Integrated cutting, sealing and printing machine

An all-in-one machine and printing mechanism technology, applied in packaging sealing/fastening, external support, packaging, etc., can solve problems such as cumbersome procedures, affecting production efficiency, and inconvenient operation, so as to achieve rigorous and reasonable design, improve production efficiency, and prevent clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

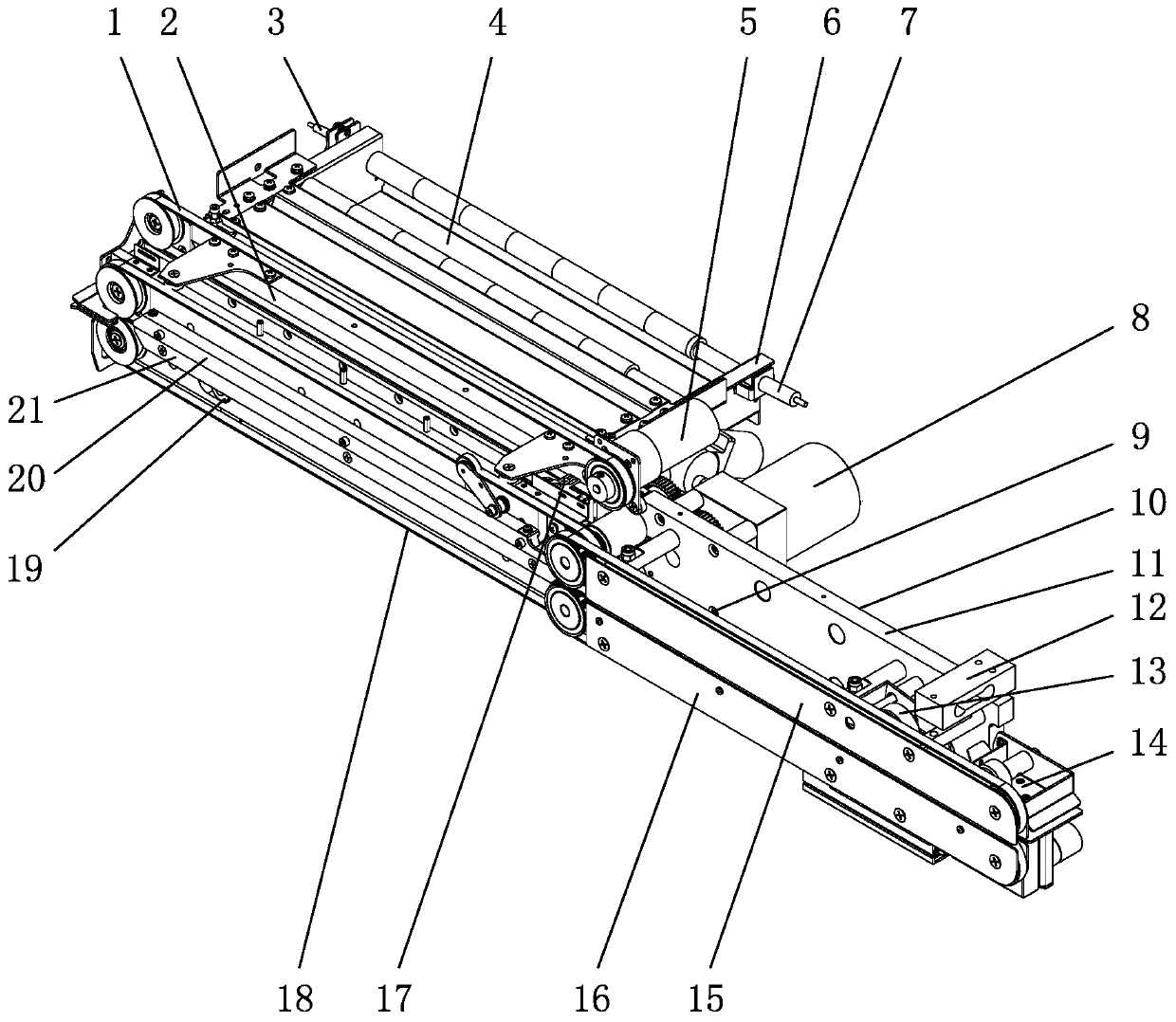

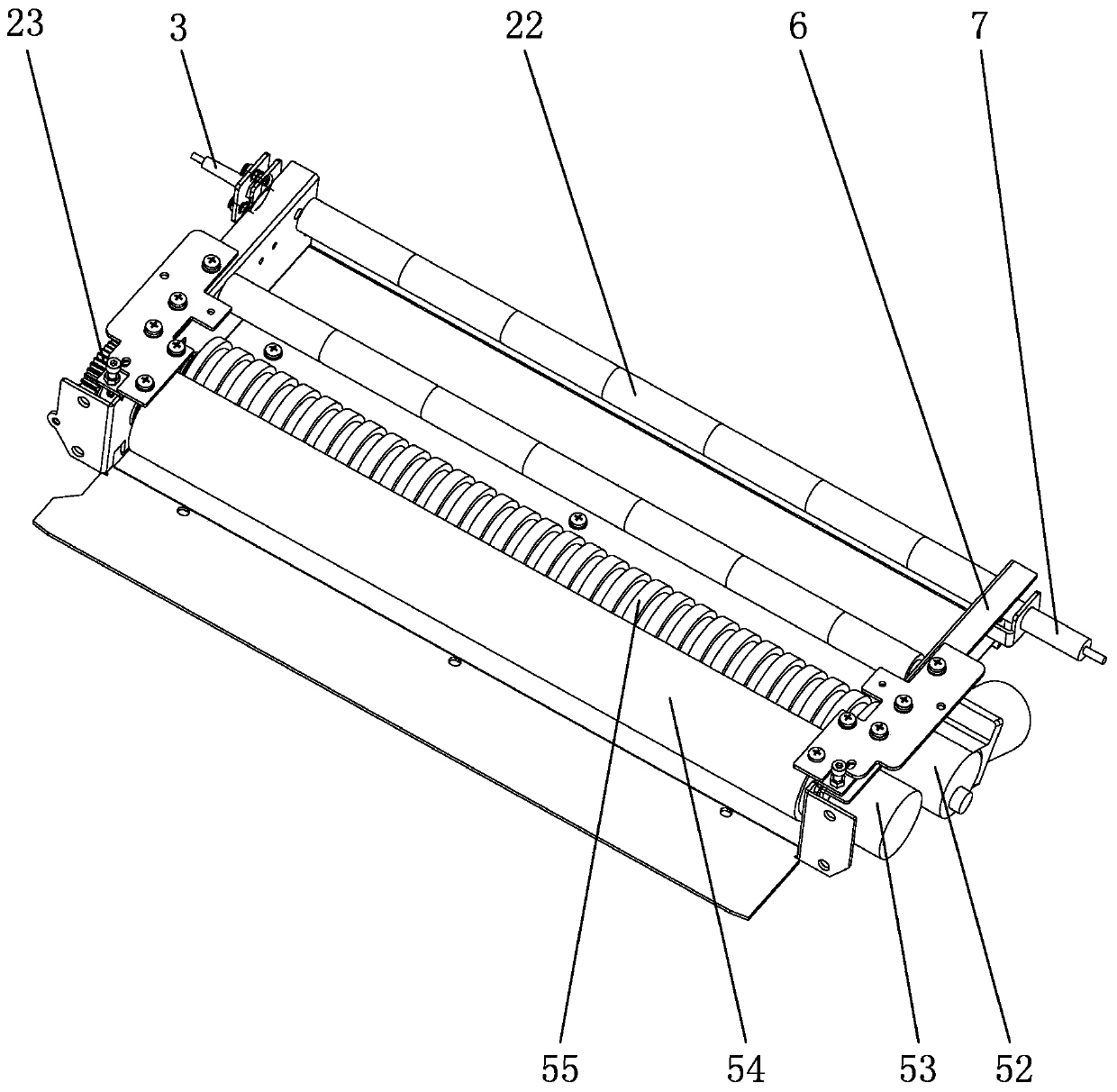

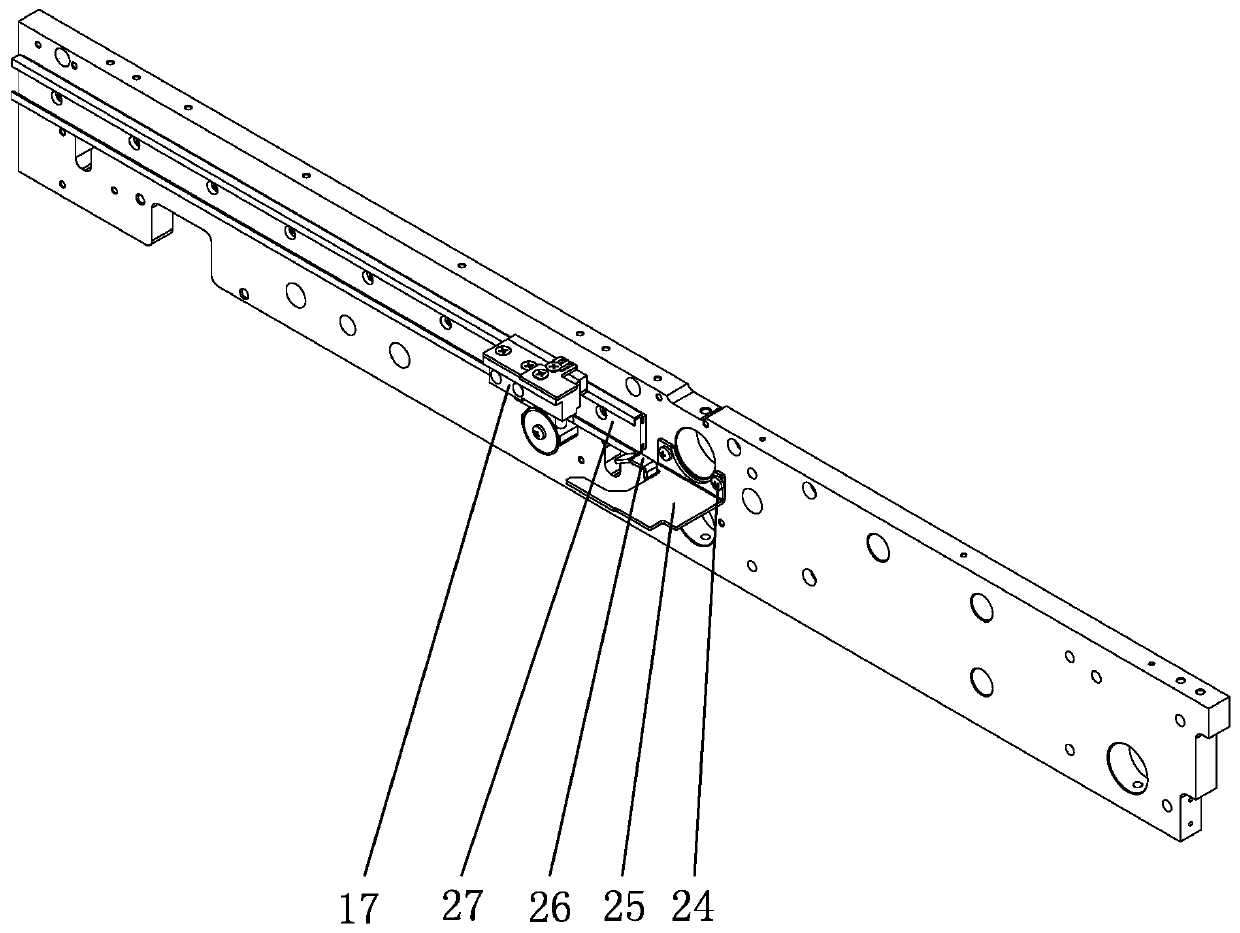

[0024] like Figure 1-7 As shown, a cutting, sealing and printing all-in-one machine includes a substrate 11, a feeding mechanism 4, and a sealing and printing mechanism 10. The feeding mechanism 4 and the sealing and printing mechanism 10 are fixed on both sides of the substrate 11 in dislocation, and the substrate 11 is provided with a cutting mechanism 2. With clamping conveying mechanism 18, cutting mechanism 2, clamping conveying mechanism 18 and sealing printing mechanism 10 are arranged on the same side of substrate 11, and feeding mechanism 4 includes feeding bracket 6, worm gear motor 52, encoder 53, gear 23 , Tail material launch sensor 7 and tail material receiving sensor 3, tail material launch sensor 7 and tail material receiving sensor 3 are arranged on both sides of feed support 6, cutting mechanism 2 is provided with synchronous belt driving devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com