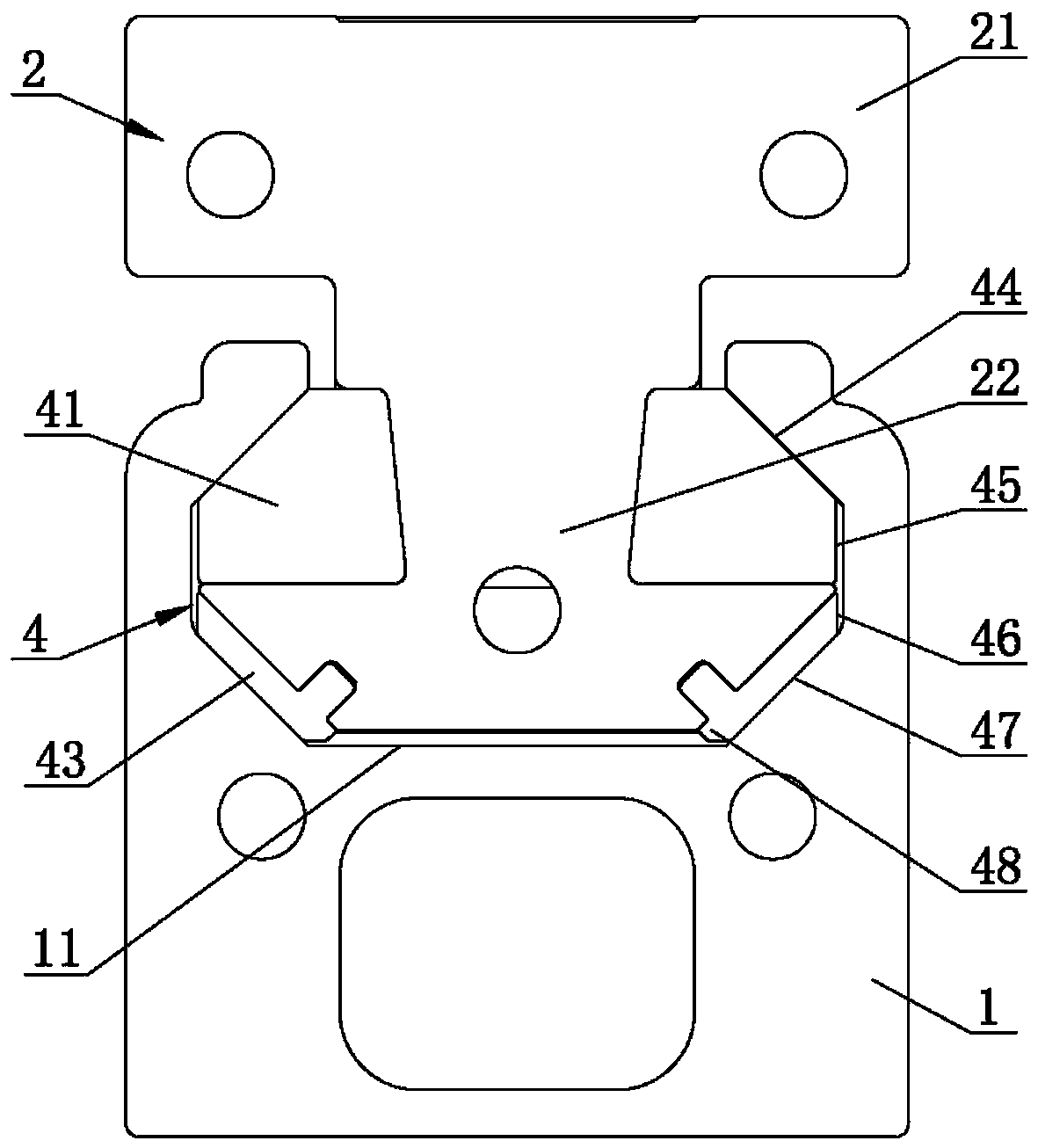

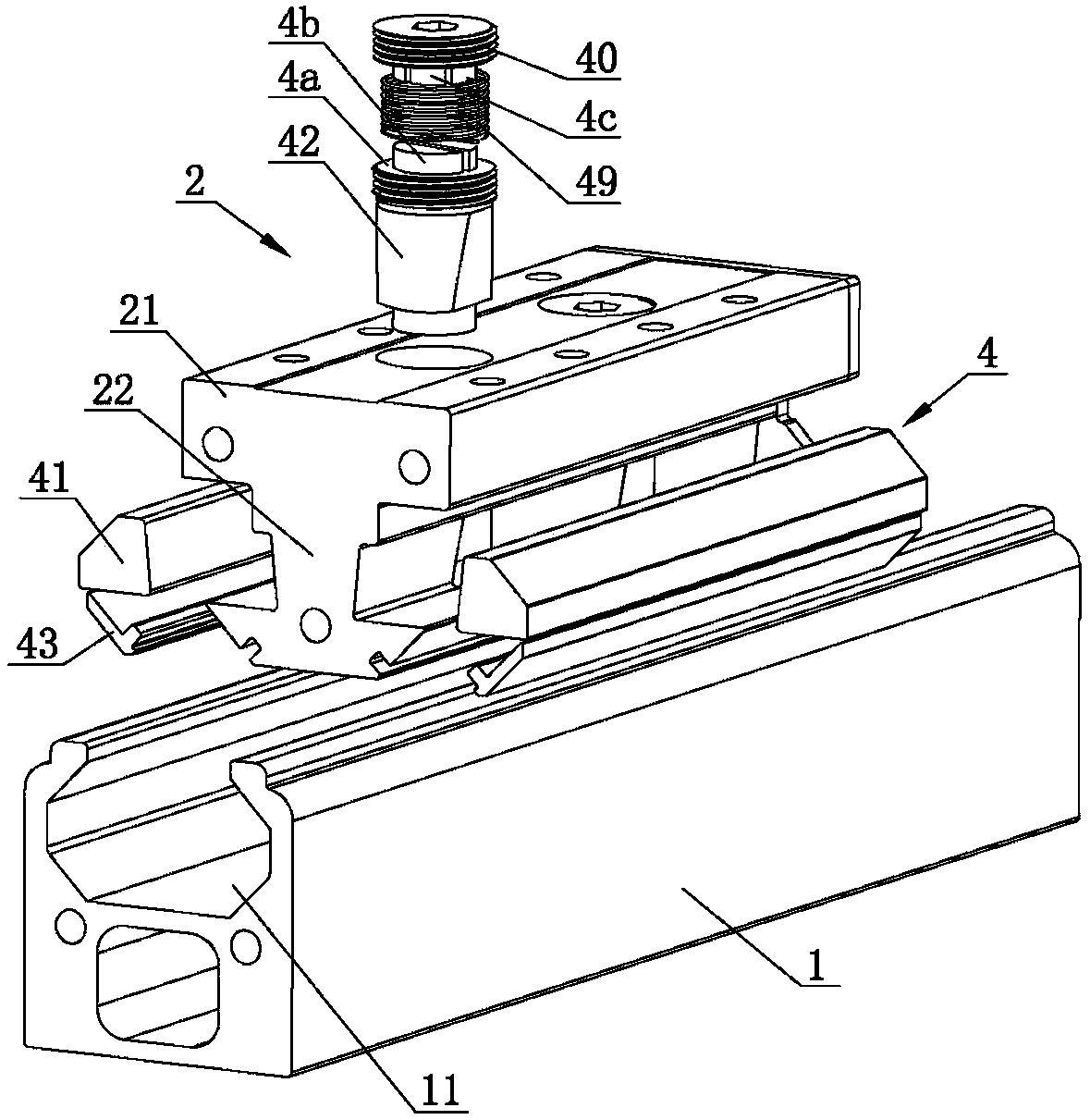

[0022] like Figure 1 to Figure 5 As shown, a multi-directional spread slide rail structure includes a rail beam 1, a slider 2 mounted on the rail beam 1, and a driving device 3 for driving the slider 2 to slide back and forth along the rail beam 1. The rail beam 1 A chute 11 is opened, and the slider 2 includes a bearing part 21 and an embedded body 22 extending from the lower side of the bearing part 21 into the chute 11. The assembly 4 includes a first wear-resistant part 41 mounted on the embedded body 22 and an adjustment part 42 extending from the upper side of the bearing part 21 and driving the first wear-resistant part 41 to be close to the inclined surface of the inner wall of the chute 11 .

[0023] The mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com