A Helicopter Rotor Blade Variation Lower Reverse Tip Drive Mechanism Based on Centrifugal Mass Block

A helicopter rotor, centrifugal mass technology, applied in the direction of rotorcraft, motor vehicles, wing adjustment, etc., can solve the problems of difficult to provide driving power tip, large recovery torque, narrow blade space, etc., to ensure safety, reduce Small overall size, the effect of reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

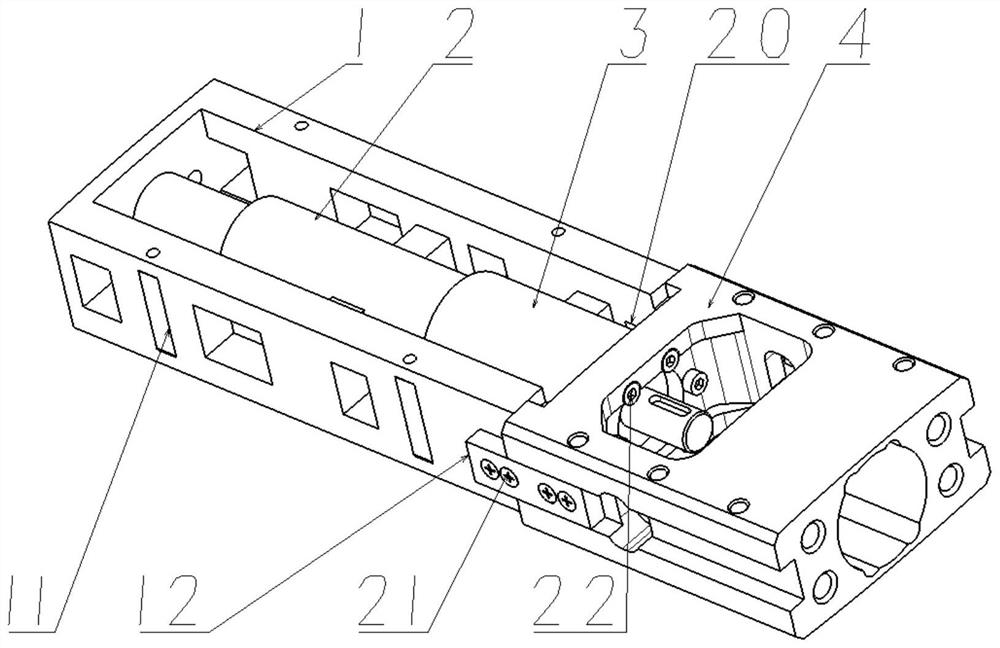

[0031] In order to clearly illustrate the technical features of the present patent, the present patent will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

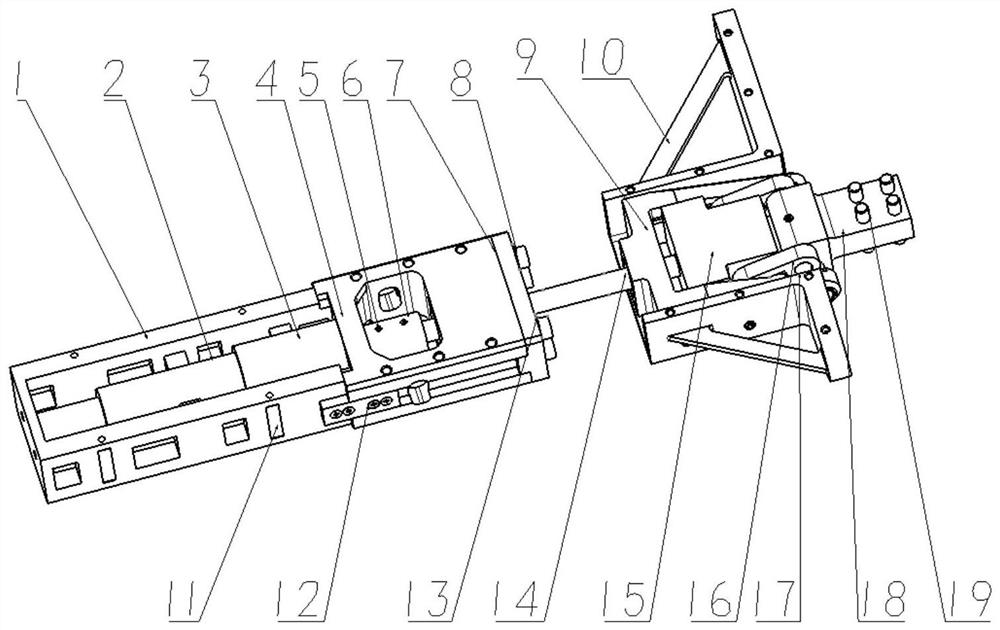

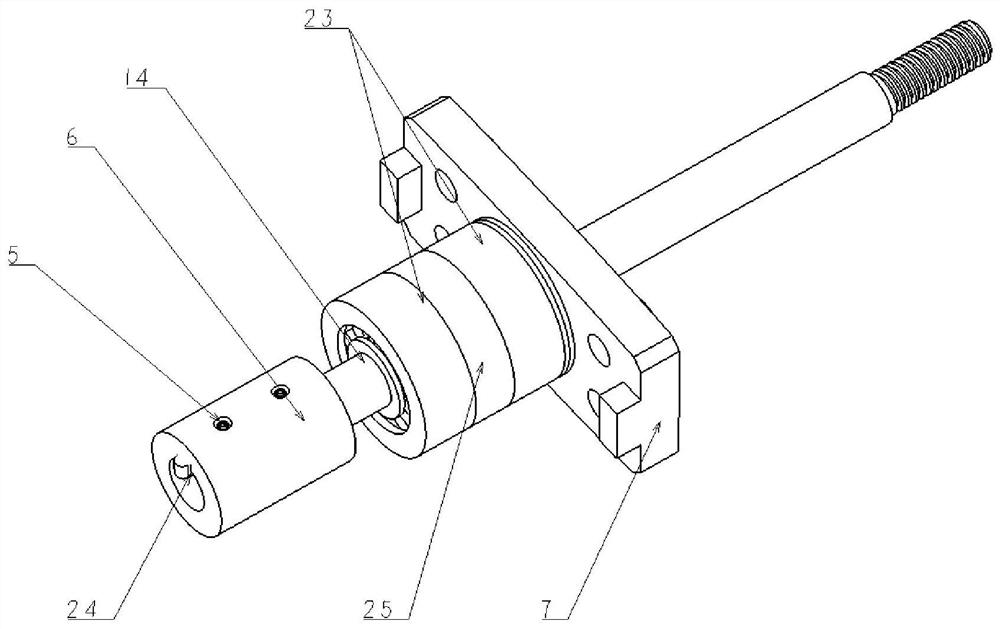

[0032] The present invention is as Figure 1-9 As shown, the rotor blade of the helicopter includes a blade base 33 and a blade tip 36 provided at one end of the blade base, and the lower anti-drive mechanism includes a driver unit and a blade tip actuator unit, and the driver unit is connected to the The blade base body, the blade tip actuator unit is respectively connected with the blade base body and the blade tip, and the blade tip actuator unit is reciprocated and flipped under the drive of the driver unit to realize the change of the lower reverse angle.

[0033] The blade tip actuator unit includes a centrifugal mass 15, a linkage assembly and a blade tip actuating head 18;

[0034] The centrifugal mass 15 is slidably connected in the blade base 33 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com