Mechanical arm clamp for motor rotor production

A technology for motor rotors and manipulators, applied in manipulators, program-controlled manipulators, manufacturing stator/rotor bodies, etc., can solve problems affecting product quality, high labor intensity of workers, many processing and assembly processes, etc., to facilitate the operation of workers , Reduce the labor intensity of workers, reduce the effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

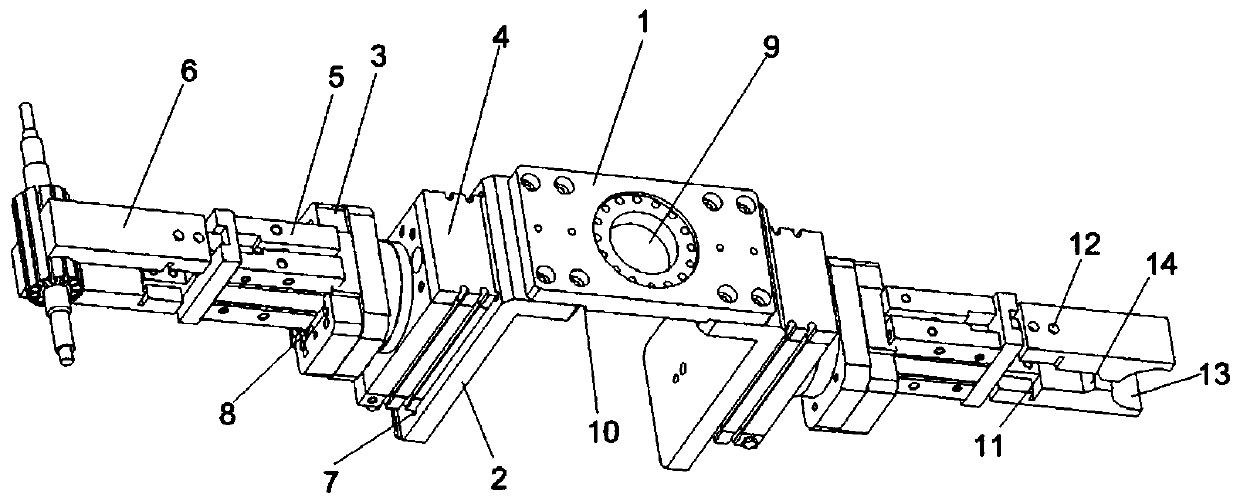

[0027] Such as figure 1 As shown, a manipulator fixture for motor rotor production includes a rotating connecting plate 1 and a rotor clamping structure installed symmetrically at both ends of the rotating connecting plate 1. The rotor clamping structure includes clamping jaws 6, driving jaws 6 for clamping and loosening The pneumatic finger 5 and the rotating cylinder 4 that drives the pneumatic finger 5 to rotate, the pneumatic finger 5 is installed on the rotating cylinder 4 through the fixed plate 3, and the rotating cylinder 4 is installed on the rotating connecting plate 1 through the mounting plate 2. The mounting plate 2 is L-shaped, and the top of the short side of the mounting plate 2 is fixed on the bottom of the rotating connecting plate 1 , and the rotary cylinder 4 is fixed on the outside of the long side of the mounting plate 2 . The outside of the long side of the mounting plate 2 is provided with a rotary cylinder mounting groove 7 matching the rotary cylinder...

Embodiment 2

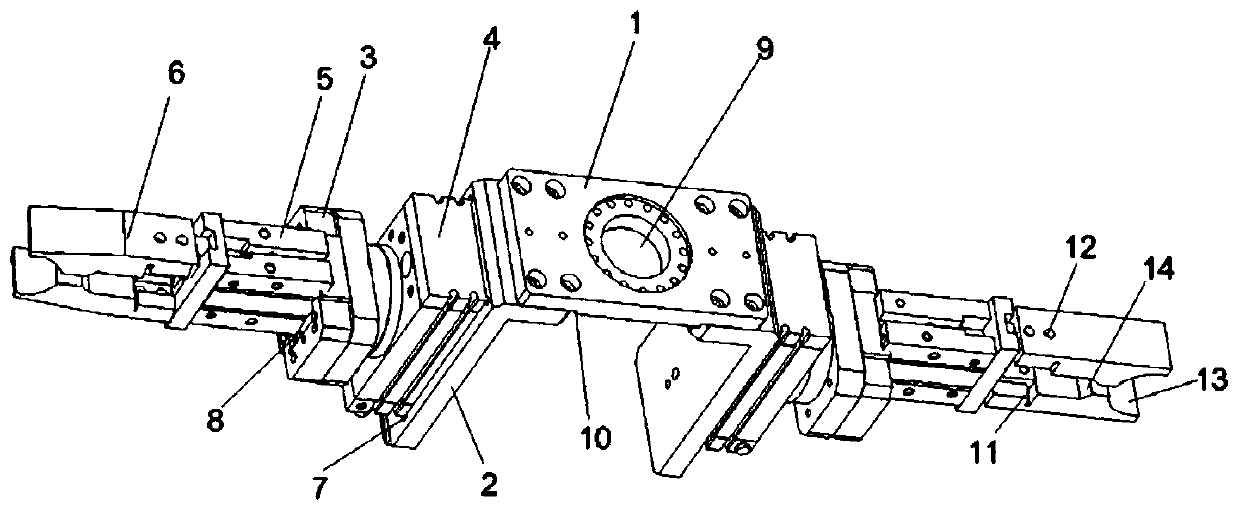

[0029] Such as figure 2 As shown, the front end of the outer surface of one side of the jaw 6 is inclined, and the middle part of the inner surface is provided with a limit step 14, while the outer surface of the other side of the jaw 6 is flat, and the middle part of the inner surface is provided with a limit step 14.

Embodiment 3

[0031] The jaws on both sides are all flat on the outside, and the middle part on the inside is flat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com