Foamless modified sulfonated phenolic resin for drilling fluid and preparation method thereof

A technology of sulfonated phenolic resin and drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of reduced use efficiency and poor inhibition, and achieve convenient use, cost saving, and dissolution and dispersion speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

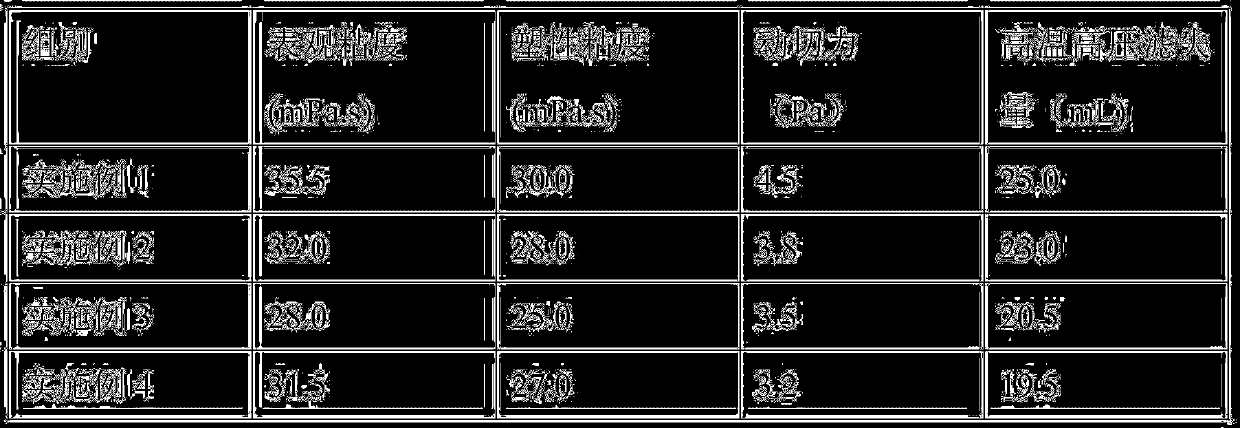

Examples

preparation example Construction

[0019] The present invention also provides a method for preparing a non-foaming modified sulfonated phenolic resin for drilling fluid, comprising the following steps:

[0020] (1) take each raw material by weight ratio;

[0021] (2) Put the phenolic aldehyde and formaldehyde in the reactor and mix them evenly, then dissolve the sodium metabisulfite and anhydrous sodium sulfite with water and slowly inject them into the reactor, gradually raise the temperature of the reactor to 100°C for sulfonation reaction;

[0022] (3) Add nonylphenol polyoxyethylene ether and / or octylphenol polyoxyethylene ether to the reactor, and continue the reaction at 100°C;

[0023] (4) Heating is stopped, the temperature of the reactor is lowered to below 40° C., and then the material is discharged. The liquid product is spray-dried to obtain a solid product, and then the solid product is packed into bags.

[0024] Preferably, the reaction time in the step (2) is 1 hour, and the reaction time in the...

Embodiment 1

[0026] A kind of non-foaming modified sulfonated phenolic resin for drilling fluid, the raw material of described modified sulfonated phenolic resin comprises 110 parts of phenolic formaldehyde, 50 parts of formaldehyde, 80 parts of sodium metabisulfite, 45 parts of anhydrous sodium sulfite, A total of 60 parts of nonylphenol polyoxyethylene ether and octylphenol polyoxyethylene ether, and 30 parts of water.

[0027] Phenolic aldehyde is a foam of phenol and formaldehyde, which has the characteristics of heat resistance, friction resistance, high mechanical strength, electrical insulation, low smoke emission and acid resistance. Sodium metabisulfite dissolves in water to release sulfur dioxide, and sulfur dioxide, anhydrous sodium sulfite and formaldehyde are used as sulfonating agents. The amount of formaldehyde added is excessive, and the excessive formaldehyde and the sulfonated phenolic novolac continue to undergo polycondensation reaction, making the sulfonated phenolic n...

Embodiment 2

[0035] A kind of non-foaming modified sulfonated phenolic resin for drilling fluid, the raw material of described modified sulfonated phenolic resin comprises 130 parts of phenolic aldehyde, 70 parts of formaldehyde, 110 parts of sodium metabisulfite, 70 parts of anhydrous sodium sulfite, 90 parts of nonylphenol polyoxyethylene ether, 60 parts of water.

[0036] The preparation method of the above-mentioned non-foaming modified sulfonated phenolic resin for drilling fluid comprises the following steps:

[0037] (1) take each raw material by weight ratio;

[0038] (2) Put phenolic aldehyde and formaldehyde in the reactor and mix evenly, then dissolve sodium metabisulfite and anhydrous sodium sulfite with water and slowly inject into the reactor, gradually raise the temperature of the reactor to 100°C and heat and reflux for 1 hour to carry out the sulfonation reaction ;

[0039] (3) Add nonylphenol polyoxyethylene ether into the reaction kettle, continue to heat and reflux at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com