Extended anti-stripping prestressed hollow grouting anchor rod and its supporting method

A grouting bolt and prestressing technology, which is used in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of poor grouting quality, unstable connection, long bolt body length, etc., and improve construction quality. and efficiency, reduce the loss of anchoring force, and improve the effect of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

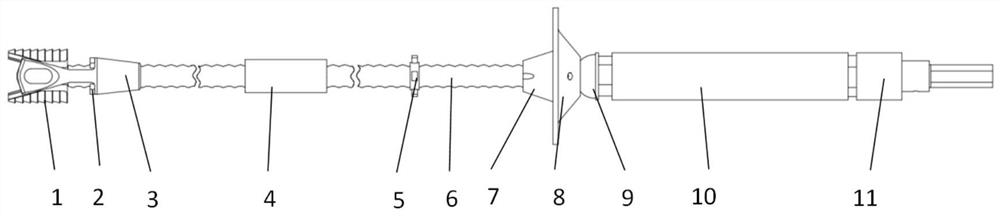

[0040] A kind of extended anti-off prestressed hollow grouting anchor rod, such as figure 1 As shown, it includes: expansion shell clip 1, cushion block 2, expansion shell inner wedge 3, connecting sleeve 4, retainer 5, anchor rod body 6, grout stopper 7, backing plate 8, spherical nut 9, anchor rod connection Device sleeve 10, anchor rod connector 11, etc., wherein:

[0041] 1. Anti-off principle:

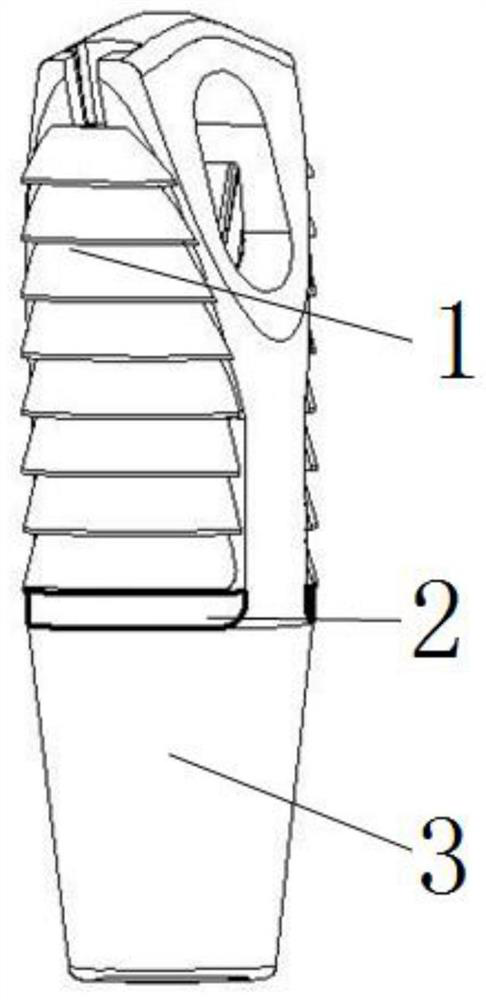

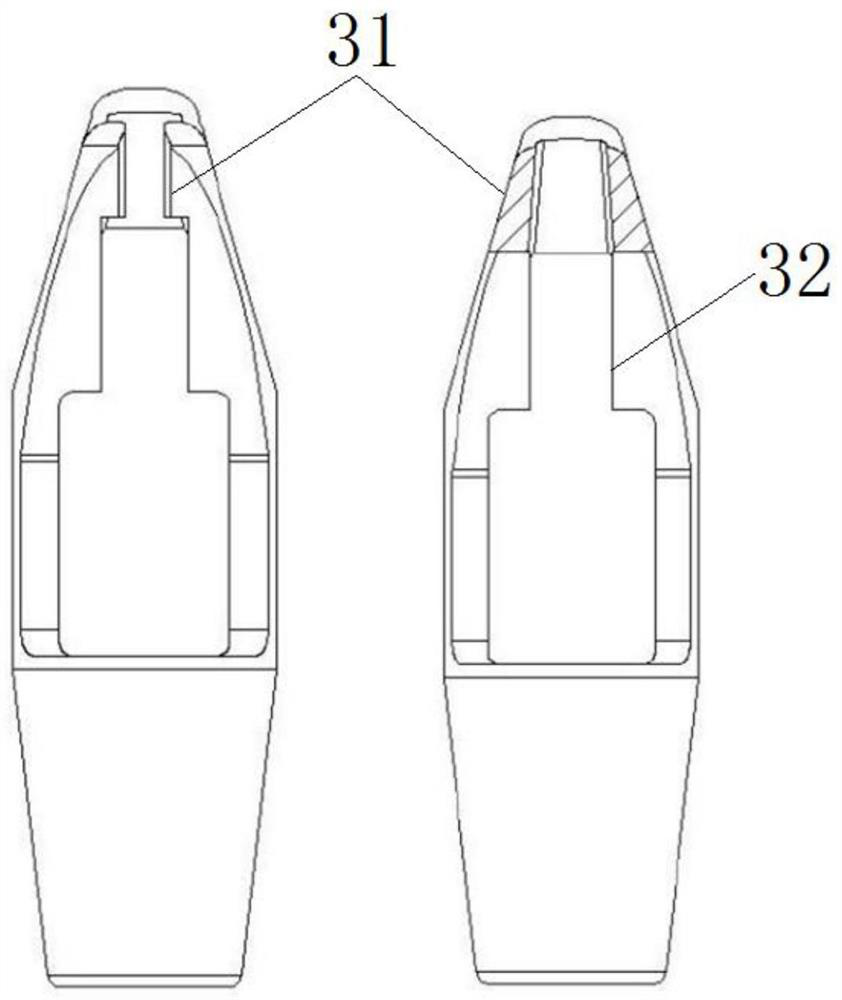

[0042] Such as figure 2 As shown, the expansion shell clip 1, the spacer 2 and the expansion shell inner wedge 3 form an anchor head; wherein: the expansion shell inner wedge 3 has threads at the tail for connecting with the anchor body 6, and the head has symmetrical wedge-shaped grooves 31 and T row groove 32 (such as image 3 shown); the outer circular end of the expansion shell clip 1 has a barb structure 43, and the inside has a wedge-shaped wing 41 and a T row wing 42 (such as Figure 4 shown). The T-shaped groove 32 of the inner wedge 3 of the expansion shell is conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com