Circulating reciprocating type electromagnetic vibration feeder

An electromagnetic vibration and reciprocating technology, applied in chemical instruments and methods, solid separation, loading/unloading, etc., can solve the problems of blocked discharge funnel, discontinuity, uneven peanuts, etc., and achieve the effect of preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be further described below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

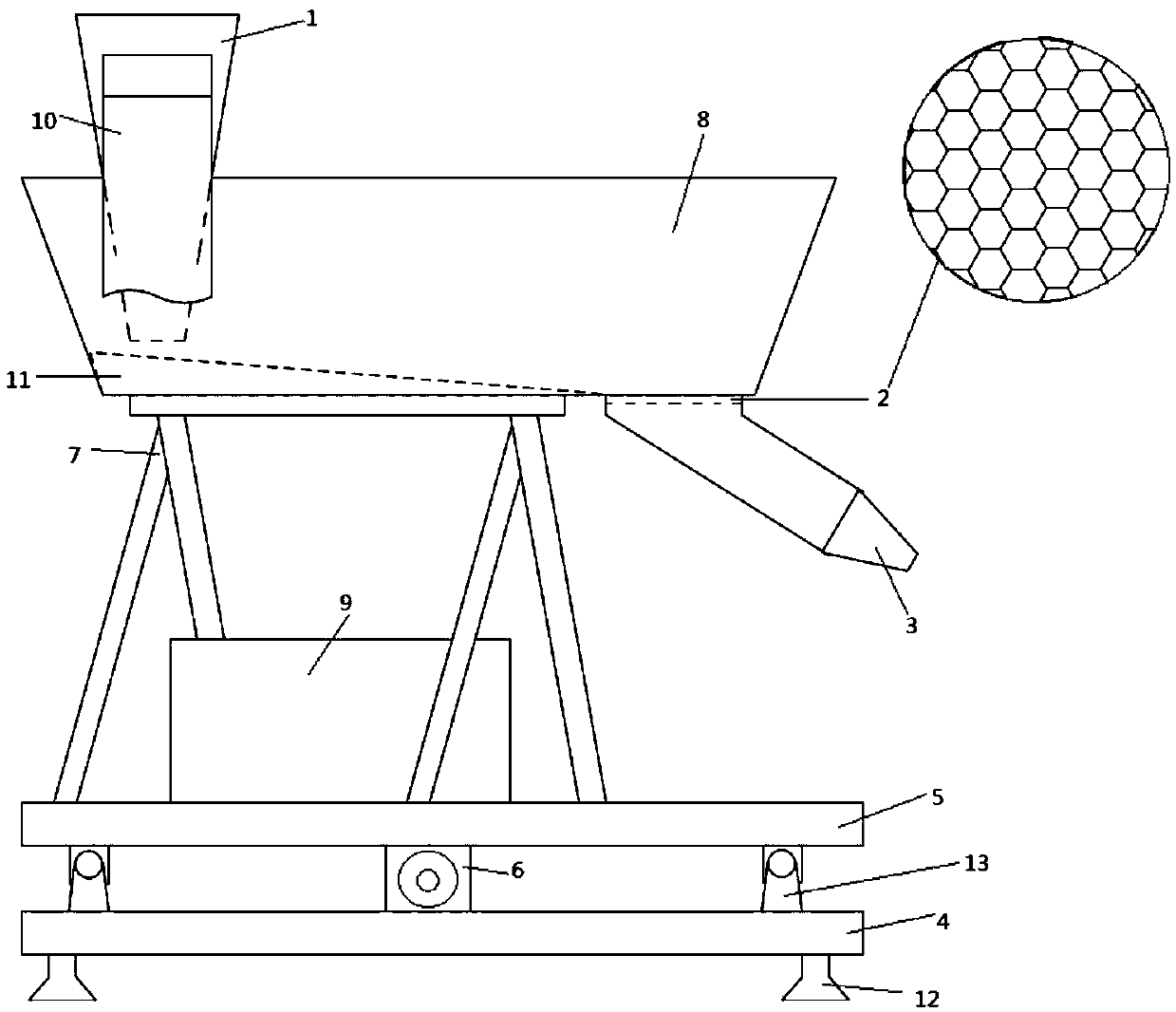

[0025] See figure 1 , figure 1 It is a structural schematic diagram of a reciprocating electromagnetic vibration feeder according to an embodiment of the present invention. As shown in the figure, the reciprocating electromagnetic vibration feeder of the present invention includes a feeding funnel 1, a moving screen box, a vibrating The screen 2 and the discharge funnel 3, the feed funnel 1 is fixed above the movable screen box, the discharge funnel 3 is arranged at the bottom of the movable screen box, and the vibrating screen 2 is detachably installed between the movable screen box and the outlet. Between the hoppers 3.

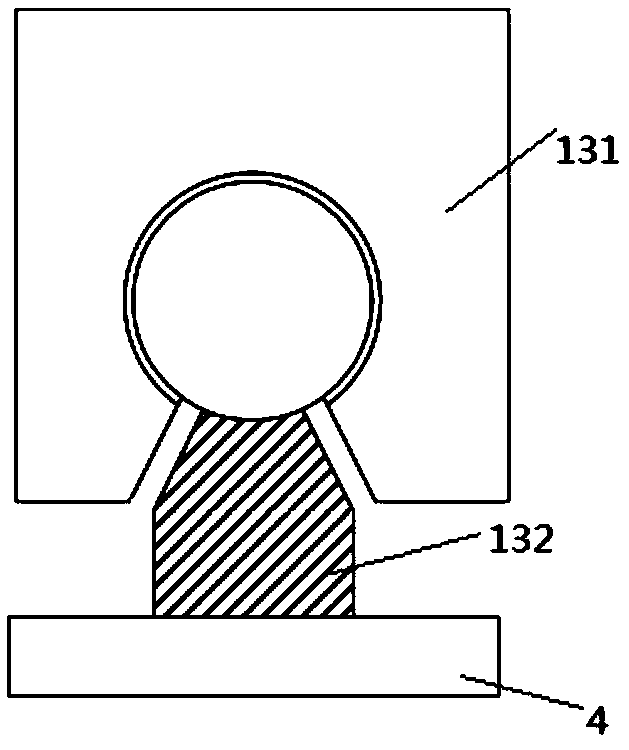

[0026] Specifically, the mobile screen box includes a mobile structure base 4, a feeder base 5, a motor 6, a leaf spring 7, a screen box main body 8, and an electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com