Device and method used for killing African swine fever viruses in feedstuffs

A technology for African swine fever virus and feed raw materials, which is applied in the field of devices for killing African swine fever virus in feed raw materials, can solve the problems of increased cost and long feed processing and production cycle, reduce exhaust gas emissions, and improve heat energy utilization Efficiency, reduced stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

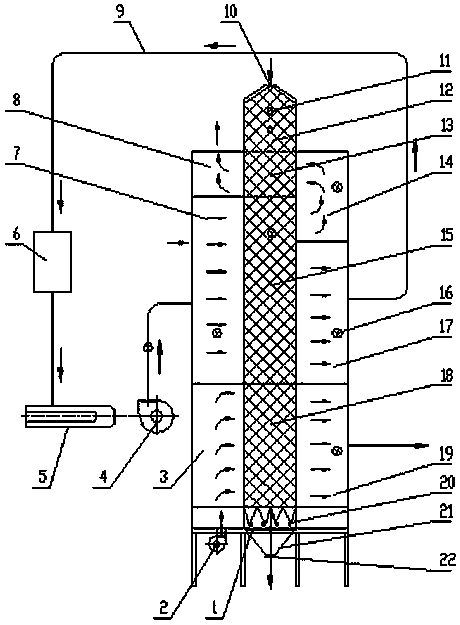

[0039] as attached figure 1 As shown, the heating tower 1 is the main equipment of the device, including a vertical tower with a rectangular cross section. The top of the tower is provided with a feed port 10 and the bottom is provided with a discharge port 22 . The heating tower 1 can be divided into a storage section 12 , a preheating section 13 , a heating section 15 , a cooling section 18 , a discharge section 20 , and a hopper 21 from top to bottom according to the working area.

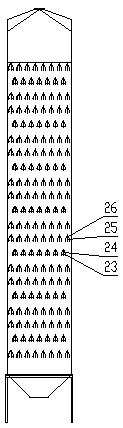

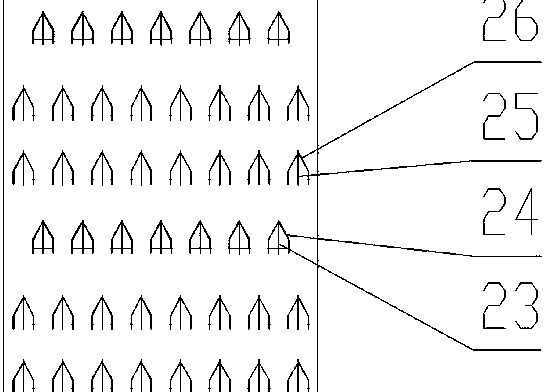

[0040] Such as figure 2 image 3 As shown, in the middle of the preheating section 13, the heating section 15, and the cooling section 18, from top to bottom, rows of air inlet angular boxes 24 and air outlet angular boxes 26 are arranged horizontally and alternately in parallel. The angular box is made of thin steel plate, arranged in an inverted V shape, pentagonal, including two left and right slopes on the upper part and two left and right side walls extending vertically downward along th...

Embodiment 2

[0051] The device is equipped with a material level monitoring device 11 in the material storage section 12 of the heating tower 1, which monitors the highest and lowest material levels, and is linked with the feeding system outside the heating tower. When the raw material reaches the high material level, the feeding is automatically stopped; When the material level drops to a low material level, the feeding is automatically restarted to keep the raw material level in the storage section 12 at a suitable position.

Embodiment 3

[0053] Hot air and exhaust temperature and humidity monitoring devices are installed in each air chamber and air duct to monitor hot air and exhaust temperature and humidity online in real time. The monitoring signal is linked with the operation control of the hot blast stove 5. When the temperature of the hot blast is higher than the set temperature, the hot blast stove 5 automatically Reduce the amount of fuel, and the temperature of the hot blast decreases; when the temperature of the hot blast is lower than the set temperature, the hot blast stove 5 automatically increases the amount of fuel, and the temperature of the hot blast rises, thereby automatically adjusting the temperature of the output hot blast from the hot blast stove 5 to keep stable. The circulating hot air discharged from the heating tower 1 inevitably contains particles such as dust impurities, and the dust collector 6 is used to remove dust impurities in the circulating hot air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com