Injection mold and injection molding machine thereof

A technology for injection molds and mold splitting, which is applied in the field of injection molds and injection molding machines, can solve problems such as polluting products, and achieve the effects of improving efficiency, convenient use, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides an injection molding machine, including: the injection mold described below.

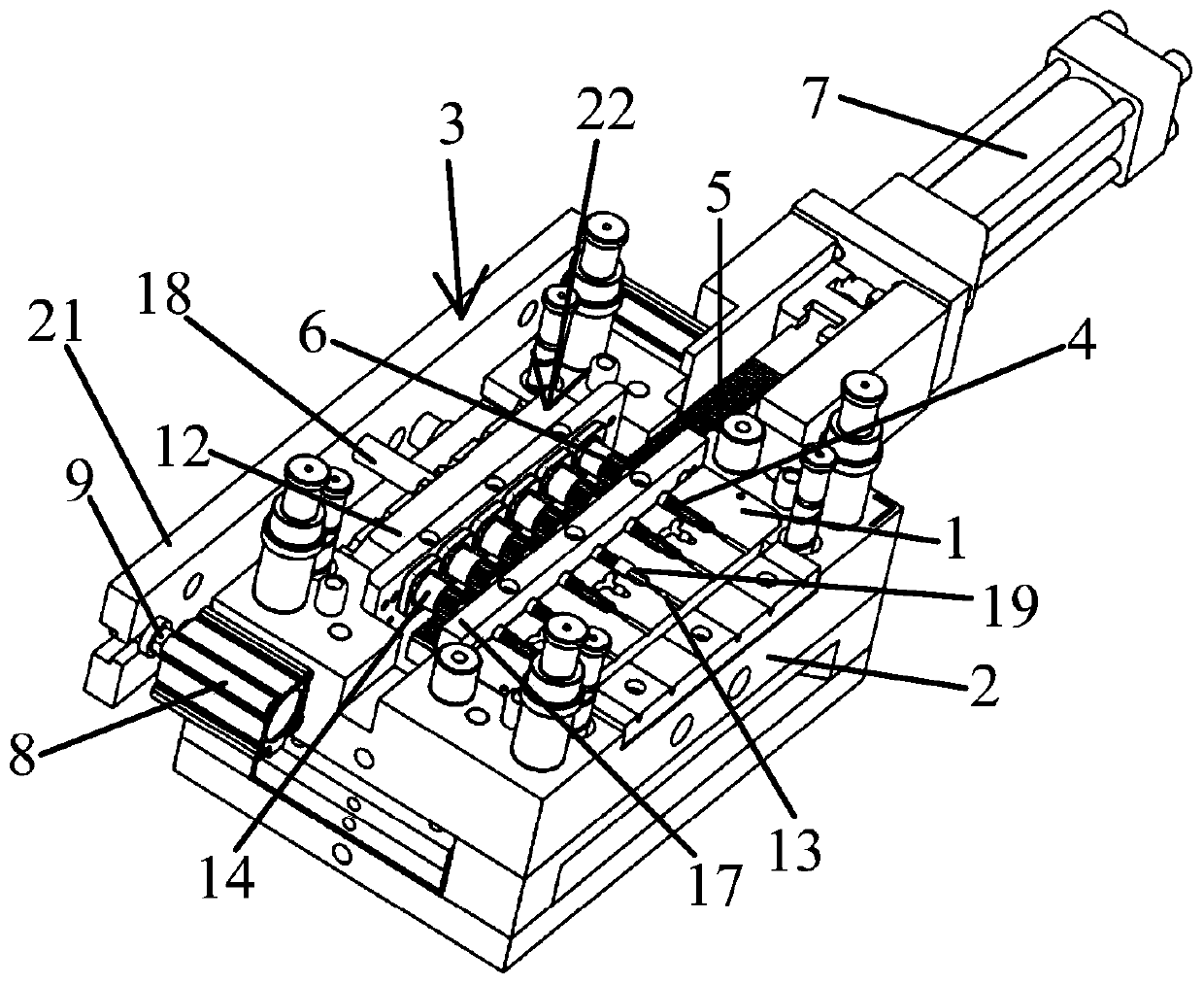

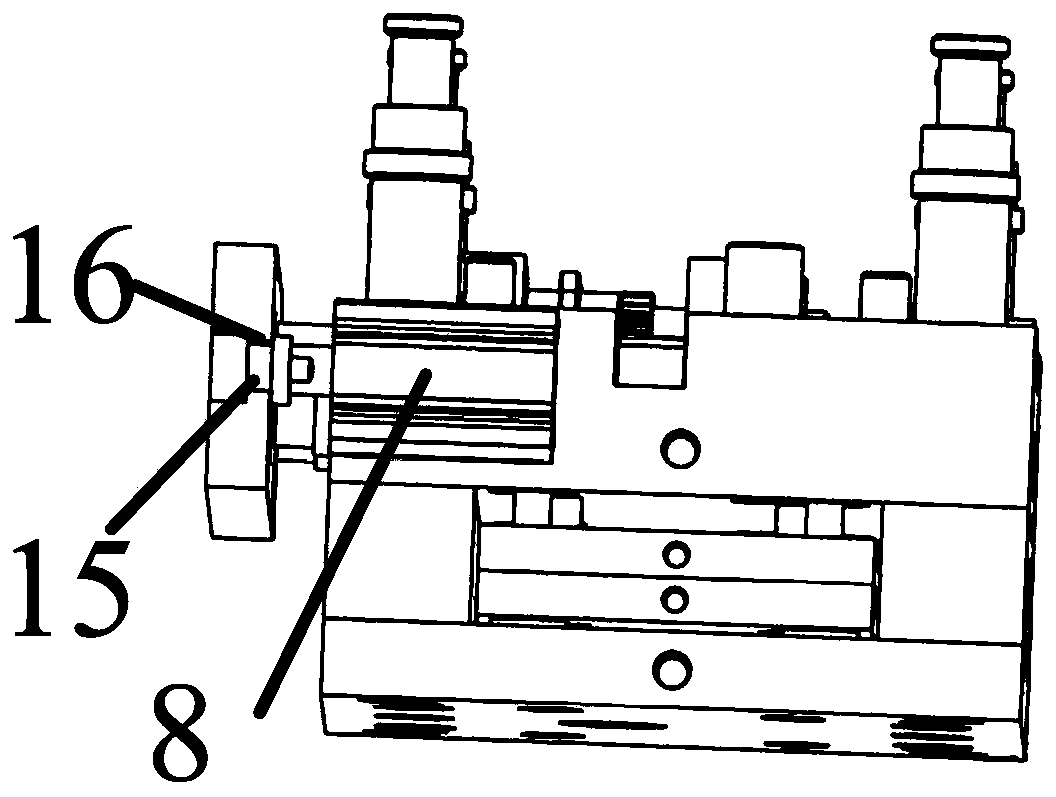

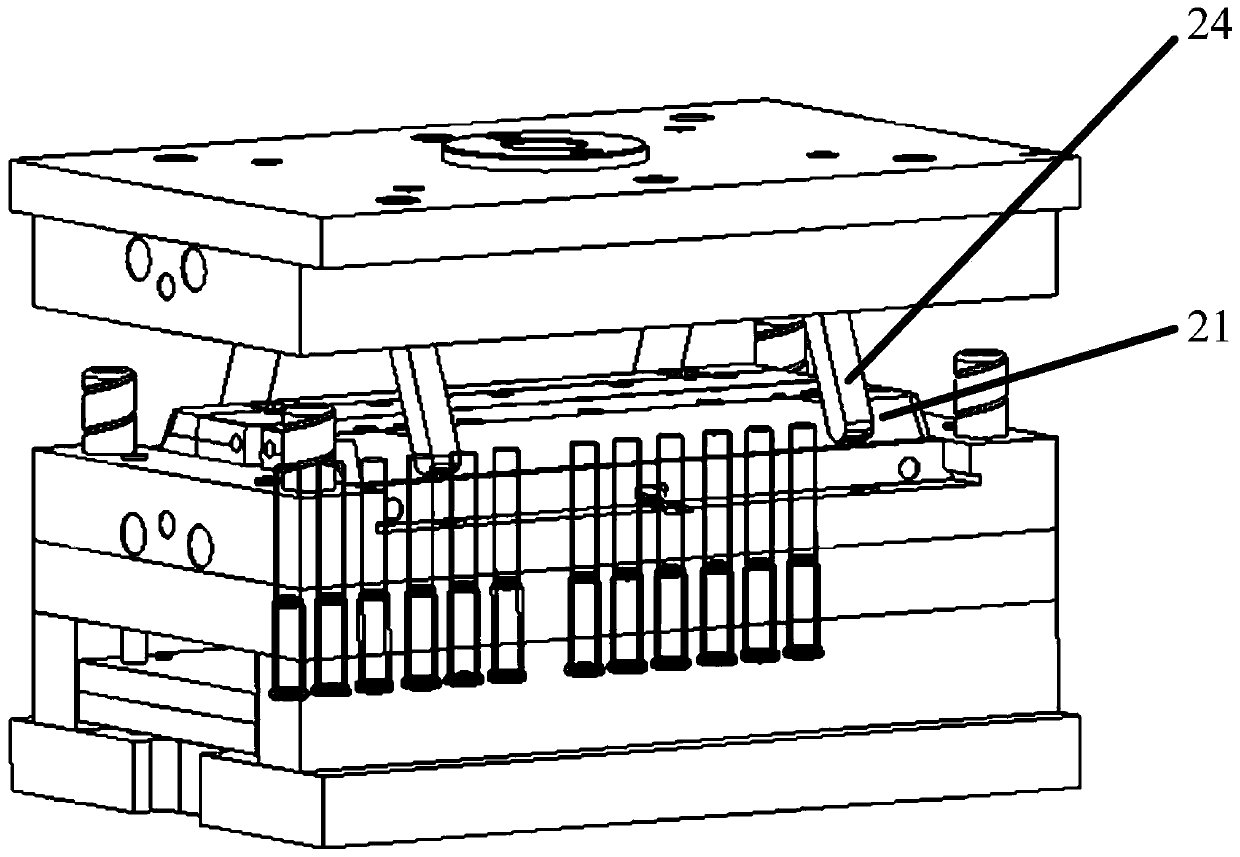

[0035] The injection mold such as figure 1 As shown, it includes: a cavity 1; a core 4, which is accommodated in the cavity 1 to form an injection molding cavity, and the core 4 has a mold clamping position close to the cavity 1 and a part far away from Die position; core-pulling structure 22, connected with the transmission of the core 4, to drive the core 4 to rotate along its circumferential direction, so as to switch between the mold clamping position and the mold splitting position. There are technologies such as image 3 As shown, the slider cavity is composed of a group of sliding movable blocks 21 arranged oppositely. The above-mentioned sliding movable blocks 21 are generally arranged on the lower mold. Moving up and down, during the movement, the square guide post 24 slides in the inclined slot, thereby pushing the sliding movable block 21 to move in the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com