Roof beam building structure and construction method

A technology for building structures and beams, applied in building construction, construction, building materials processing, etc., can solve problems such as single installation of auxiliary crossbars, adjust the inclination angle of inclined beams, and affect roof laying, etc., and achieve stable connection. , Guarantee the effect of flatness and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

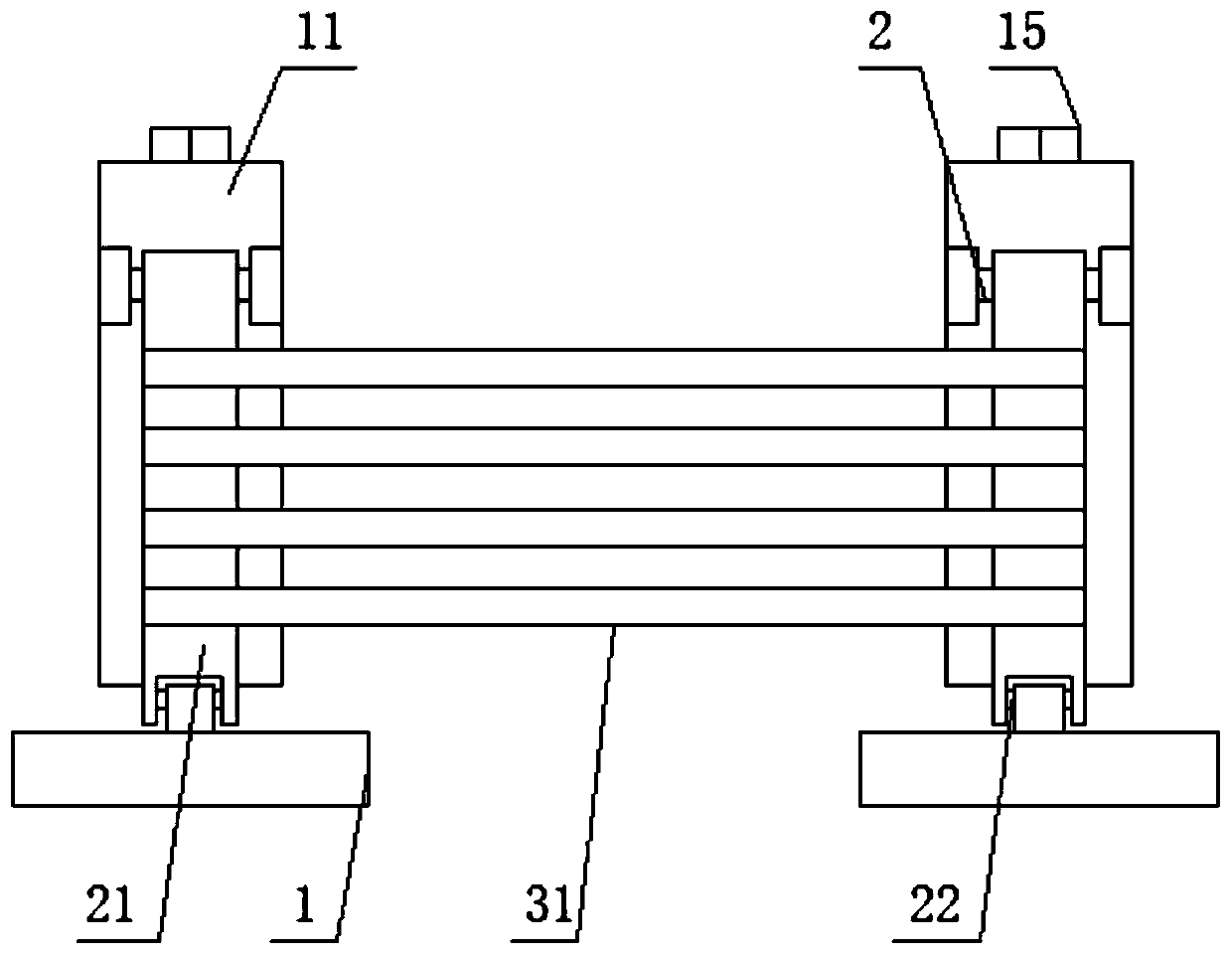

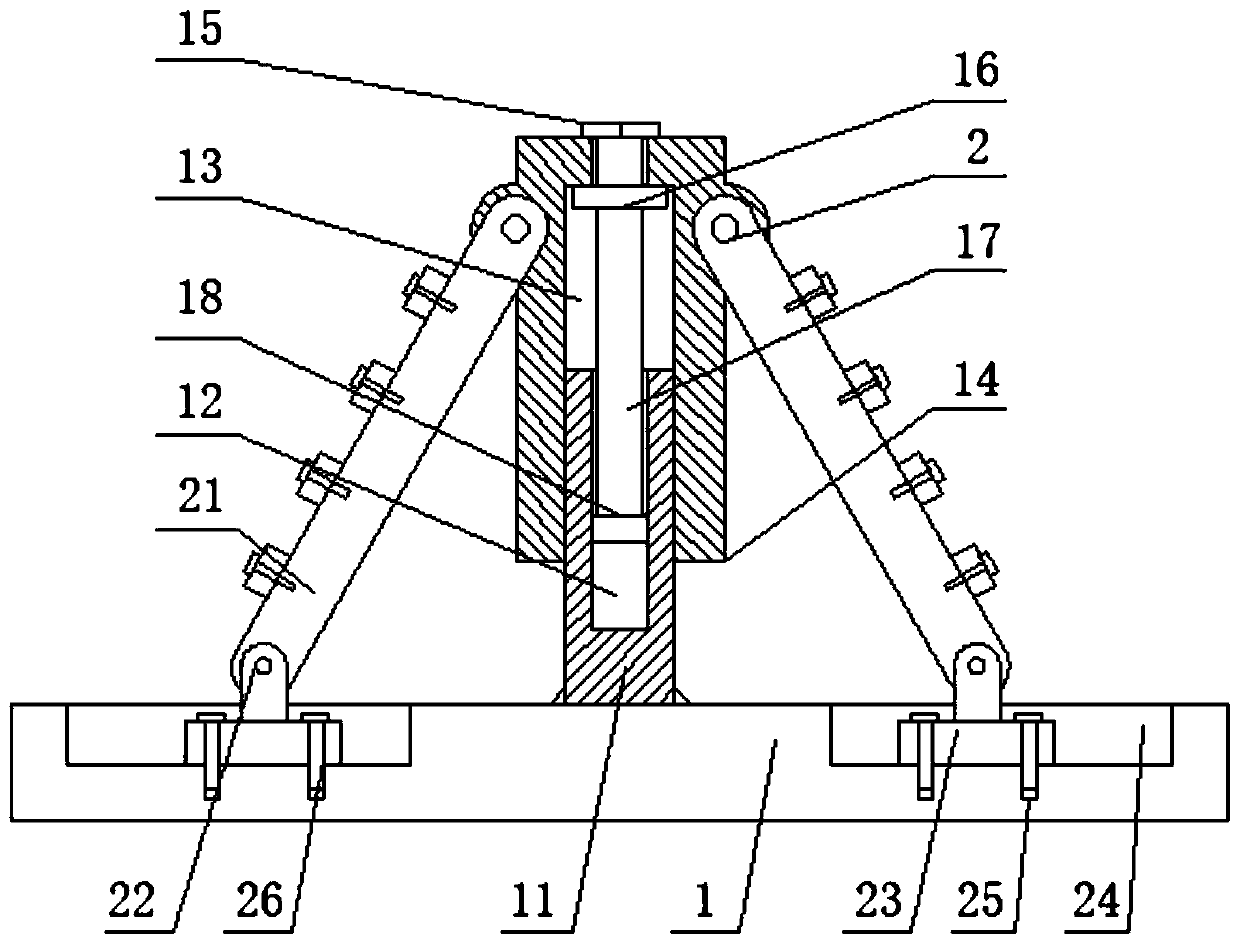

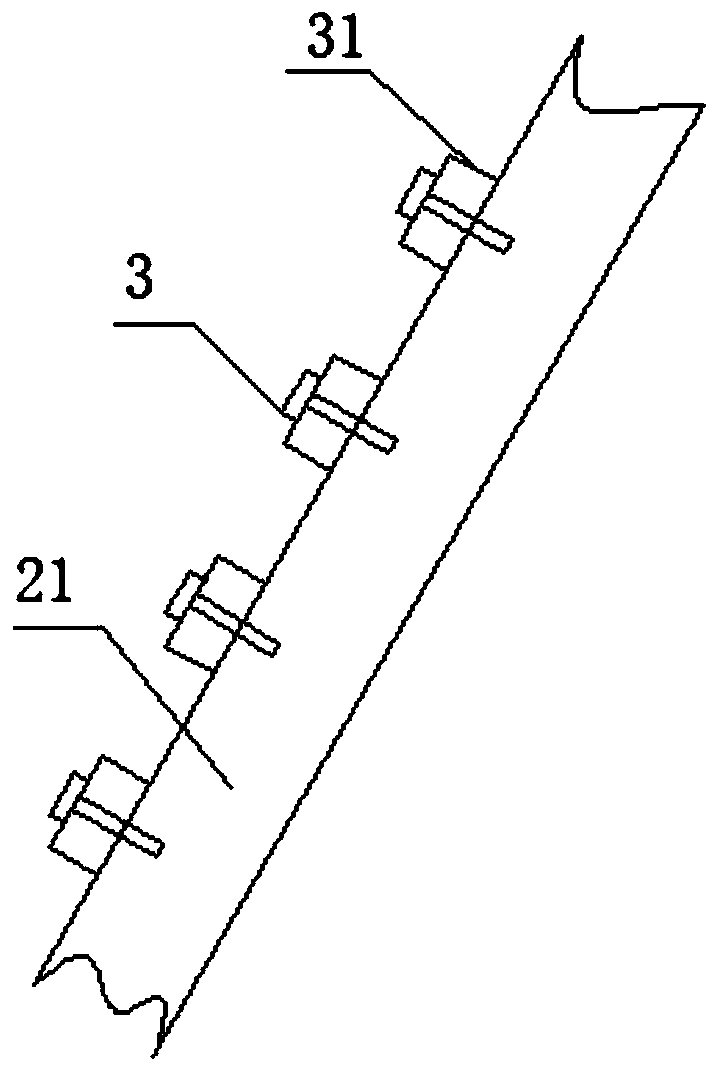

[0047] see figure 2 and image 3 , the upper end of the outer surface of the inclined beam 21 is fixedly installed with the first auxiliary cross bar 31 through the first bolt 3, and the first auxiliary cross bar 31 is connected to the outer surface of the inclined beam 21 at equal intervals, after the inclined beam 21 fixes the angular position , the first auxiliary rods 31 are equidistantly installed on the upper surface of the inclined beam 21 through the first bolts 3, which is convenient for connection and use, stable and efficient.

Embodiment 2

[0049] see figure 2 and Figure 4 , the outer surface side of the inclined beam 21 is fixedly welded with the second auxiliary cross bar 33 through the welding seam 32, and the second auxiliary cross bar 33 is evenly connected between the two inclined beams 21 at equal intervals, so that the angular position of the inclined beam 21 can be fixed Finally, the second auxiliary cross bar 33 is butted to the side position between the two inclined beams 21, and then welded and fixed, which can ensure the stability of the structural frame and at the same time ensure the flatness of the upper surface of the inclined beams 21, which is conducive to laying the roof , high adaptability.

Embodiment 3

[0051] see figure 2 and Figure 5 , the outer upper end of the inclined beam 21 is provided with an auxiliary groove 34, the inner surface of the auxiliary groove 34 is fixedly connected with a third auxiliary cross bar 35, and the upper surface of the inclined beam 21 is fixedly installed with a fixed pressure plate 37 through a second bolt 36, The lower surface of the fixed pressure plate 37 is fixedly pressed and connected to the upper surface of the third auxiliary cross bar 35, after the angle position of the inclined beam 21 is fixed, an auxiliary groove 34 is pre-set on the inclined beam 21, and then the third auxiliary cross bar The two ends of the rod 35 are placed inside the auxiliary groove 34 of the inclined beam 21, which can be placed stably, and then the second bolt 36 is used to fix and install the fixed pressure plate 37, so that the third auxiliary cross bar 35 can be pressed into the auxiliary groove 34 , to avoid prolapse and improve the stability of conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com