A rotatable clamping device for milling

A clamping device and milling technology, applied in the direction of positioning device, clamping, manufacturing tools, etc., can solve the problems of inconvenience, low work efficiency, loss of precision, etc., achieve comfortable processing, improve processing efficiency, and avoid re-alignment knife effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] All features disclosed in this specification, or all disclosed methods or steps in the process, except for mutually exclusive features and / or steps, can be combined in any manner.

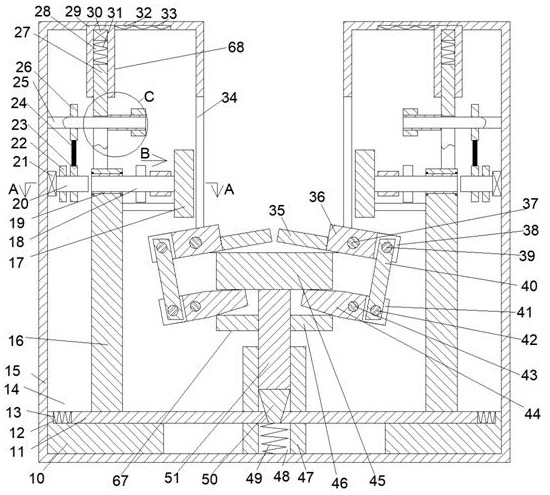

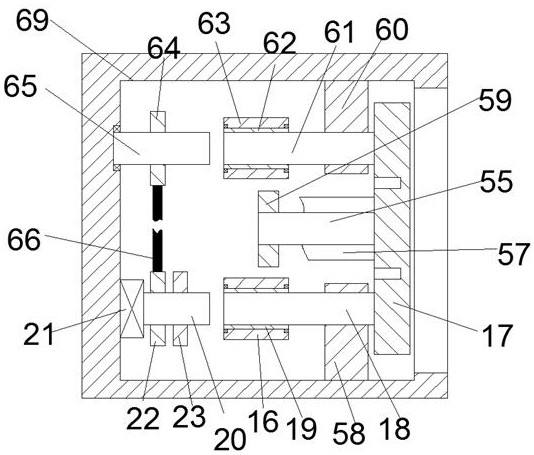

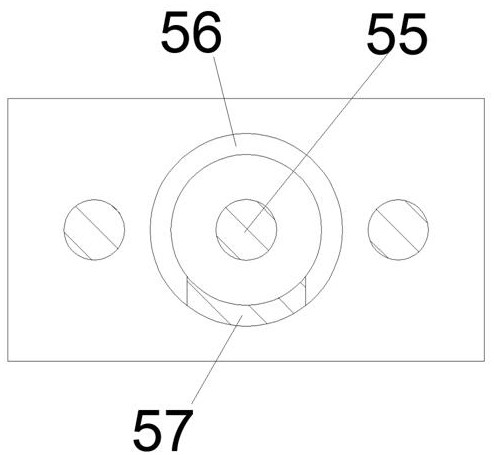

[0017] Combine below Figure 1-4 The present invention will be described in detail. For the convenience of description, the following directions are specified as follows: figure 1 The vertical, horizontal, front and rear directions of the projection relationship are the same.

[0018] A clamping device that can rotate during milling of the device of the present invention includes a mounting box 15 in which a mounting cavity 14 is provided, and the mounting cavity 14 is provided with a clamping platform and an effective support The load-bearing mechanism 67 on which the workpiece is stressed during the machining process. The load-bearing mechanism 67 includes a load-bearing box 47 fixedly installed on the bottom end wall of the mounting cavity 14. The load-bearing box 47 is provided with a load-be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com